A Permanent Magnet Induction High Gradient Disk Drive

A magnetic induction and inductive technology, applied in the field of coal separation, can solve problems such as weak recovery capacity, low magnetic field strength, and difficult unloading, and achieve the effects of strong recovery capacity, improved recovery rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

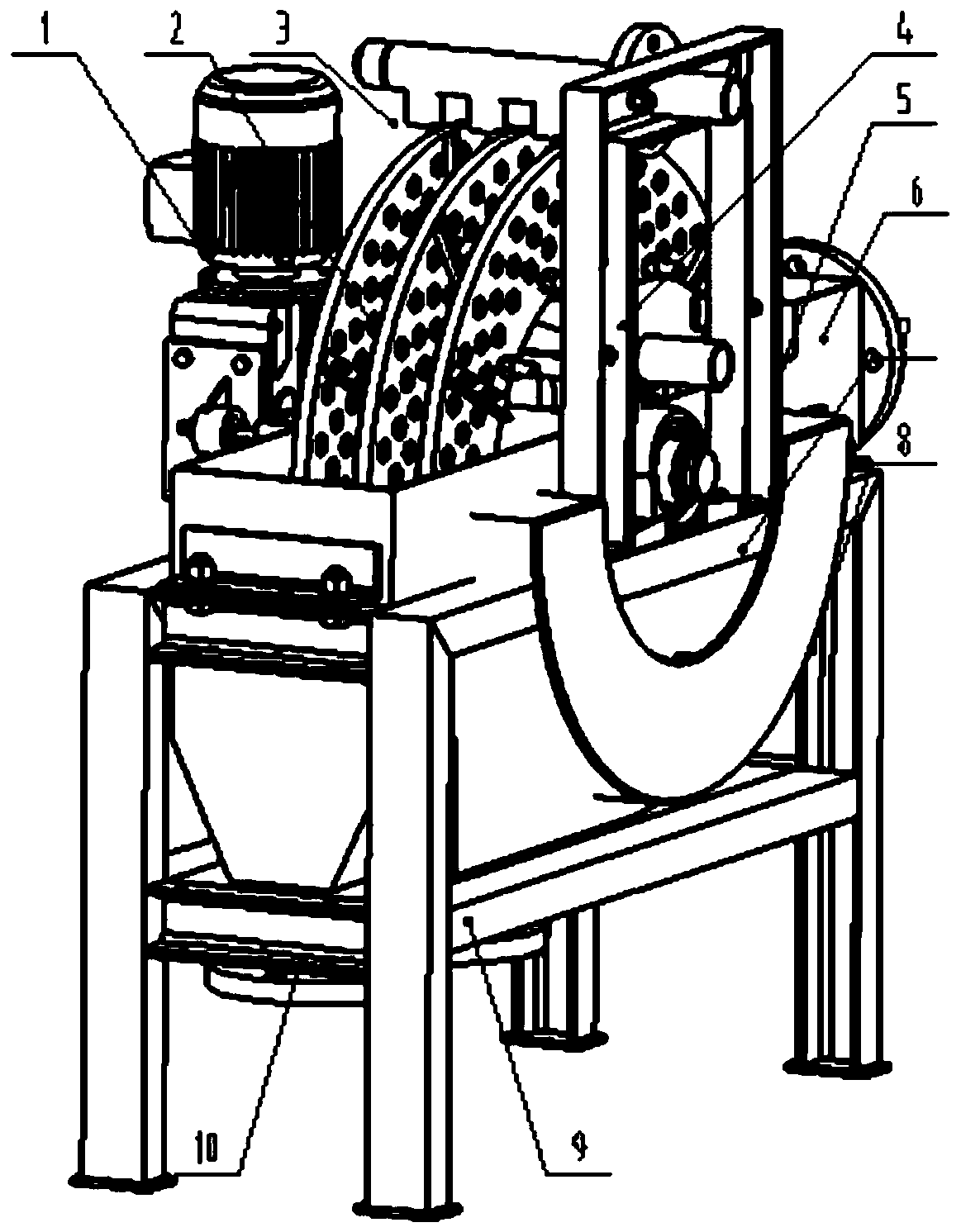

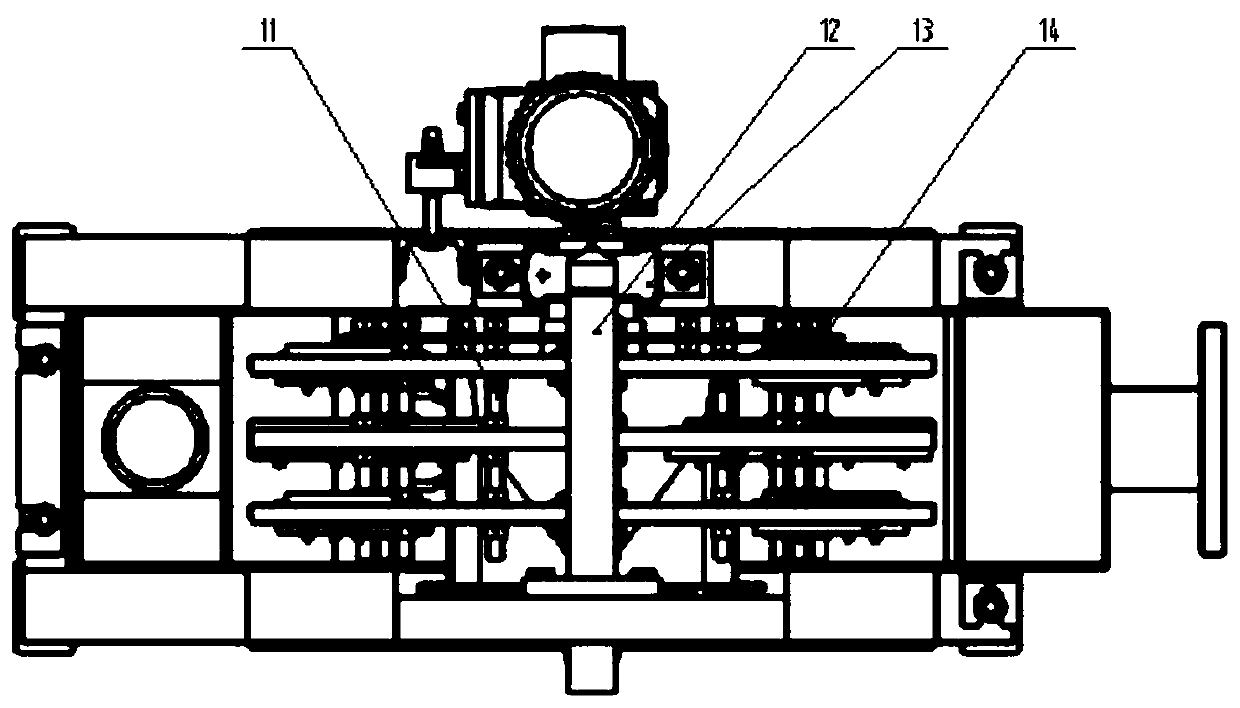

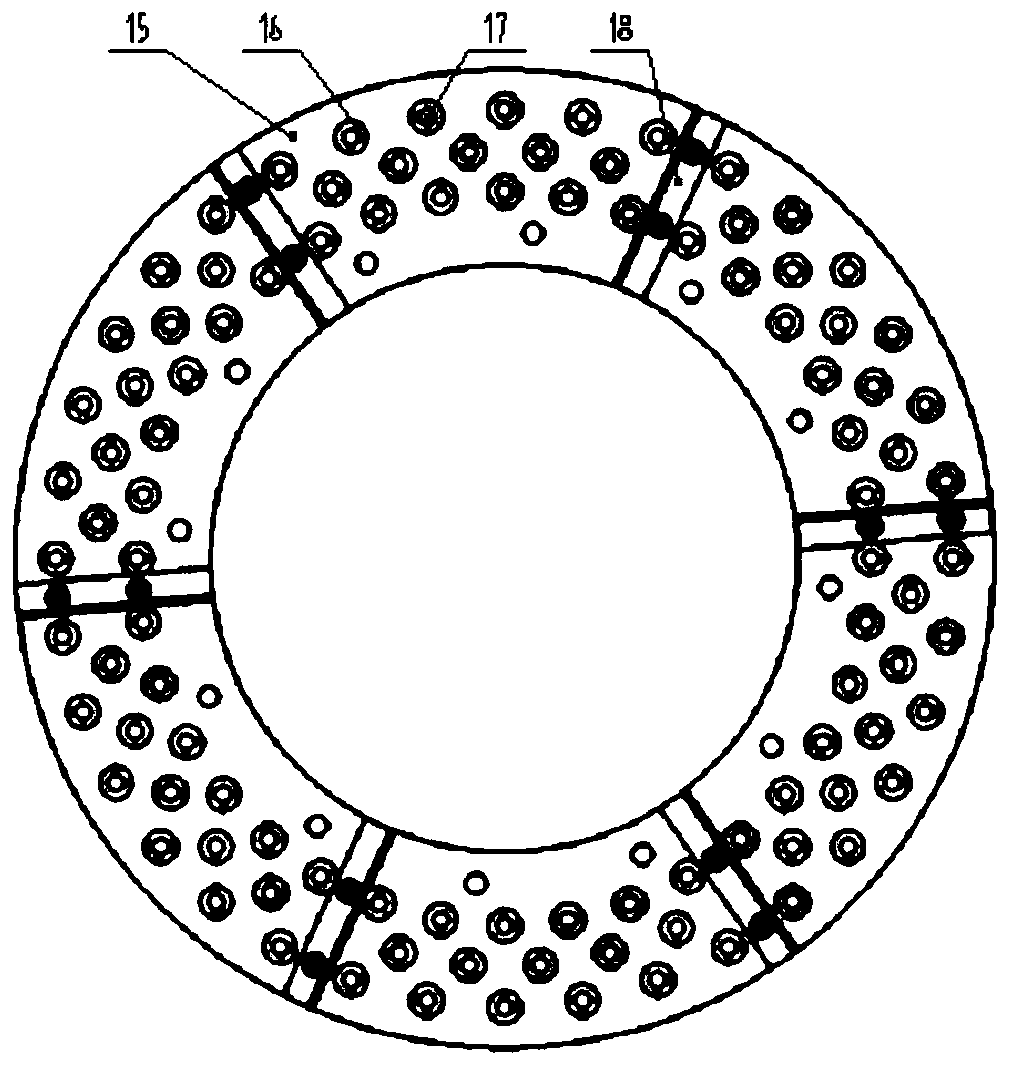

[0045]A permanent magnetic induction type high-gradient disk machine, the power of the drive motor (1) is selected to be 0.37Kw, the diameter of the induction disk (2) is 60cm, the thickness is 5cm, and the number of disks is 6 disks. Background The strong magnetic system (20) is composed of superimposed and combined NdFeB rectangular magnetic blocks with a length*width*height of 50*50*25mm. The inductive disk (2) is 5cm away from the horizontal distance of the sorting tank, the material of the inductive disk chassis (15) is selected as austenitic stainless steel, the ring medium (16) is made of ferritic stainless steel, and the medium core (17) is Austenitic stainless steel with a background magnetic field strength of 1500GS. Such as Figure 5 It can be seen that the distribution of magnetic field strength is that the ring medium of the lower half of the disk is strong, reaching 3000GS; the ring medium of the upper half of the disk is weak, 0GS, which is convenient for unloa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com