Synthetic method of ciprofibrate

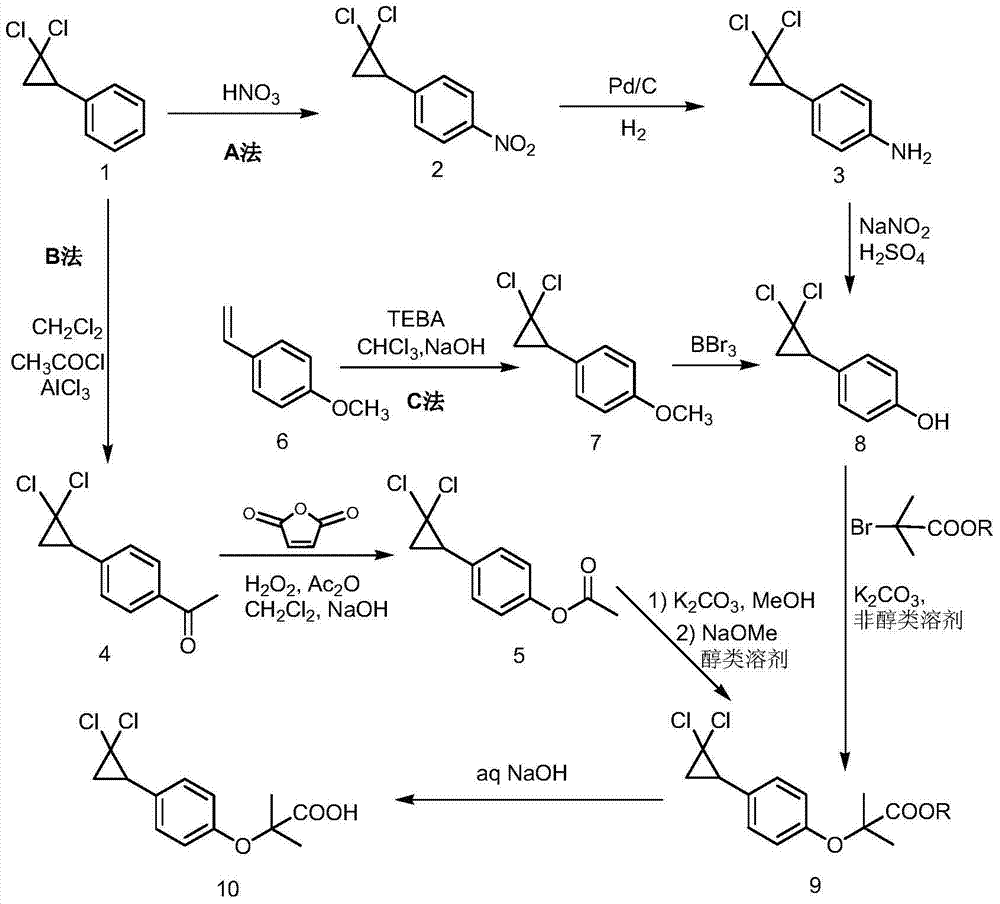

A synthesis method and technology of dichlorocyclopropyl, applied in the synthesis field of cycloprofibrate, can solve the problems of difficult transportation and storage of reagents, easy polymerization, easy decomposition, etc., avoid vicinal by-products, and improve yield and the effect of high purity and H2O2 content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

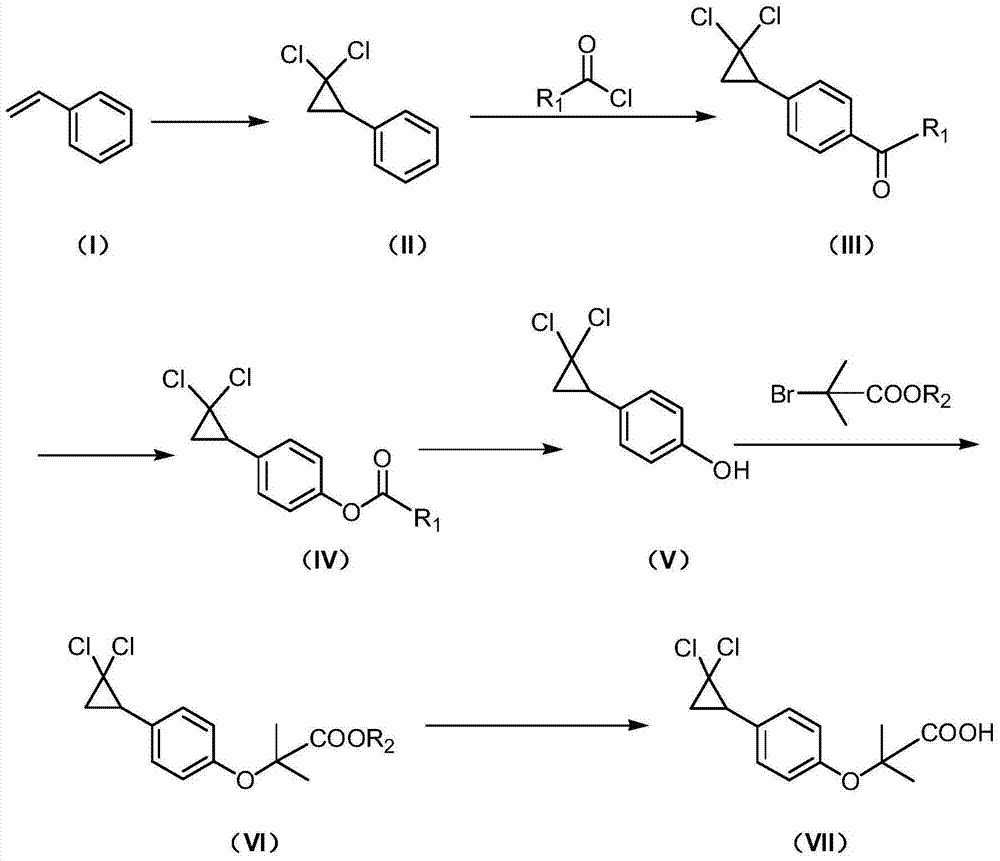

Method used

Image

Examples

Embodiment 1

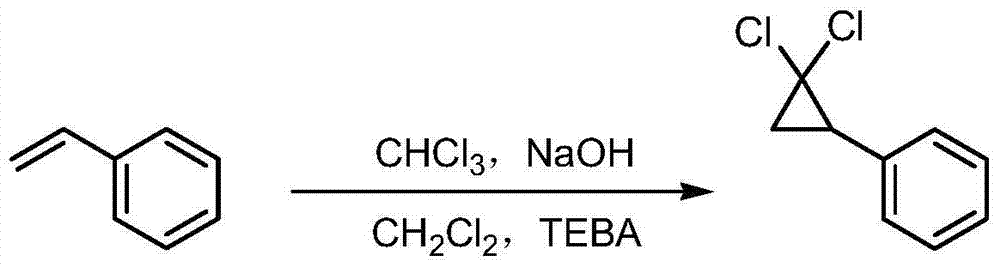

[0042] Embodiment 1: the preparation of 2,2-dichlorocyclopropylbenzene

[0043]

[0044] Add 30g of styrene, 30ml of dichloromethane, 43.5g of chloroform and 1.2g of TEBA (benzyltriethylammonium chloride) into a 250ml four-necked flask. Raise the temperature to reflux, add dropwise lye (28.5g NaOH + 28.5ml water), and reflux for 8 hours. Cool to room temperature, add 60ml of water, stir for 10 minutes, let stand to separate layers, extract the water layer with petroleum ether, combine the organic layers, dry over anhydrous sodium sulfate, filter, and distill the filtrate under high vacuum with an oil pump, slowly heat up to distillate After stabilization, control the temperature at about 95-100°C for distillation to obtain a colorless liquid. Yield: 88.6%; HPLC purity: 99.2%. The HPLC peak time of the product is consistent with that of the commercial standard sample (purchased from Energy Chemical).

Embodiment 2

[0045] Example 2: Preparation of 1-[4-(2,2-dichlorocyclopropyl)phenyl]-1-hexanone

[0046]

[0047] Add 210ml of dichloromethane, 60g of AlCl to a dry 500ml four-neck flask 3 , control the temperature at 20°C, slowly add 75.4g of n-hexanoyl chloride dropwise under stirring, control the temperature below 30°C, continue stirring until AlCl 3 completely dissolved. Cool to 20-25°C, slowly add 70g of 2,2-dichlorocyclopropylbenzene dropwise, raise the temperature to 30-35°C after the dropwise addition, and keep the reaction for 3 hours. After the reaction, the reaction solution was added dropwise to 370 g of ice water, the organic phase was separated, washed with water, washed with saturated brine, dried over anhydrous sodium sulfate, filtered, and concentrated under reduced pressure to obtain 1-[4-(2,2-dichlorocyclo Propyl)phenyl]-1-hexanone. Yield: 98%.

[0048] end product from 1 H-NMR, mass spectrometry and HPLC characterization.

[0049] HPLC purity: 98.3%, the content...

Embodiment 3

[0054] Embodiment 3: Preparation of 4-(2,2-dichlorocyclopropyl)phenol

[0055]

[0056] Add 520ml of acetic acid to a 1000ml four-neck flask, cool to 10-15°C, add 138g of carbamide peroxide (UHP), add 118g of maleic anhydride, and keep stirring at 15-20°C for 3 hours. Raise the temperature to 35-40°C, add 86.1g of 1-[4-(2,2-dichlorocyclopropyl)phenyl]-1-hexanone dropwise, raise the temperature to 45-50°C after dropping, and keep the reaction for 5 hours. Cool to room temperature, wash with water, dry over anhydrous sodium sulfate, filter, and concentrate under reduced pressure to obtain a brown-yellow liquid.

[0057] Add 100ml of methanol and 2.6g of potassium carbonate, heat up to 35-40°C with stirring, keep the reaction for 4 hours, and concentrate under reduced pressure to remove methanol. The concentrate was dissolved in dichloromethane, washed with water, adjusted to pH 9-10 with dilute lye, the aqueous layer was separated, acidified with dilute hydrochloric acid to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com