Screened film and preparation method thereof

A manufacturing method and technology of shielding film, which are applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of reducing the shielding effect of the shielding film 1, large contact resistance, and poor conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

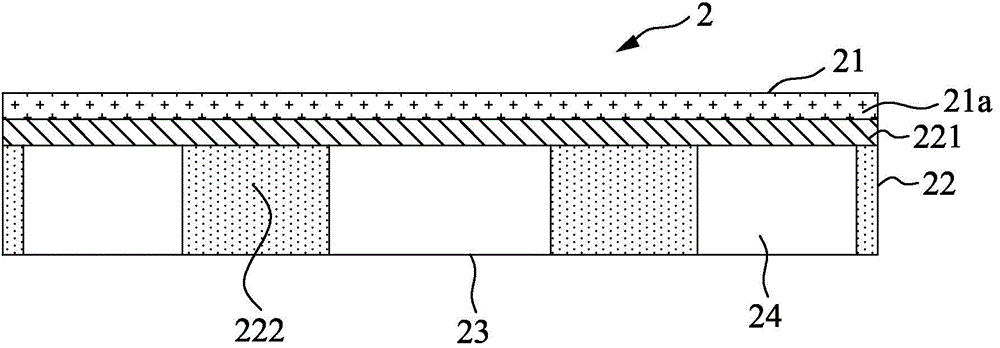

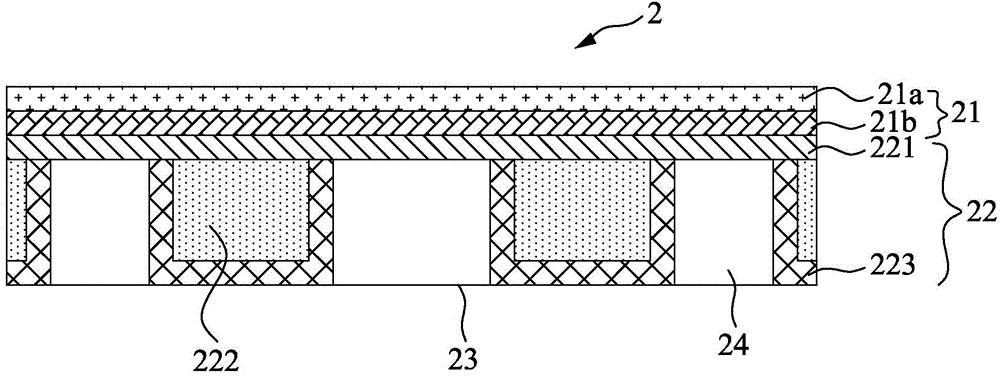

[0063] see Figure 2A , which is the first embodiment of the shielding film 2 structure of the present invention, which includes: an insulating layer 21 , at least one conductive shielding layer 22 and an adhesive layer 24 .

[0064] Such as Figure 2A As shown, the insulating layer 21 may be a separate structure having a first insulating material 21a, and the thickness of the first insulating material 21a is between 5 and 25 microns. The material of the first insulating material 21a can be selected from polyimide (PI-Polyimide), polyethylene terephthalate (PET-Polyethylene Terephthalate), polycarbonate (PC-polycarbonate) or polyphenylsulfone ( PPSU-Polyphenylensulfon) at least one of the materials. In a preferred embodiment, the above-mentioned first insulating material 21a is made of a black material, which has a better effect when manufacturing the shielding film 2 of the present invention.

[0065] read on Figure 2A As shown, a conductive shielding layer 22 is arrange...

no. 4 example

[0106] see Figure 16-17 It is a fourth embodiment of a manufacturing method of a shielding film 2, which includes the following steps:

[0107] (A) providing an insulating layer 21;

[0108] (B) forming a conductive shielding layer 22 on the surface of the insulating layer 21 by evaporation, sputtering or chemical plating;

[0109] (C) Simultaneous die-casting of the above-mentioned insulating layer 21 and the conductive shielding layer 22 with an embossing machine to jointly form a raised metal ground electrode 222;

[0110] (D) An adhesive layer 24 is filled in the filling space 23 on the surface of the conductive shielding layer 22 , and the metal ground electrode 222 is exposed on the surface to form a scattered pattern.

[0111] see Figure 18-19 It is a schematic flow chart of a fifth embodiment of a manufacturing method of a shielding film 2 and a structural diagram thereof, which includes the following steps:

[0112] The step (A) is to first provide a first insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com