Water-jet asymptotic shaping method of sheet

A technology of high-pressure water jetting and sheet metal, applied in the field of mechanical engineering, can solve problems such as difficult to meet production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: It is the processing of the plate in free state.

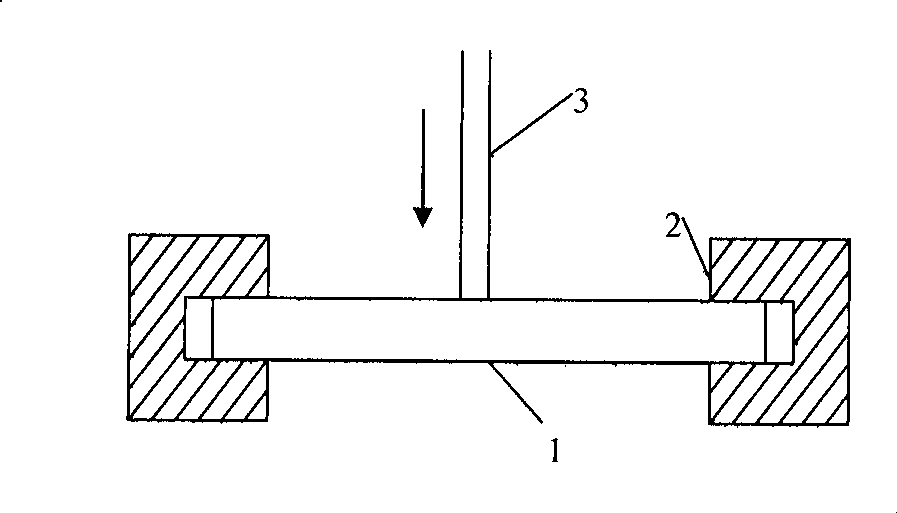

[0012] In this embodiment, a 1.5 mm thick copper plate is used. as attached figure 1 shown. The copper plate 1 is fixed around by the fixing device 2, and the middle is in a suspended state. The copper plate 1 and the fixing device 2 are fed together with the worktable at a certain speed and according to a predetermined path. The high-pressure water jet 3 acts on the surface of the copper plate, and the copper plate is deformed by the pressure of the water jet. The pressure and flow of the water jet can be adjusted to control the deformation of the copper plate perpendicular to the direction of the water jet. Cooperating with the movement of the worktable, the copper plate is processed into the desired shape. The working parameters adopted in this embodiment are: the working pressure of the high-pressure water jet is 35 MPa, the flow rate of the high-pressure water jet is 60 L / min, and the diameter of ...

Embodiment 2

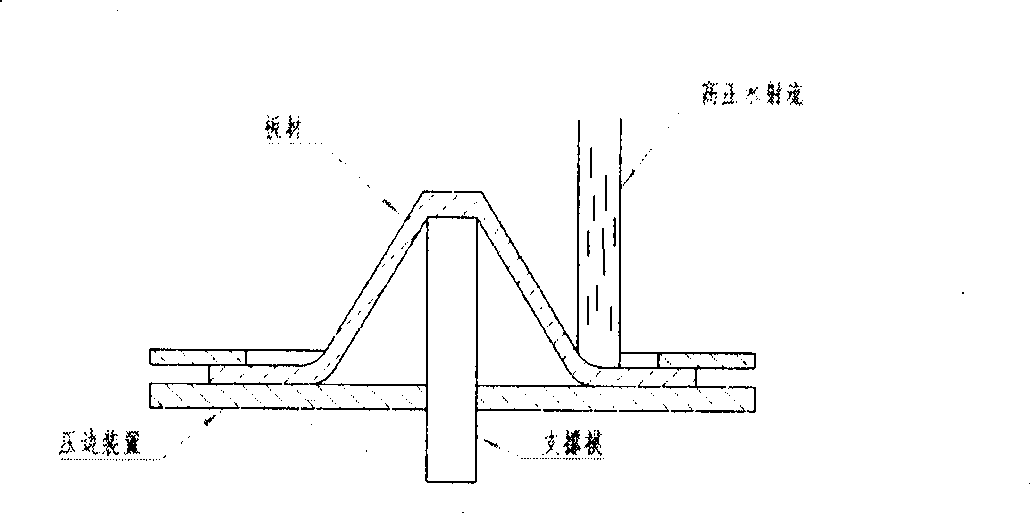

[0013] Embodiment 2: for the processing of the plate when there is a half mold.

[0014] In this embodiment, a 1.0 mm thick steel plate is used. The surroundings of the steel plate are fixed with a blanking device, and the support mold half is placed under the steel plate, and the steel plate and the half-mold follow the workbench to move along the predetermined path at the same time, see the attached image 3 shown. The high-pressure water jet acts on the steel plate, and gradually presses the steel plate to the half-mold until the steel plate is close to the half-mold, and finally, the shape of the half-mold is the shape of the steel plate. The working parameters adopted in this embodiment are: the working pressure of the high-pressure water jet is 40 MPa, the flow rate of the high-pressure water jet is 60 L / min, and the diameter of the nozzle is Φ1.0 mm. See attached parts after processing Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com