Attapulgite-clay-based composite fluorescent material, and preparation method and application thereof

A technology of composite fluorescence and fluorescent dyes, which is applied in the field of attapulgite-based composite fluorescent materials and their preparation, can solve the problems of poor machining performance and solubility of peryleneimide fluorescent materials, unfavorable application of peryleneimide fluorescent materials, and toxic and side effects. and other problems, to achieve the effect of improving machinability, poor solubility, excellent fluorescence properties, and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

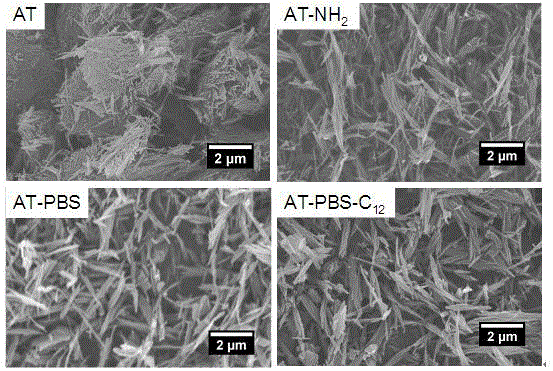

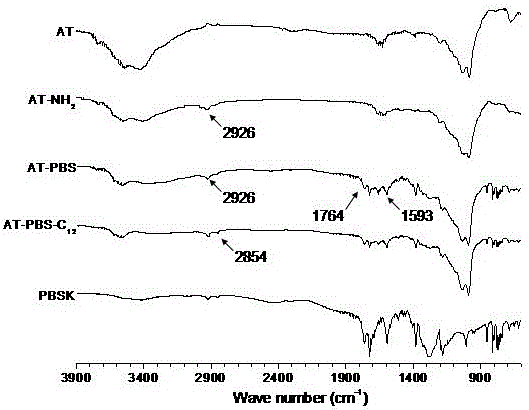

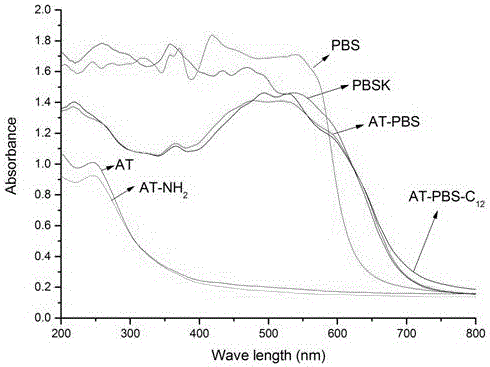

[0046] (1) Put 45 g of attapulgite into 474 g of 0.8 mol / L hydrochloric acid solution, stir evenly, wash with centrifugal water to neutrality, grind into powder after freeze-drying, and ultrasonically disperse 2 g of attapulgite powder after acidification in 98 g of isophthalic acid Gels form in propanol.

[0047] (2) Add 60ml of 2wt.% attapulgite isopropanol gel and 2 mmol of aminopropyltrimethoxysilane into an Erlenmeyer flask, heat at 80°C for 15h, cool, wash by centrifugation, and dry in vacuum at 60°C. The resulting product is recorded as AT-NH 2 .

[0048] (3) Add 0.2g of PBS (perylene-3,4,9,10-tetracarboxylic dianhydride) and 4mL of 0.9 mol / L KOH into the flask, and heat at constant temperature for 1 hour. Then, slowly add 2 mL of 10% HO over 3 hours 3 PO 4 , cooled, centrifuged and washed with water, dried at 70°C, and the resulting product was denoted as PBSK.

[0049] (4) Add 0.1g AT-NH 2 Add it to 10 g of isopropanol, then add 0.1 g of PBSK, put it into a magn...

Embodiment 2

[0053] (1) Put 45 g of attapulgite into 383 g of 1.5 mol / L hydrochloric acid solution, stir evenly, wash with centrifugal water to neutrality, grind into powder after freeze-drying, and ultrasonically disperse 3 g of attapulgite powder after acidification in 97 g of isophthalic acid Gels form in propanol.

[0054] (2) Add 60ml of 3wt.% attapulgite isopropanol gel and 2 mmol of aminopropyltrimethoxysilane into an Erlenmeyer flask, heat at 80°C for 15h, cool, wash by centrifugation, and dry in vacuum at 60°C. The resulting product is recorded as AT-NH 2 .

[0055] (3) Add 0.3g of PBS (perylene-3,4,9,10-tetracarboxylic dianhydride) and 5mL of 0.9 mol / L KOH into the flask, and heat at constant temperature for 1 hour. Next, slowly add 4 mL of 10% HO over 3 hours 3 PO 4 , cooled, centrifuged and washed with water, dried at 70°C, and the resulting product was denoted as PBSK.

[0056] (4) Add 0.1g AT-NH 2 Add it to 10 g of isopropanol, then add 0.08 g of PBSK, put it into a mag...

Embodiment 3

[0060] (1) Put 45g of attapulgite into 420g of 1mol / L hydrochloric acid solution, stir evenly, wash with centrifugal water to neutrality, freeze-dry and grind into powder, ultrasonically disperse 3g of attapulgite powder after acidification in 97g of isopropyl Gels form in alcohol.

[0061] (2) Add 60ml of 3wt.% attapulgite isopropanol gel and 2 mmol of aminopropyltrimethoxysilane into an Erlenmeyer flask, heat at 80°C for 15h, cool, wash by centrifugation, and dry in vacuum at 60°C. The resulting product is recorded as AT-NH 2 .

[0062] (3) Add 0.4g of PBS (perylene-3,4,9,10-tetracarboxylic dianhydride) and 5mL of 0.9 mol / L KOH into the flask, and heat at constant temperature for 1 hour. Next, slowly add 4 mL of 10% HO over 3 hours 3 PO 4 , cooled, centrifuged and washed with water, dried at 70°C, and the resulting product was denoted as PBSK.

[0063] (4) Add 0.1g AT-NH 2 Add it to 10 g of isopropanol, then add 0.12 g of PBSK, put it into a magnetic stirrer, place it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting amount | aaaaa | aaaaa |

| grafting amount | aaaaa | aaaaa |

| grafting amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com