Phosphate microcapsule flame retardant and preparation method and application thereof

A flame retardant and phosphate technology, applied in the field of flame retardants, can solve problems such as unsuitable for use, achieve the effects of increasing flame retardant durability, convenient and controllable process, and strong industrial practical applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] a) Add 10g of melamine phosphate and 5ml of sodium dodecylsulfonate dispersant to a three-necked flask equipped with stirring and a thermometer, and add 200ml of N'N-dimethylformamide solvent, raise the temperature to 40 ℃, stirring mechanically and ultrasonically for 0.5h, uniformly dispersing melamine phosphate in N'N-dimethylformamide solvent to obtain a dispersion of melamine phosphate;

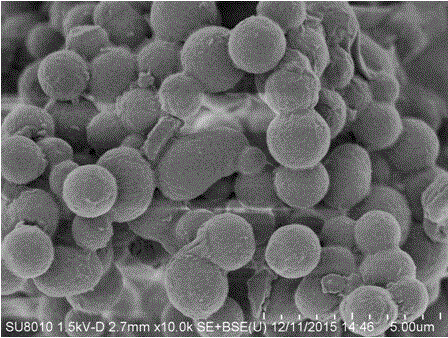

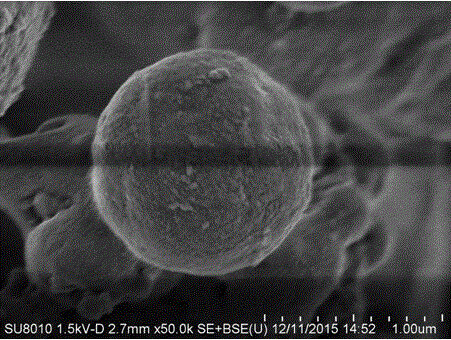

[0034]b) Add hexachlorocyclotriphosphazene and coupling agent γ-aminopropyltriethoxysilane (KH550) to the melamine phosphate dispersion obtained in step a) under mechanical stirring and ultrasonication, and add 3ml acid-binding agent triethylamine, wherein the mol ratio of hexachlorocyclotriphosphazene and coupling agent KH550 is 1:6, and the mol ratio of coupling agent KH550 and acid-binding agent triethylamine is 1:1, in After reacting for 8 hours at 40°C, stop mechanical stirring, cool to room temperature, vacuum filter, and vacuum dry at 90°C for 24 hours to obtain a melamine p...

Embodiment 2

[0036] a) Add 10g of melamine phosphate and 5ml of sodium dodecylsulfonate dispersant to a three-necked flask equipped with stirring and a thermometer, and add 200ml of N'N-dimethylformamide solvent, raise the temperature to 40 ℃, stirring mechanically and ultrasonically for 0.5h, uniformly dispersing melamine phosphate in N'N-dimethylformamide solvent to obtain a dispersion of melamine phosphate;

[0037] b) Add hexachlorocyclotriphosphazene and coupling agent KH550 to the melamine phosphate dispersion obtained in step a) under mechanical stirring and ultrasonication, and add 3ml of acid-binding agent triethylamine at the same time, wherein the hexachlorocyclotriphosphazene The molar ratio of chlorocyclotriphosphazene to coupling agent KH550 is 1:6, the molar ratio of coupling agent KH550 to acid-binding agent triethylamine is 1:1, stop mechanical stirring after reacting at 40°C for 8 hours, and cool to room temperature, vacuum filtration, and vacuum drying at 90°C for 24 hou...

Embodiment 3

[0042] a) Add 10g of melamine phosphate and 5ml of sodium dodecylsulfonate dispersant to a three-necked flask equipped with stirring and a thermometer, and add 200ml of N'N-dimethylformamide solvent, raise the temperature to 40 ℃, stirring mechanically and ultrasonically for 0.5h, uniformly dispersing melamine phosphate in N'N-dimethylformamide solvent to obtain a dispersion of melamine phosphate;

[0043] b) Add hexachlorocyclotriphosphazene and coupling agent KH550 to the melamine phosphate dispersion obtained in step a) under mechanical stirring and ultrasonication, and add 3ml of acid-binding agent triethylamine at the same time, wherein the hexachlorocyclotriphosphazene The molar ratio of chlorocyclotriphosphazene to coupling agent KH550 is 1:6, the molar ratio of coupling agent KH550 to acid-binding agent triethylamine is 1:1, stop mechanical stirring after reacting at 40°C for 8 hours, and cool to room temperature, vacuum filtration, and vacuum drying at 90°C for 24 hou...

PUM

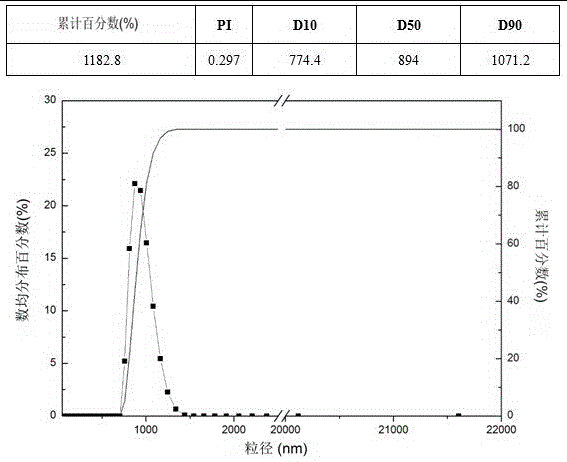

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com