Soybean protein isolate powder as well as preparation method and use thereof

A technology of protein powder and soybean, which is applied in the field of soybean protein isolate powder and its preparation, which can solve the problems of turbidity and opacity of the solution, decrease of hydrophobic force, and influence on product properties, and achieve the effects of improving transparency, enhancing solubility, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

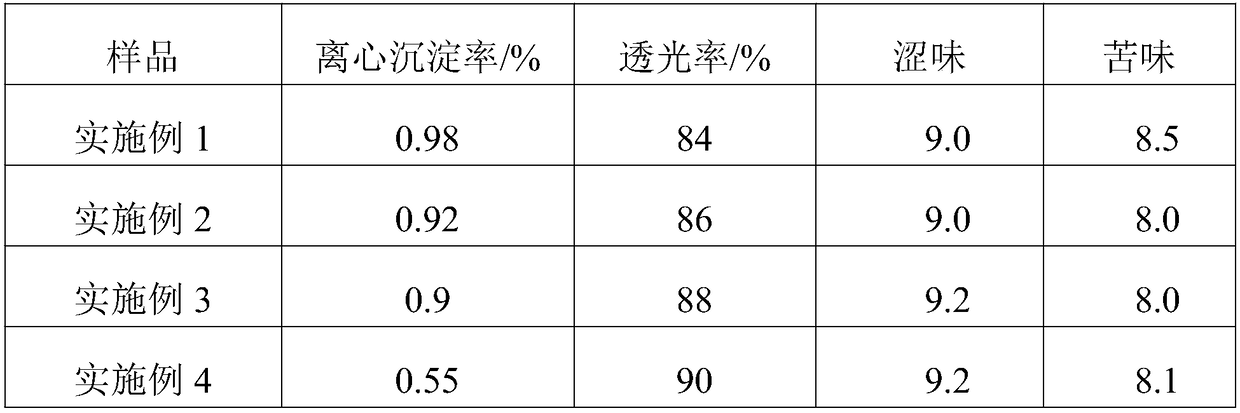

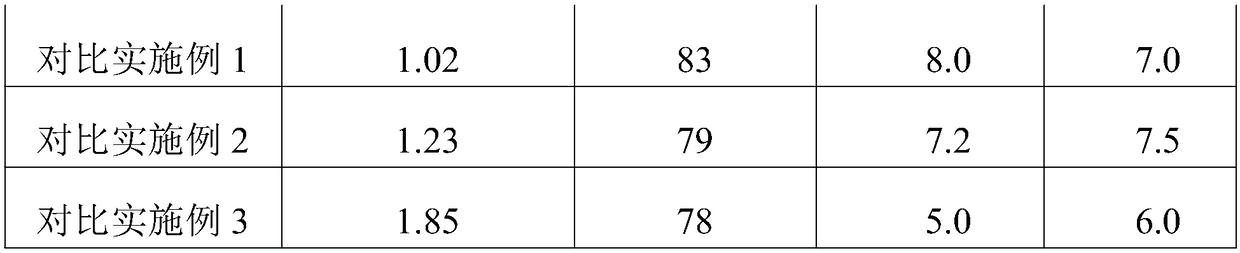

Embodiment 1

[0065] Mix defatted soybean meal with water at a mass ratio of 1:8, stir at room temperature for 1 hour at a medium speed, adjust the pH to 8 with 2mol / L NaOH, and shear the solution at 13000rpm for 3 minutes. Acidase and 0.05‰ laccase were added, reacted at 35°C for 30 minutes, and then centrifuged at 3000rpm for 10 minutes to obtain alkaline-extracted soybean emulsion and soybean dregs. The bean dregs were subjected to shearing treatment, and process water was added at a ratio of 1:5 to the soybean meal for water extraction, and then centrifuged at 3000 rpm for 10 min to obtain water-extracted soy milk and water-extracted bean dregs. The soymilk obtained by the alkali-extracted soymilk and the water-extracted soymilk is mixed to obtain the mixed soymilk. The mixed soybean emulsion was adjusted to pH 4.5 with 2mol / L HCL, centrifuged at 3000rpm for 10min to obtain soybean protein precipitate.

[0066] Prepare a protein solution with a substrate concentration of 9%, then add d...

Embodiment 2

[0068] Mix the defatted soybean meal with water at a mass ratio of 1:9, stir at room temperature for 1 hour, adjust the pH to 9 with 2mol / L NaOH, and shear the solution at 13000rpm for 3 minutes. Acidase and 0.1‰ laccase were added, reacted at 35°C for 30 minutes, and then centrifuged at 3000rpm for 10 minutes to obtain alkaline-extracted soybean emulsion and soybean dregs. The bean dregs were subjected to shearing treatment, and process water was added at a ratio of 1:5 to the soybean meal for water extraction, and then centrifuged at 3000 rpm for 10 min to obtain water-extracted soy milk and water-extracted bean dregs. The soymilk obtained by the alkali-extracted soymilk and the water-extracted soymilk is mixed to obtain the mixed soymilk. The mixed soybean emulsion was adjusted to pH 4.5 with 2mol / L HCL, centrifuged at 3000rpm for 10min to obtain soybean protein precipitate.

[0069] Prepare a protein solution with a substrate concentration of 8%, then add dilute hydrochlo...

Embodiment 3

[0071] Mix the defatted soybean meal with water at a mass ratio of 1:10, stir at room temperature for 1 hour, adjust the pH to 9.5 with 2mol / L NaOH, and shear the solution at 15000rpm for 2 minutes. Acidase and 0.5‰ laccase were added, reacted at 35°C for 30 minutes, and then centrifuged at 3000rpm for 10 minutes to obtain alkaline-extracted soybean emulsion and soybean dregs. The bean dregs were sheared, and process water was added at a ratio of 1:4 to the soybean meal for water extraction, and then centrifuged at 3000 rpm for 10 min to obtain water-extracted soy milk and water-extracted bean dregs. The soymilk obtained by the alkali-extracted soymilk and the water-extracted soymilk is mixed to obtain the mixed soymilk. The mixed soybean emulsion was adjusted to pH 4.5 with 2mol / L HCL, centrifuged at 3000rpm for 10min to obtain soybean protein precipitate.

[0072] Prepare a protein solution with a substrate concentration of 7%, then add dilute hydrochloric acid to adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com