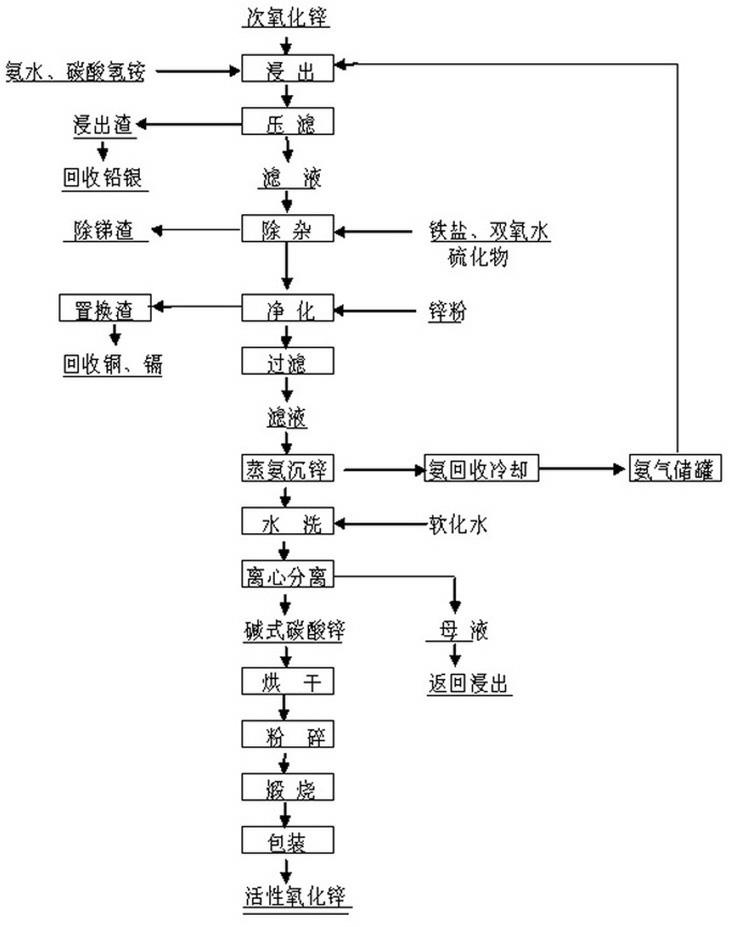

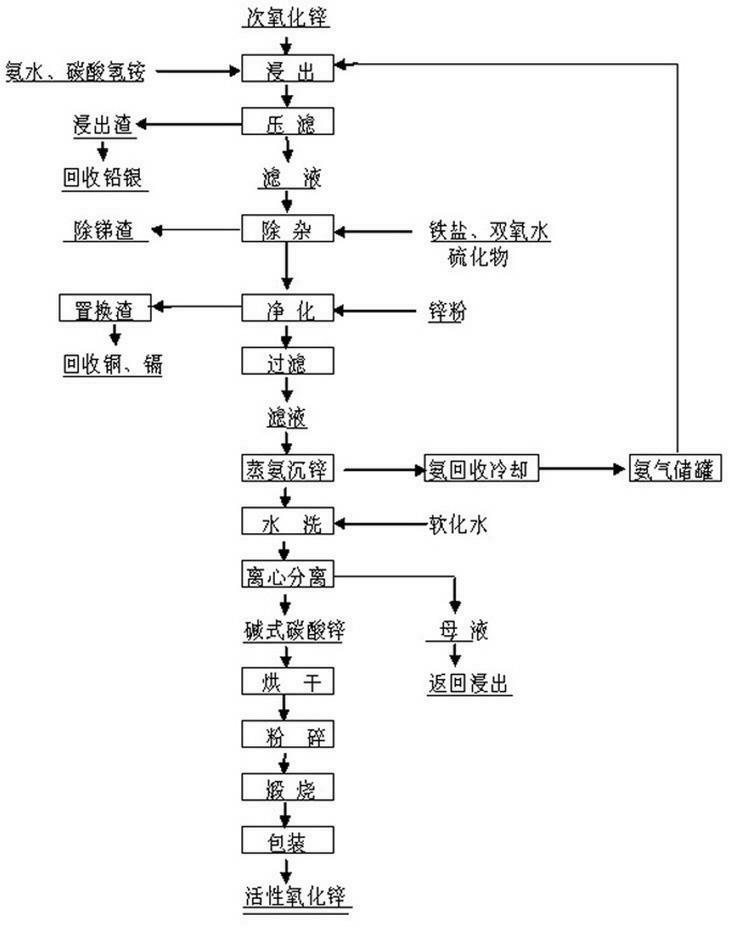

Method for preparing activated zinc oxide by utilizing high-arsenic secondary zinc oxide resource ammonia-ammonium process

A technology of active zinc oxide and sub-zinc oxide, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve problems such as weakness and lack of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061]First configure ammonia-containing water: ammonium bicarbonate = 2.5:1 (molar ratio), leaching agent 1L with a total molar concentration of free ammonia of 8 mol, weigh 250 g of powdered zinc suboxide soot sample, and liquid-solid ratio = 4:1. React at a temperature of ℃-70℃ for 0.5 hours and then filter, add the washing solution to make the volume of the leaching solution the same as that of the leaching agent, the leaching rate of zinc is 93.5%, the composition of the leaching solution (g / L): Zn 107.68; Pb 0.53; Cu 0.036; Cd 0.35; As 1.67; Sb 0.6. Then the leaching liquid is purified and removed. According to the amount of As and Sb, an appropriate amount of hydrogen peroxide and iron salt are added successively to remove impurities and sulfide is added 0.5h before the end of the reaction for secondary removal of impurities; after filtration, according to Cu, 1.2 to 4 times the theoretical amount of zinc powder required for Pb and Cd is added to the zinc powder, and tw...

Embodiment 2

[0064] Prepare ammonia-containing water first: ammonium bicarbonate = 5:1 (molar ratio), 1L of leaching agent with a total molar concentration of free ammonia of 10mol, weigh 200g of powdered zinc suboxide soot sample, and liquid-solid ratio = 2:1, at 30 React at a temperature of ℃-50℃ for 2.0 hours, then filter, add washing liquid to make the leachate volume equal to that of the leaching agent, zinc leaching rate is 90.3%, leachate composition (g / L): Zn 89.25; Pb 0.16; Cu 0.01; Cd 0.25; As 0.87; Sb 0.25. Impurity removal: 30% H is used at the beginning of impurity removal 2 o 2 Carry out pre-oxidation, then slowly add ferrous salt and H 2 o 2 Perform oxidation adsorption to precipitate impurities such as arsenic and antimony, and add sulfide to separate heavy metal ions 30 minutes before the end of the reaction; during the reaction, H 2 o 2 The addition amount is 1~10ml / L, the addition amount of ferrous salt is 0.5~10g / L, the addition amount of sulfide is 0.5~10g / L, the ...

Embodiment 3

[0067] First configure ammonia-containing water: ammonium bicarbonate = 1:1 (molar ratio), 1L of leaching agent with a total molar concentration of free ammonia of 10mol, weigh 100g of powdered zinc suboxide soot sample, and liquid-solid ratio = 10:1. React at a temperature of ℃-85℃ for 4.0 hours, then filter, add the washing liquid to make the volume of the leachate the same as that of the leaching agent, the zinc leaching rate is 92.1%, the composition of the leachate (g / L): Zn 49.25; Pb 0.09; Cu 0.02; Cd 0.11; As 0.35; Sb 0.12. Then the leaching liquid is purified and removed. According to the amount of As and Sb, an appropriate amount of hydrogen peroxide and iron salt are added successively to remove impurities and sulfide is added 0.5h before the end of the reaction for secondary removal of impurities; after filtration, according to Cu, Add zinc powder 20 to 30 times the theoretical amount of zinc powder required for Pb and Cd, and carry out two countercurrent purificati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com