Abrasive particle cutting thickness distribution solution method and application method of abrasive particle cutting thickness distribution solution in grinding process design

A technology of grinding amount and abrasive particles, applied in the field of grinding, can solve the problems of difficult optimization and difficult to achieve results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

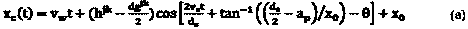

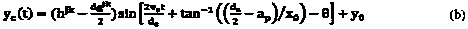

[0053] The following describes in detail the method for solving the abrasive particle cutting thickness distribution in conjunction with the accompanying drawings:

[0054] Adopt grinding wheel parameters: grinding wheel diameter ds=300cm, width 10cm, abrasive grain parameters are expressed by a distribution function, particle size, position and height of the cutting edge are all normal distribution, the distribution parameters are: particle size N (550, 0.25), position N (0.1 , 0.4) and the blade height N (67, 0.15), the grinding amount is: grinding speed vs=78m / s, feed speed vw=15m / min, and grinding depth is 8um.

[0055] Step A. Build a digital grinding wheel: express the abrasive parameters on the surface of the grinding wheel as a matrix {G jk } p×q , P×q means that the matrix {Φ} is a matrix of p rows and q columns, that is, the outer circle of the grinding wheel has p rows and q columns of abrasive grain distribution. In this embodiment, p=9000, q=20; element G jk Represents...

Embodiment 2

[0073] This embodiment details the specific implementation method of applying a method for solving the distribution of abrasive grain cut thickness to the design of the grinding process:

[0074] In this embodiment, the grinding tool is a grinding wheel, and the grinding process is designed with the goal of obtaining a good processed surface quality. The workpiece is 45# steel, and the surface roughness Ra of the machining result is expected to be less than 0.4um. The user has given a wheel diameter of 400mm and a width of 15m. The estimated grinding quantity is: grinding speed vs=100m / s, feed speed vw=10m / min, and grinding depth is 5um. The standard value is set to be less than 10% in the cut thickness distribution error of the two abrasive grains.

[0075] Step 1: Set the target abrasive grain cutting thickness distribution according to the processing result, such as Figure 5 As shown in distribution A.

[0076] Step 2: According to the method for solving the abrasive grain cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com