A metal lithium anode with a high specific surface protection layer and a preparation method thereof

A high specific surface area, metal lithium technology, applied in battery electrodes, electrode carriers/current collectors, structural parts, etc., can solve problems such as poor cycle performance, achieve high porosity, simple preparation, and strong industrial applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

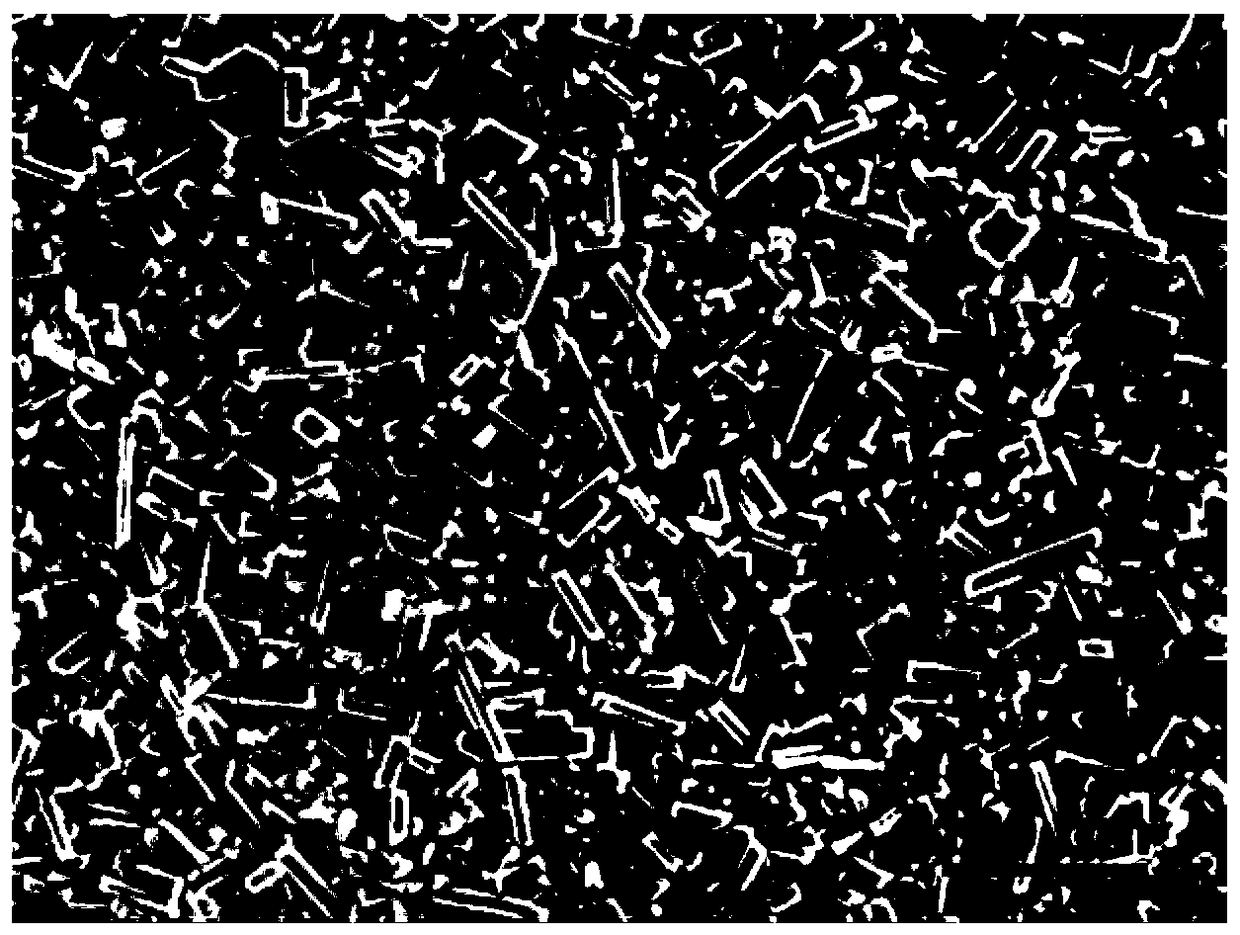

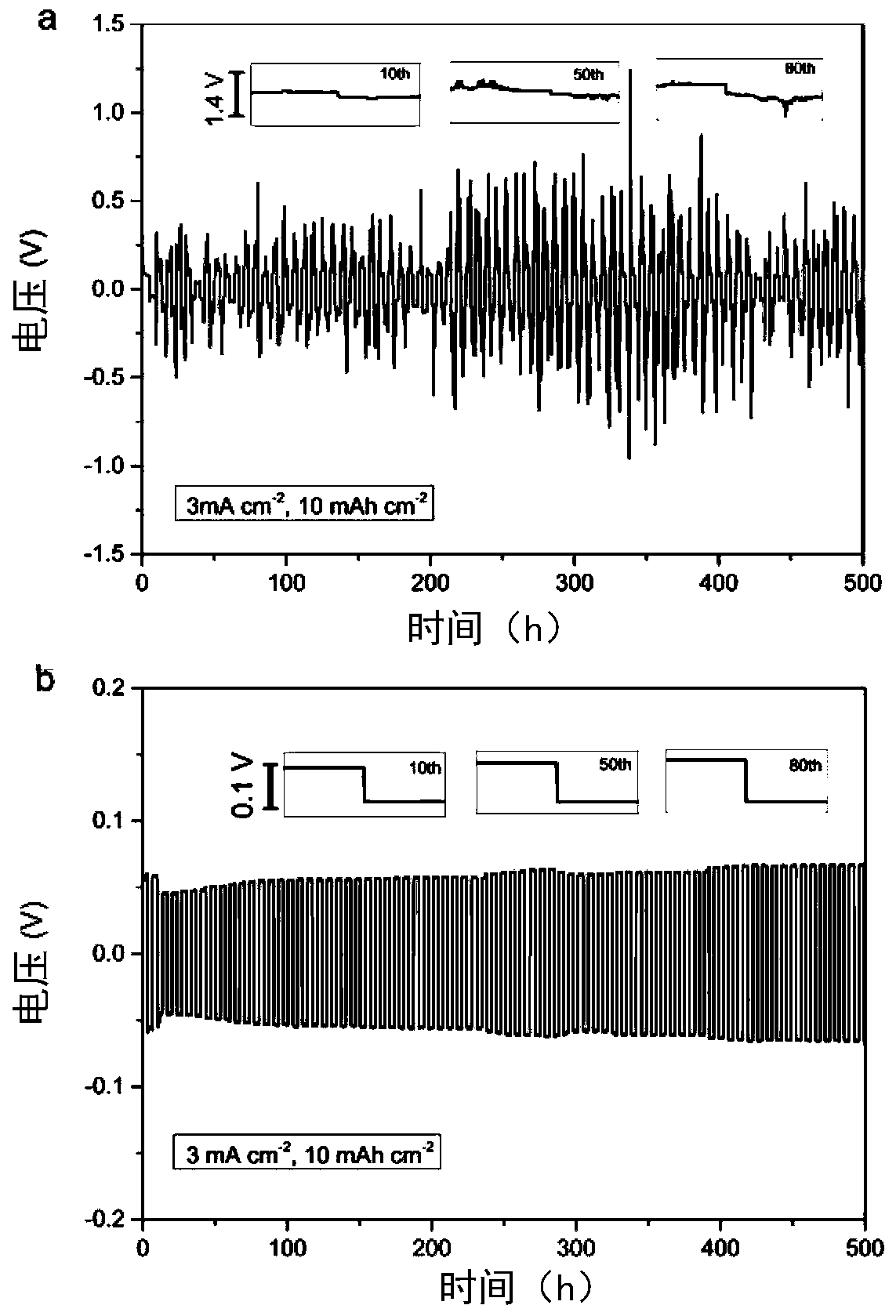

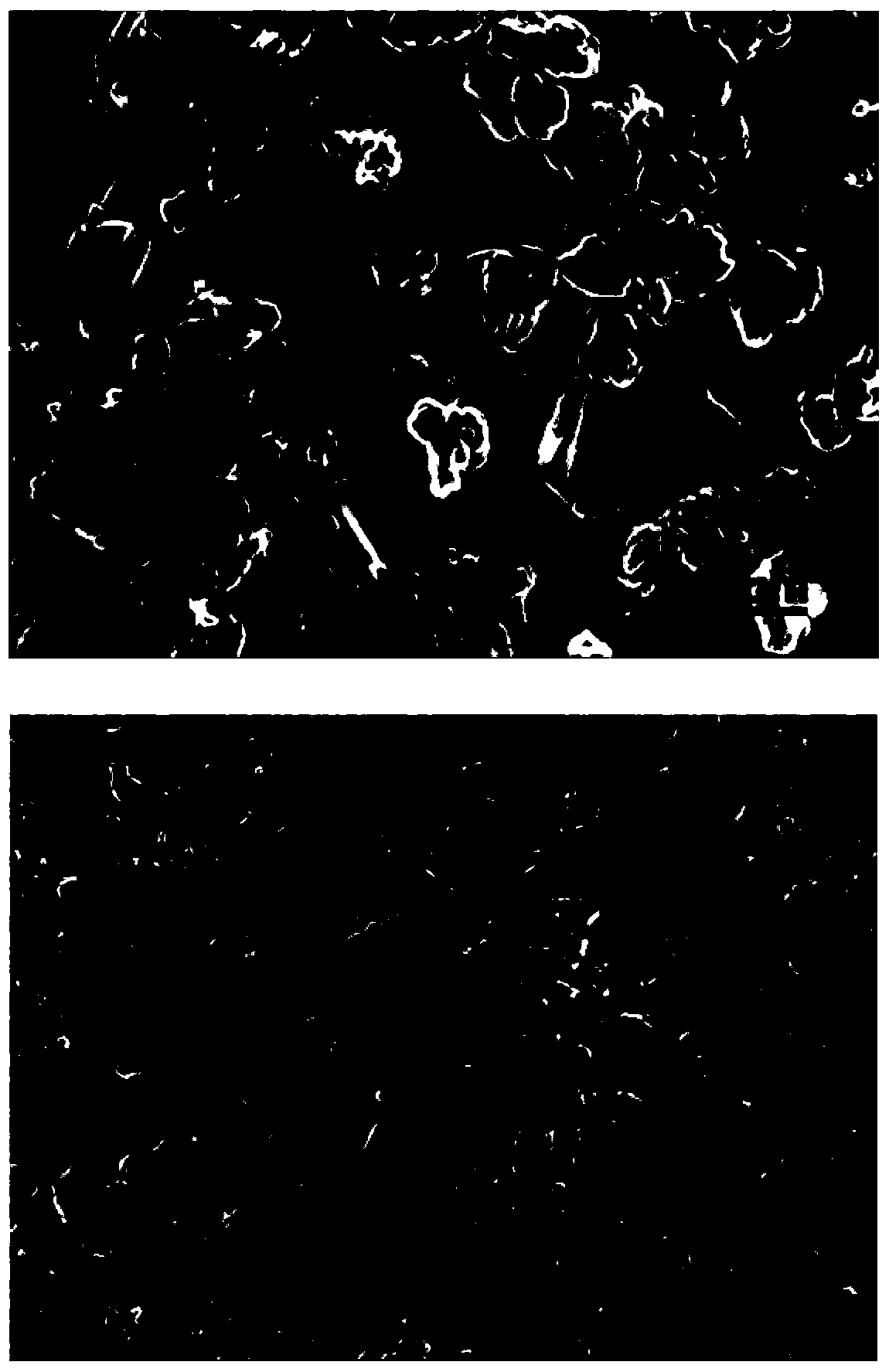

[0036] The carbon nanofibers were dried in an oven at 60° C. for 10 h, and then styrene-butadiene rubber (SBR) was dissolved in a toluene solution to obtain a SBR / toluene solution, so that the mass concentration of the styrene-butadiene rubber was 2%. The dried carbon fiber (1g) is added into SBR / toluene solution (5g) and stirred evenly. In a glove box full of argon, this solution is evenly sprayed on the surface of the lithium metal sheet, and finally the lithium metal sheet obtained is placed in the Dry in an oven at 60°C for 10 h. A metal lithium negative electrode with a carbon fiber film protective layer was obtained, and the thickness of the carbon fiber protective layer was 50 microns. figure 1 shows the schematic diagram of the prepared carbon fiber layer / lithium anode structure, from figure 1 It can be seen that carbon fibers with a diameter of 1-10 microns and a length of 20-100 microns are evenly distributed on the surface of the metal lithium negative electrode. T...

Embodiment 2

[0038] The carbon fibers were dried in an oven at 60° C. for 10 h, and then styrene-butadiene rubber (SBR) was dissolved in a xylene solution to obtain an SBR / xylene solution, so that the mass concentration of the styrene-butadiene rubber was 2%. Add the dried carbon fiber (1g) into the SBR / xylene solution (5g) and stir evenly. In a glove box full of argon, this solution is evenly sprayed on the surface of the metal lithium sheet, and finally the obtained metal lithium sheet Dry in an oven at 60 °C for 10 h. A metal lithium negative electrode with a carbon nanotube protective layer is obtained. The thickness of the carbon nanotube protective layer is 50 microns.

Embodiment 3

[0040] The carbon fiber was dried in an oven at 60° C. for 10 h, and then polyvinylidene fluoride (PVDF) was dissolved in a solution of methylpyrrolidone (NMP) to obtain a PVDF / NMP solution, so that the mass concentration of polyvinylidene fluoride was 2%. Add the dried carbon fiber (1g) into the PVDF / NMP solution (5g) and stir evenly. In a glove box full of argon, this solution is evenly sprayed on the surface of the lithium metal sheet. Finally, the lithium metal sheet obtained is placed in the Dry in an oven at 60°C for 10 h. A metal lithium negative electrode with a carbon fiber protective layer was obtained. The thickness of the carbon fiber protective layer is 50 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com