Green preparation method for hydroxyl oxime acid rare-earth flotation agents

A flotation reagent and rare earth technology, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, flotation, etc., can solve the problems of environmental protection pressure and governance problems of production enterprises, high industrial production costs, increased production costs, etc., to achieve flotation Excellent selection performance, improve the economic benefits of the enterprise, and reduce the effect of wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

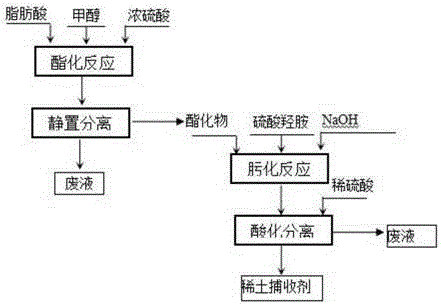

Image

Examples

Embodiment 1

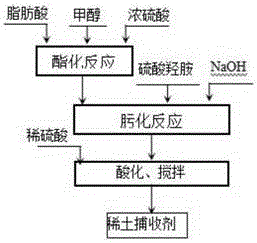

[0040] Process flow chart such as figure 2 shown.

[0041] Will C 5~7 Add 20kg of fatty acid, 10kg of o-hydroxynaphthoic acid and 10kg of methanol into the enamel reaction kettle. After stirring evenly, add 2.8kg of concentrated sulfuric acid. After installing the cooling reflux device, start heating and reflux reaction for 20 hours. After cooling to room temperature, add Add 15% hydroxylamine sulfate aqueous solution of 16.0kg hydroxylamine sulfate to the enamel reaction kettle, add dropwise a 35% sodium hydroxide aqueous solution while stirring, keep the pH value in the reactor not less than 10, control the reaction temperature at 35°C, hydrogen The amount of sodium oxide to be added is 19.0kg. After the dropwise addition, the reaction is continued for 4 hours, and the temperature is kept at 50°C for another 8 hours after the reaction. After the reaction is completed, the reaction product is neutralized with dilute sulfuric acid to a pH value of 5.0-6.0, and stirred After...

Embodiment 2

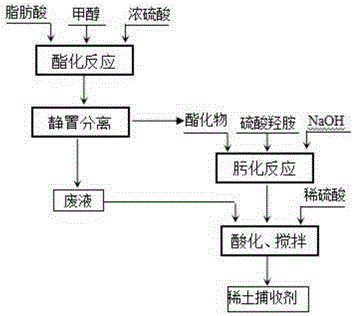

[0043] Process flow chart such as image 3 shown.

[0044] Will C 5~7 Add 20kg of fatty acid, 10kg of o-hydroxynaphthoic acid and 10kg of methanol into the enamel reaction kettle, stir evenly, add 2.8kg of concentrated sulfuric acid, install the cooling reflux device, start heating and reflux reaction for 20 hours, and the product is centrifuged to obtain a paste Mixed carboxylate, the liquid is stored for later use; the paste mixed carboxylate of gained and the 15% hydroxylammonium sulfate aqueous solution containing 16.0kg hydroxylammonium sulfate are added in the enamel reaction kettle, while stirring, the mass fraction is 35% hydrogen Sodium oxide aqueous solution, keep the pH value in the reaction kettle not less than 10, control the reaction temperature at 35°C, add 16.0kg of sodium hydroxide dropwise, react for 4 hours after the dropwise addition, keep warm for 8 hours after the reaction, and the temperature is 50°C ; After the reaction is completed, the waste liquid ...

Embodiment 3

[0046] Except C 5~7 Fatty acid obtains weight and is 50g, and the weight of o-hydroxy naphthoic acid is 30g, and the addition of the vitriol oil is 8g, and reflux time is 30 hours, and the molar number of 15~25% hydroxylamine sulfate aqueous solution is that molar number is C 5~7 Except 0.65 times of fatty acid and o-hydroxy naphthoic acid total molar number, all the other are consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com