Fe3O4/Fe<0>/coke biomimetic catalyst capable of degrading POPs (persistent organic pollutants) and preparation method of catalyst

A catalyst and coke technology, which is applied in the field of Fe3O4/Fe0/coke imitation enzyme catalyst for degrading POPs and its preparation, can solve the problems of easy agglomeration of the catalyst, high cost of the carrier, and difficulty in practical application, so as to achieve easy availability of raw materials and increase removal efficiency , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

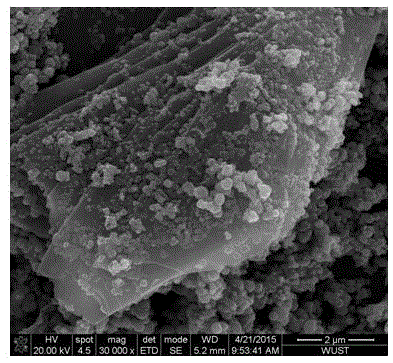

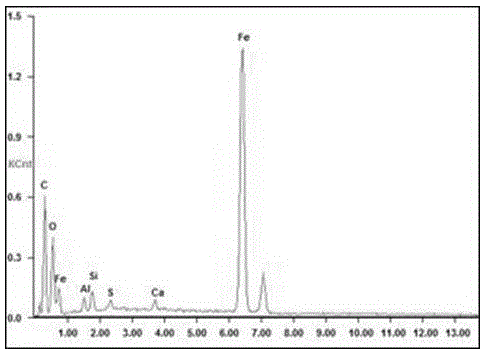

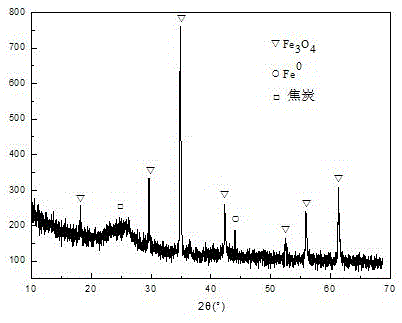

Image

Examples

Embodiment 1

[0034] A kind of Fe that degrades POPs 3 o 4 / Fe 0 Coke imitation enzyme catalyst and preparation method thereof. The concrete steps of this embodiment are:

[0035] Step 1. Press FeSO 4 ·7H 2 The mass ratio of O: coke: deoxygenated and deionized water is 1: (0.2~0.3): (40~60), FeSO 4 ·7H 2 O. Mix coke and deoxygenated deionized water evenly, place in a reaction kettle, and stir for 20-30min under the conditions of 25-30°C and 800-1200r / min to obtain a suspension.

[0036] Step 2. Press NaBH 4 The mass ratio of solution:suspension is 1:(40~60), NaBH 4 Add the solution into the suspension at a constant speed, and the adding time is 40~60min. Then stir at 25-30°C and 1500-2000r / min for 30-60min, then place the stirred solution in the magnetic field for 5-15min, and separate after standing to obtain solid product Ⅰ. The solid product I was washed alternately with deoxygenated deionized water and absolute ethanol until neutral, and finally dried in a vacuum oven at 65-85...

Embodiment 2

[0043] A kind of Fe that degrades POPs 3 o 4 / Fe 0 Coke imitation enzyme catalyst and preparation method thereof. The concrete steps of this embodiment are:

[0044] Step 1. Press FeSO 4 ·7H 2 The mass ratio of O: coke: deoxygenated and deionized water is 1: (0.3~0.4): (60~70), FeSO 4 ·7H 2 O. Mix coke and deoxygenated deionized water evenly, place in a reaction kettle, and stir for 20-30min under the conditions of 25-30°C and 800-1200r / min to obtain a suspension.

[0045] Step 2. Press NaBH 4 The mass ratio of solution:suspension is 1:(60~70), NaBH 4 Add the solution into the suspension at a constant speed, and the adding time is 40~60min. Then stir at 25-30°C and 1500-2000r / min for 30-60min, then place the stirred solution in the magnetic field for 5-15min, and separate after standing to obtain solid product Ⅰ. The solid product I was washed alternately with deoxygenated deionized water and absolute ethanol until neutral, and finally dried in a vacuum oven at 65-85...

Embodiment 3

[0052] A kind of Fe that degrades POPs 3 o 4 / Fe 0 Coke imitation enzyme catalyst and preparation method thereof. The concrete steps of this embodiment are:

[0053] Step 1. Press FeSO 4 ·7H 2 The mass ratio of O: coke: deoxygenated and deionized water is 1: (0.4~0.5): (70~80), FeSO 4 ·7H 2 O. Mix coke and deoxygenated deionized water evenly, place in a reaction kettle, and stir for 20-30min under the conditions of 25-30°C and 800-1200r / min to obtain a suspension.

[0054] Step 2. Press NaBH 4 The mass ratio of solution:suspension is 1:(70~80), NaBH 4 Add the solution into the suspension at a constant speed, and the adding time is 40~60min. Then stir at 25-30°C and 1500-2000r / min for 30-60min, then place the stirred solution in the magnetic field for 5-15min, and separate after standing to obtain solid product Ⅰ. The solid product I was washed alternately with deoxygenated deionized water and absolute ethanol until neutral, and finally dried in a vacuum oven at 65-85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com