Energy field assisted intelligent multi-point forming method and system for amorphous alloy parts

An amorphous alloy, multi-point forming technology, applied in computer-aided design, metal processing equipment, instruments, etc., can solve the problems of multiple forming, limited industrial application, easy crystallization and oxidation of amorphous alloys, and achieve coordination. Overall control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

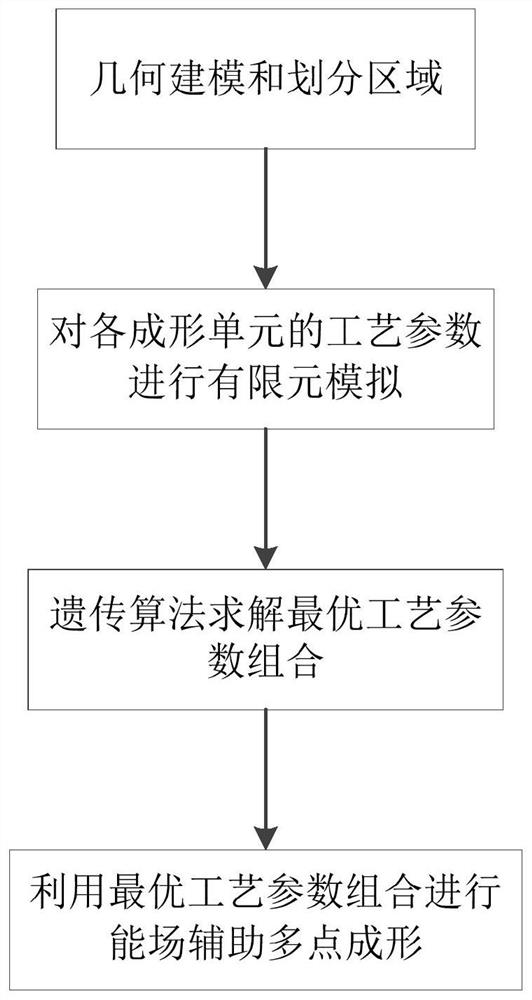

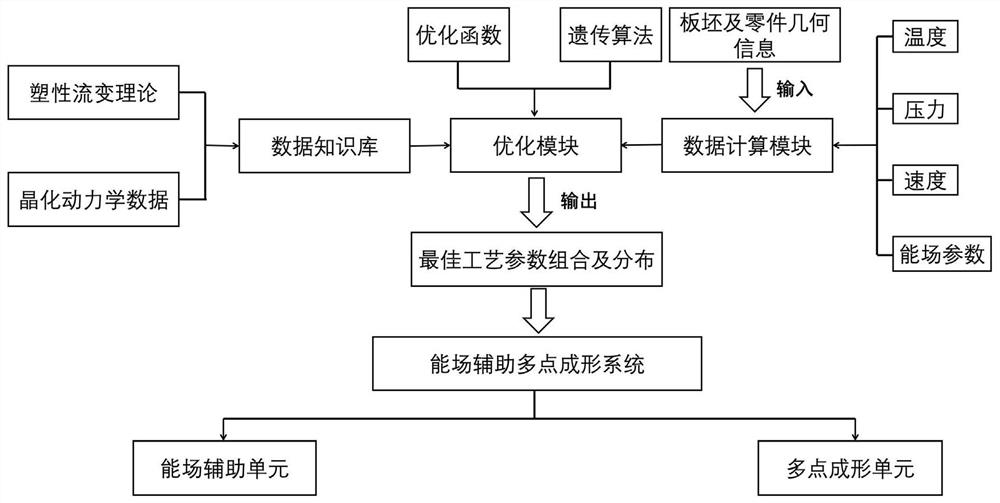

Method used

Image

Examples

Embodiment 1

[0094] The target amorphous alloy part is a typical large three-dimensional curved thin-walled part with local bosses, and the material is Zr 55 Cu 30 Ni 5 al 10 Amorphous alloy, the blank is a slab prepared by continuous casting and rolling technology, with a thickness of 3mm. When the traditional plate is deep-drawn to form a local boss, the boss is prone to deep-drawing cracks due to uneven deformation. Pre-brittleness. Moreover, when the force is applied to the boss, it is a stress concentration area, which requires high comprehensive performance of the material. Traditional forming technology is difficult to achieve the shape-property collaborative manufacturing of target amorphous alloy parts. This embodiment carries out multi-point forming to this part according to the following method:

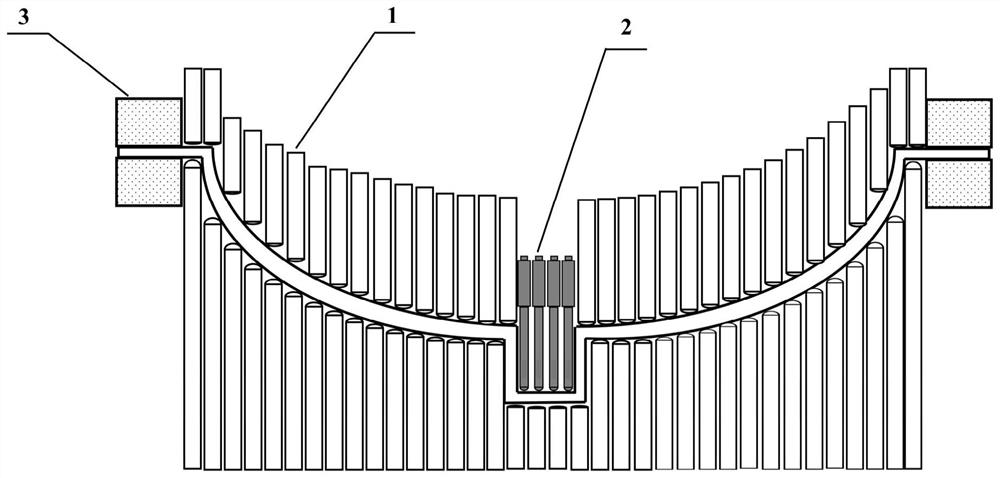

[0095] (1) Digital model extraction and geometric division: perform three-dimensional scanning on the target amorphous alloy part to obtain the shape profile information of the t...

Embodiment 2

[0119] The target amorphous alloy part and material composition are the same as those in Example 1. Figure 5 Shown is a device schematic diagram of a local electromagnetic field-assisted multi-point forming method for amorphous alloy parts based on the present invention, including 1-multi-point forming unit, 8-electromagnetic field-assisted forming unit, 3-flexible edge-holding unit, etc. The forming steps are the same as in Example 1. Image 6 Shown is a schematic diagram of the electromagnetic field assisted forming system, including 9-electromagnetic coil, 10-electromagnetic excitation power supply. According to the energy field-assisted intelligent multi-point forming method of the present invention, a reasonably distributed electromagnetic field and thermal field are constructed inside the part, and the electromagnetic excitation power supply 10 is turned on before forming, and a 60 Hz power frequency alternating current is passed through the electromagnetic coil 9 to ge...

Embodiment 3

[0121] The target amorphous alloy part and material composition are the same as those in Example 1. Figure 7 Shown is a device schematic diagram of a local electric field-assisted multi-point forming method for amorphous alloy parts based on the present invention, including 1-multi-point forming unit, 11-electric field-assisted forming unit, and 3-flexible edge-holding unit. The forming steps are the same as in Example 1. According to the energy field-assisted intelligent multi-point forming method of the present invention, a reasonably distributed current field and thermal field are constructed inside the part, and a pulse current is locally passed to the amorphous alloy slab before forming, the frequency is 80kHz, the amplitude is 60A, and the duty cycle is 20%. The material relies on self-resistance to generate Joule heat, and at the same time, based on the electroplastic effect, the deformation resistance of the amorphous alloy sheet is significantly reduced, realizing r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com