Preparation method of super-hydrophobic natural sponge

A super-hydrophobic and sponge-based technology, applied in separation methods, grease/oily substance/suspton removal devices, liquid separation, etc., can solve the problems of low processing efficiency and easy repetition of pollution, avoiding modification of binders, preparation The process is simple and effective, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

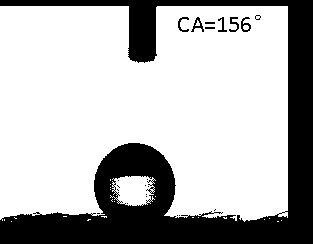

[0025] The natural sponge was ultrasonically cleaned three times with ultrapure water and 75% ethanol, and the stains and residues on the surface of the sponge were removed, and then dried in an oven at 60 °C for use. The resulting sponge was immersed in 50 mL of ethanol, and 1 g of Zn(NO 3 ) 2 •6H 2 Compound O was added to the above mixture, and stirred in a constant temperature water bath at 60 °C for 8 h. The resulting sponge was separated from the mixture and washed twice with ethanol. Weigh 0.25 g of 2-methylimidazole into 50 mL of ethanol solution, disperse the obtained sponge in the above mixture, and stir in a constant temperature water bath at 60 °C for 8 h. The obtained sponge was separated from the mixture, washed twice with ethanol, and dried in an oven at 60 °C to obtain a superhydrophobic natural sponge.

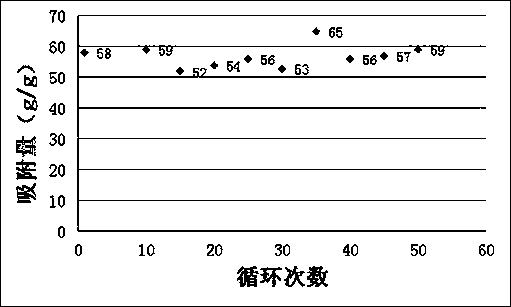

[0026] In order to evaluate the absorption capacity of superhydrophobic natural sponge, n-decane, ethylbenzene, 1,2-dichlorobenzene, ethyl chloride, chloro...

Embodiment 2

[0029] The natural sponge was ultrasonically cleaned twice with ultrapure water and 75% ethanol, and the stains and residues on the surface of the sponge were removed, and then dried in an oven at 80 °C for use. The resulting sponge was immersed in 50 mL of ethanol, and 3 g of Zn(NO 3 ) 2 •6H 2 Compound O was added to the above mixture, and stirred in a constant temperature water bath at 40 °C for 16 h. The resulting sponge was separated from the mixture and washed 3 times with ethanol. Weigh 0.75 g of 2-methylimidazole and place it in 50 mL of ethanol solution, disperse the obtained sponge in the above mixture, and stir in a constant temperature water bath at 40 °C for 16 h. The obtained sponge was separated from the mixture, washed three times with ethanol, and dried in an oven at 80 °C to obtain a superhydrophobic natural sponge.

[0030]In order to evaluate the absorption capacity of superhydrophobic natural sponge, n-decane, ethylbenzene, 1,2-dichlorobenzene, chloroet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com