High-strength anisotropic aerogel type wood structure and preparation method thereof

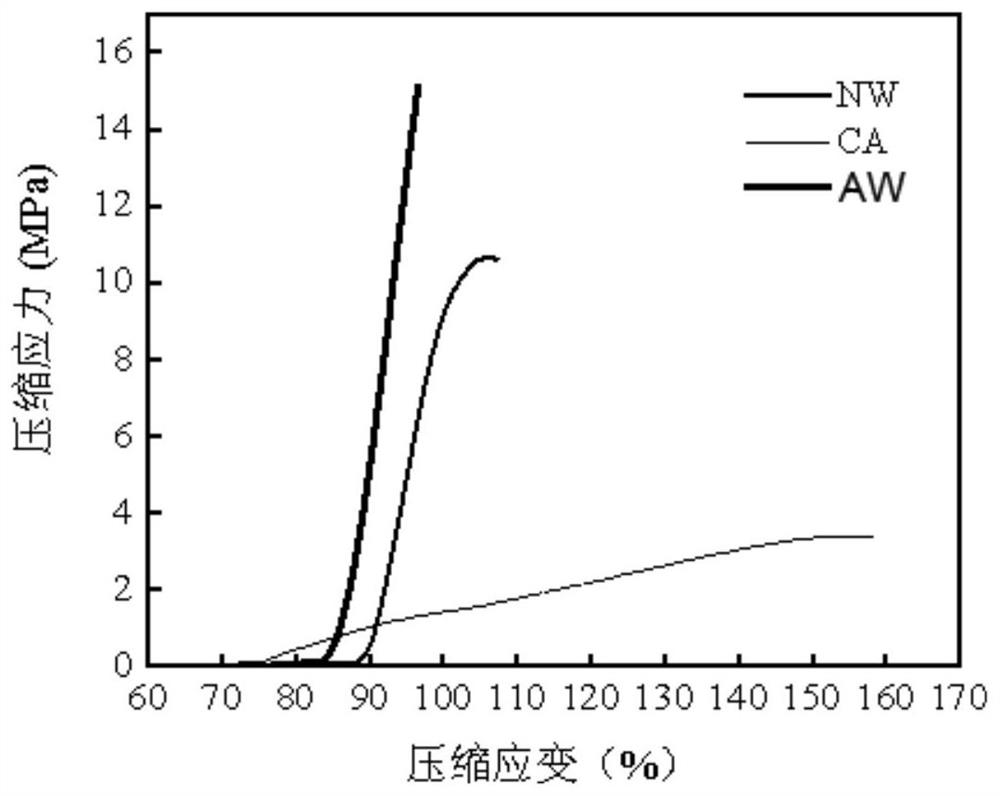

An anisotropic, aerogel technology, applied in the direction of wood impregnation, wood treatment, impregnated wood, etc., to achieve the effects of high strength, increased specific surface energy, and high efficiency heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

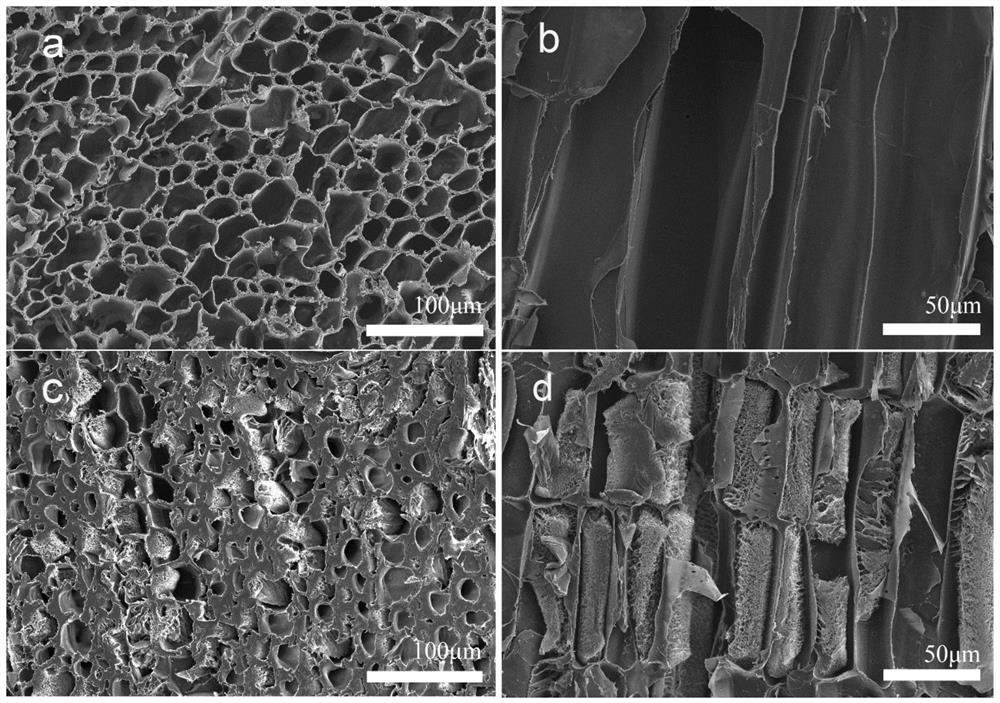

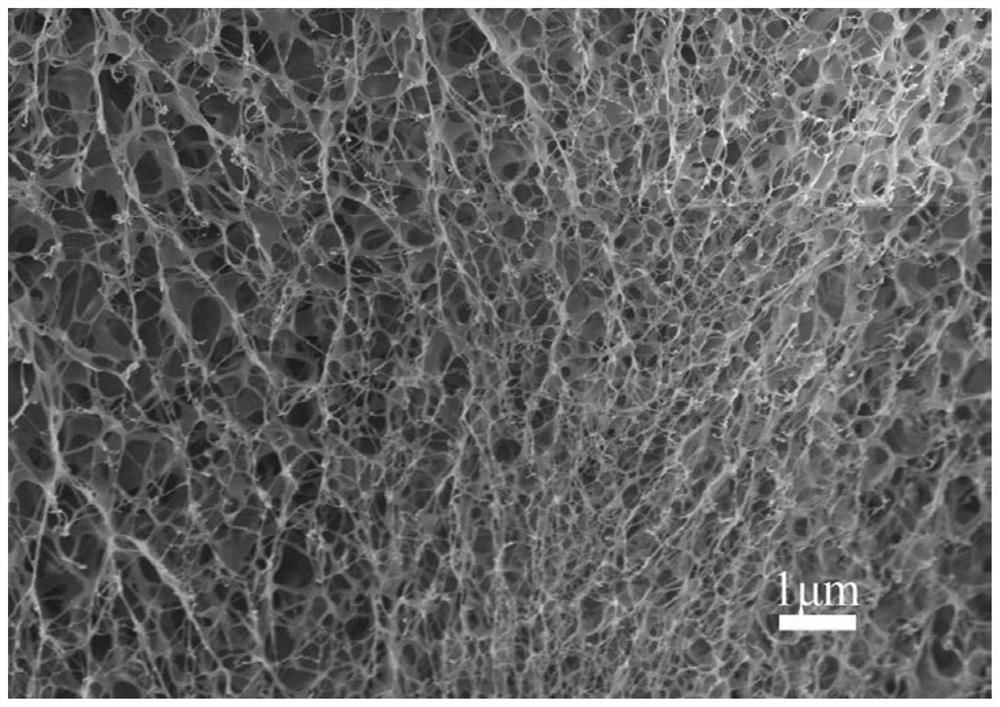

[0056] A preparation method of a high-strength anisotropic aerogel-type wood structure, comprising the following steps and process conditions:

[0057] 1) Preparation of wood: Cut the balsa wood into 40mm×40mm×5mm blocks according to the cross-sectional direction (along the direction of wood growth), and purify it in an ethanol bath at 60°C for 2 hours, and dry it in a vacuum drying oven at 40°C for 2 hours. Pretreatment every day to keep the moisture content less than 15%;

[0058] 2) Wood solvent infiltration: immerse the wood block in 1-methyl-3-propenylimidazole ionic liquid at 60°C;

[0059] 3) Preparation of wood structure containing cellulose sol: the infiltrated wood block is dissolved in the above-mentioned ionic liquid at a temperature of 80 ° C, and the inner wall of the wood cell cavity is partially dissolved in situ by ultrasound, so that the fibers are dissolved and filled. into the cell cavity;

[0060] 4) Preparation of fiber-containing hydrogel wood structur...

Embodiment 2

[0073] A preparation method of a high-strength anisotropic aerogel-type wood structure, comprising the following steps and process conditions:

[0074] 1) Material preparation of wood: cut poplar wood into 30mm×30mm×4mm blocks according to the cross-sectional direction, and pre-process by ultrasonic treatment with ethanol for 1 hour and drying at 40° C. to maintain a moisture content of 5-8wt%;

[0075] 2) Wood solvent infiltration: fully infiltrate the wood block in a DMAC / LiCl (LiCl mass fraction of 8%) mixed solvent at normal temperature and pressure;

[0076] 3) Preparation of wood structure containing cellulose sol: the infiltrated wood block is dissolved at a temperature of 80°C, and the inner wall of the wood cell cavity is partially dissolved in situ by ultrasound, so that the fibers are dissolved and filled into the cell cavity pores;

[0077] 4) Preparation of fiber-containing hydrogel wood structure: the wood sample treated in step 3) is placed in acetone:water=1:1 ...

Embodiment 3

[0081] A preparation method of a high-strength anisotropic aerogel-type wood structure, comprising the following steps and process conditions:

[0082] 1) Preparation of wood: Cut the beech wood into 50mm×40mm×3mm pieces according to the cross-sectional direction, and let it stand for 3-10 hours with acetone:ethanol=1:1, and dry it naturally for pretreatment to keep the moisture content in the 10% or so;

[0083] 2) Wood solvent infiltration: fully infiltrate the wood block in the mixed solvent of NaOH: urea: water=7:12:81 under normal temperature and pressure;

[0084] 3) Preparation of wood structure containing cellulose sol: dissolve the infiltrated wood block at a temperature of -11 °C, and ultrasonically promote the partial dissolution of the inner wall of the wood cell cavity in situ, so that the fibers are dissolved and filled into the cell cavity. ;

[0085] 4) Preparation of fiber-containing hydrogel wood structure: the wood sample treated in step 3) is placed in 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com