Manufacturing method of metal plate for power generating boiler supporting beam

A manufacturing method and technology for power generation boilers, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low recycling rate, poor debris collection effect, hindering normal processing, etc., and achieve recycling rate High, good debris collection effect, beneficial to the collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

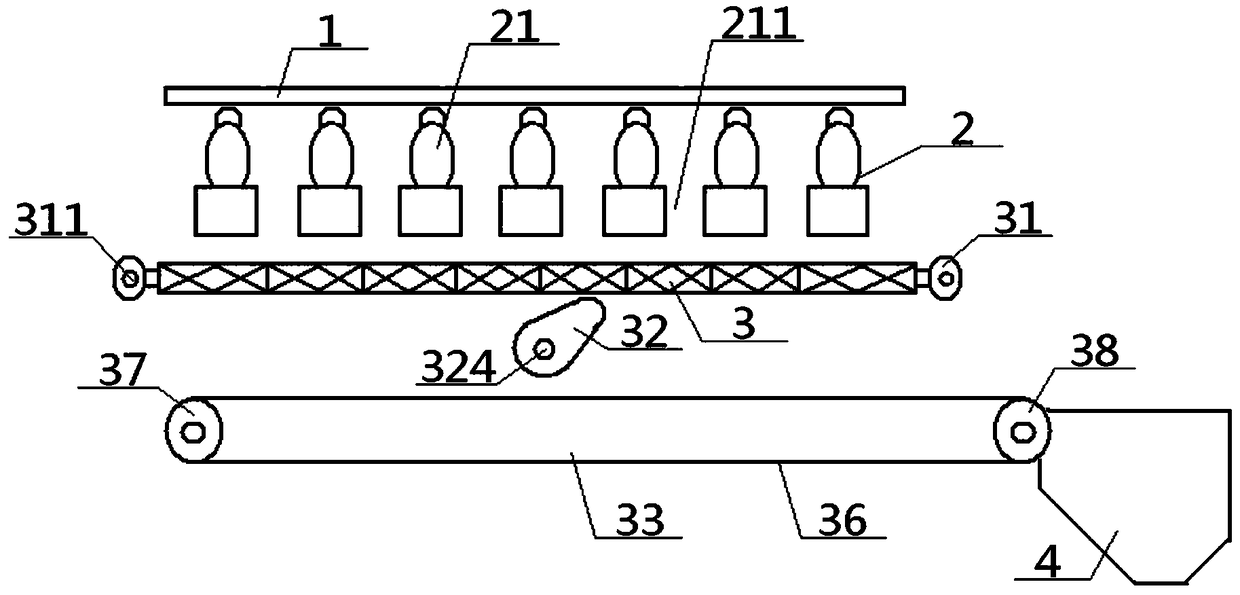

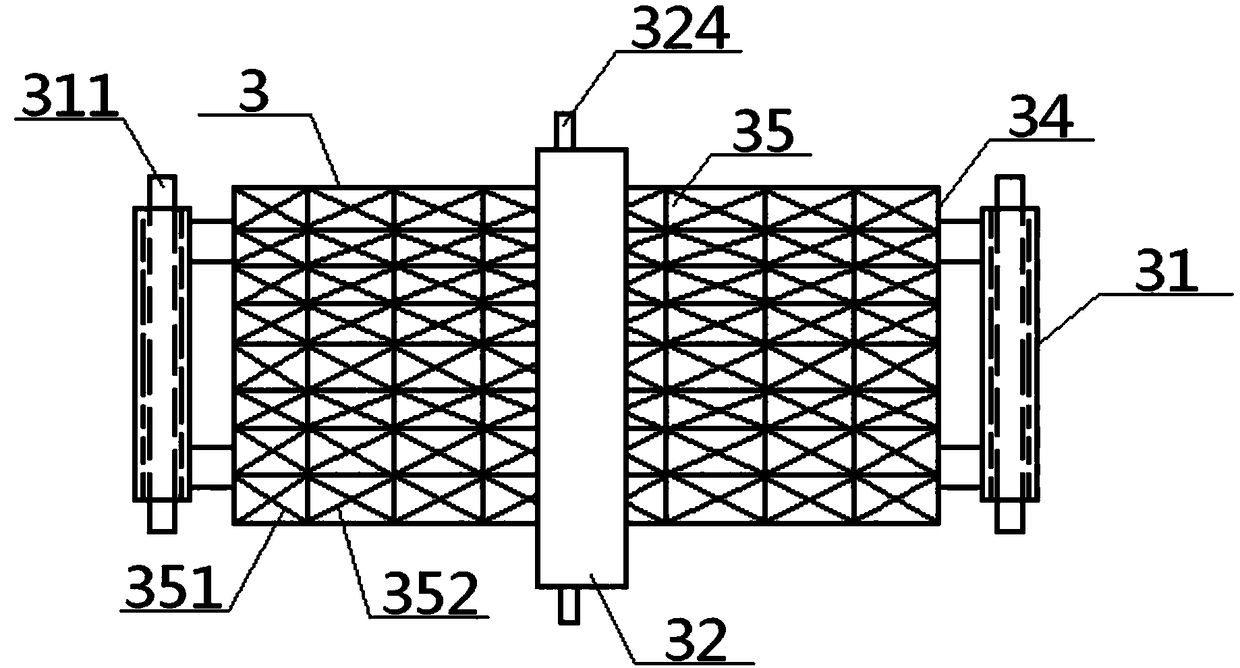

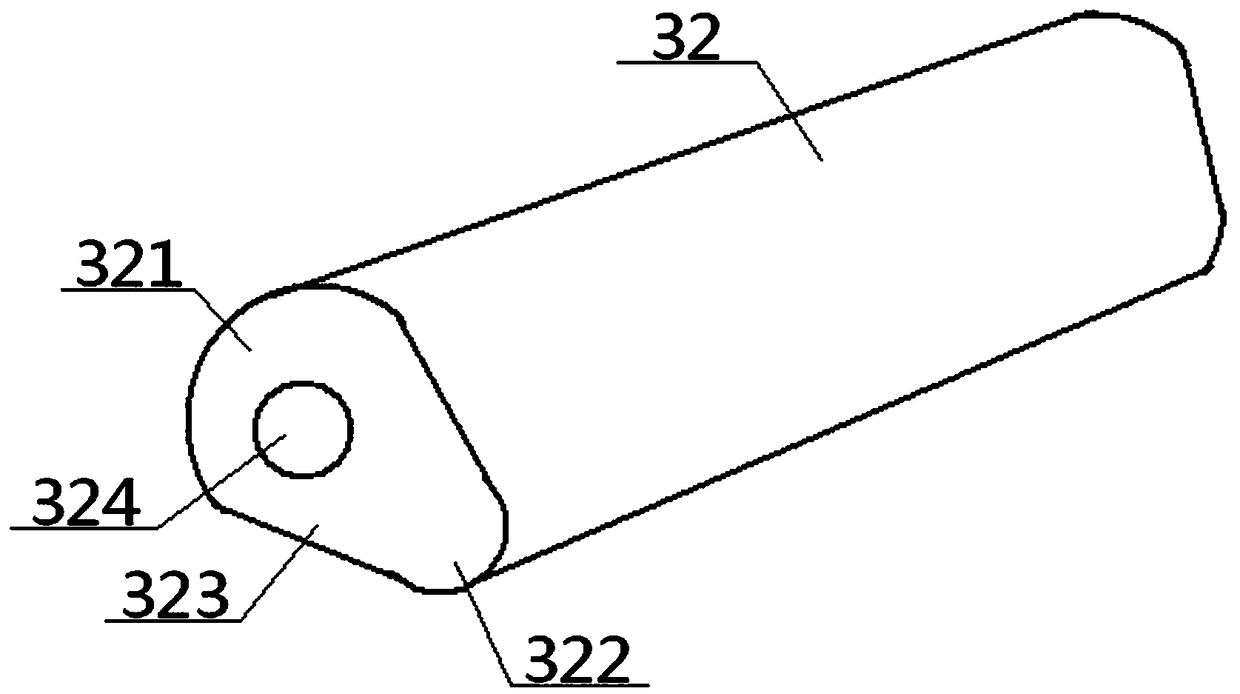

[0052] see Figure 1 to Figure 7 , a method for manufacturing a metal plate for a power boiler support beam, the manufacturing method includes the following steps: firstly place a metal plate 1 to be processed on a cutting unit 2, and the bottom surface of the metal plate 1 is supported by a strip in the cutting unit 2 The tops of the seats 21 are in contact, and the adjacent strip support seats 21 are provided with gaps 211 between the seats. , and then cut the sheet metal 1. During the cutting operation, the reciprocating sliding sleeve 31 relatively slides along the reciprocating sliding rod 311 to drive the trash net 3 to move back and forth. At the same time, the roller rotating rod 324 drives the upper bump The roller 32 rotates, and the roller rotating rod 324 reciprocates along the horizontal direction, and the rotating upper bump roller 32 lifts and lowers the trash net 3 above it at intervals, so that the trash net 3 moves up and down, back and forth The moving, up ...

Embodiment 2

[0055] Basic content is the same as embodiment 1, the difference is:

[0056] The miscellaneous device 33 includes a miscellaneous crawler belt 36, a left miscellaneous roller 37 and a right miscellaneous roller 38, and the two ends of the miscellaneous crawler belt 36 are respectively wrapped around the rollers of the left miscellaneous roller 37 and the right miscellaneous roller 38. On the surface, a plurality of miscellaneous partition strips 361 are uniformly arranged on the outer surface of the miscellaneous crawler 36, and the bottom of the miscellaneous partition strip 361 is vertically connected with the outer surface of the miscellaneous crawler 36, and the adjacent miscellaneous partition strips 361 are parallel to each other, and the adjacent miscellaneous partition strips 361 and the miscellaneous track 36 between them constitute a miscellaneous box 362 . Preferably, on the crawler belt 36 for carrying miscellaneous materials, the inside and outside sides of the p...

Embodiment 3

[0058] Basic content is the same as embodiment 1, the difference is:

[0059] The recovery unit 4 includes a recovery upper baffle plate 41, a reclaimed outer baffle plate 42, a recovery left lower slant baffle plate 43 and a recovery right lower slant baffle plate 44. Shaped plate structure, and the arc-shaped protrusions of the recovered left lower inclined baffle 43 and the recovered right lower inclined baffle 44 are facing to each other; the top of the recovered left lower inclined baffle 43 is hinged with the bottom end of the tail sweeping air pipe 431, The top air outlet of the tail sweeping air pipe 431 is arranged near the bottom surface of the outer end of the right miscellaneous roller 38, and the top surface of the outer end of the right miscellaneous roller 38 is set near the inner end of the recovery upper baffle plate 41, and the outer end of the upper baffle plate 41 is reclaimed with the The top of reclaiming the outer baffle 42 is vertically connected, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com