Preparation method of high-selectivity amino-functionalized mesoporous gamma-aluminum oxide-based composite adsorbent

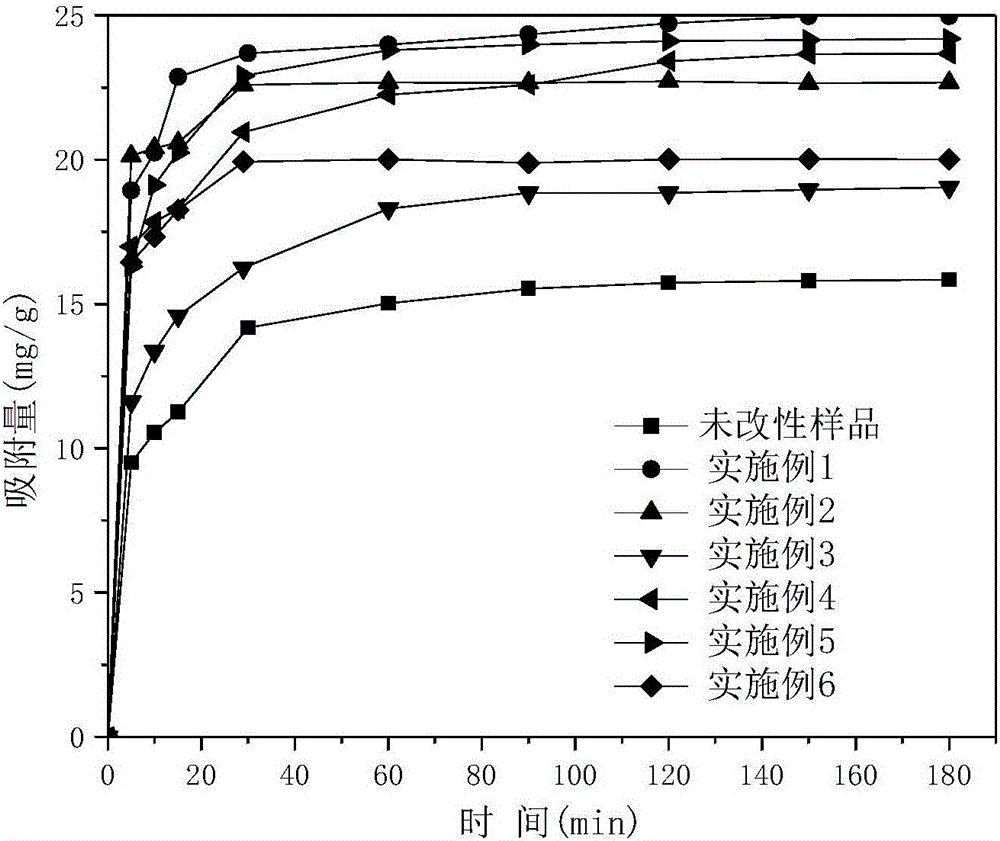

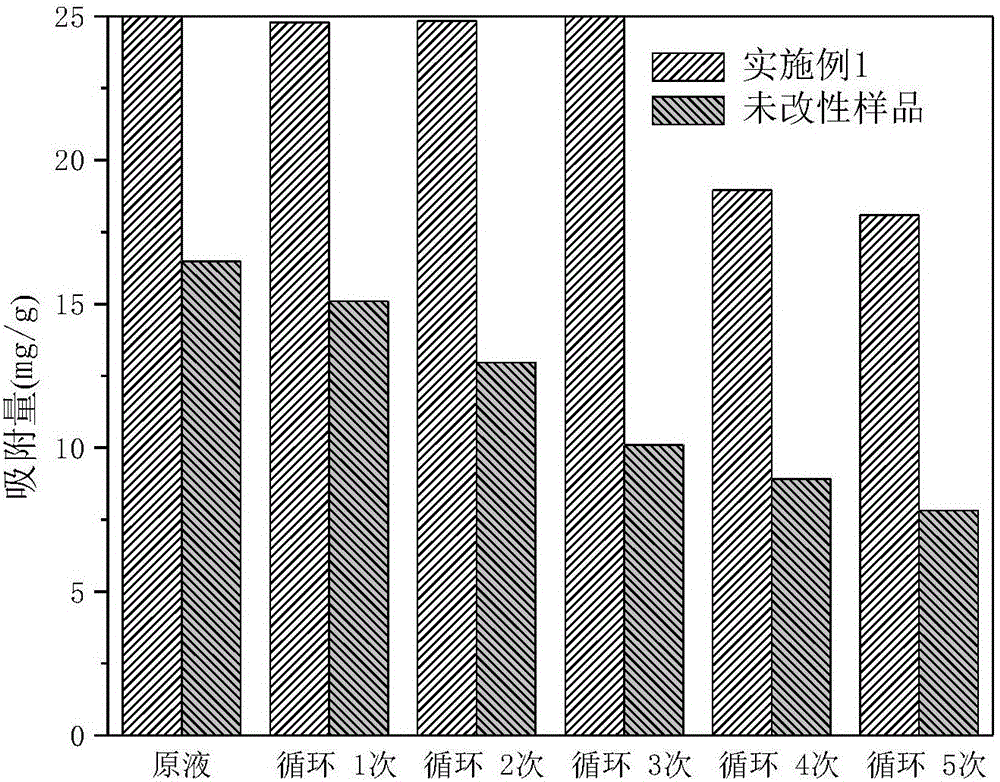

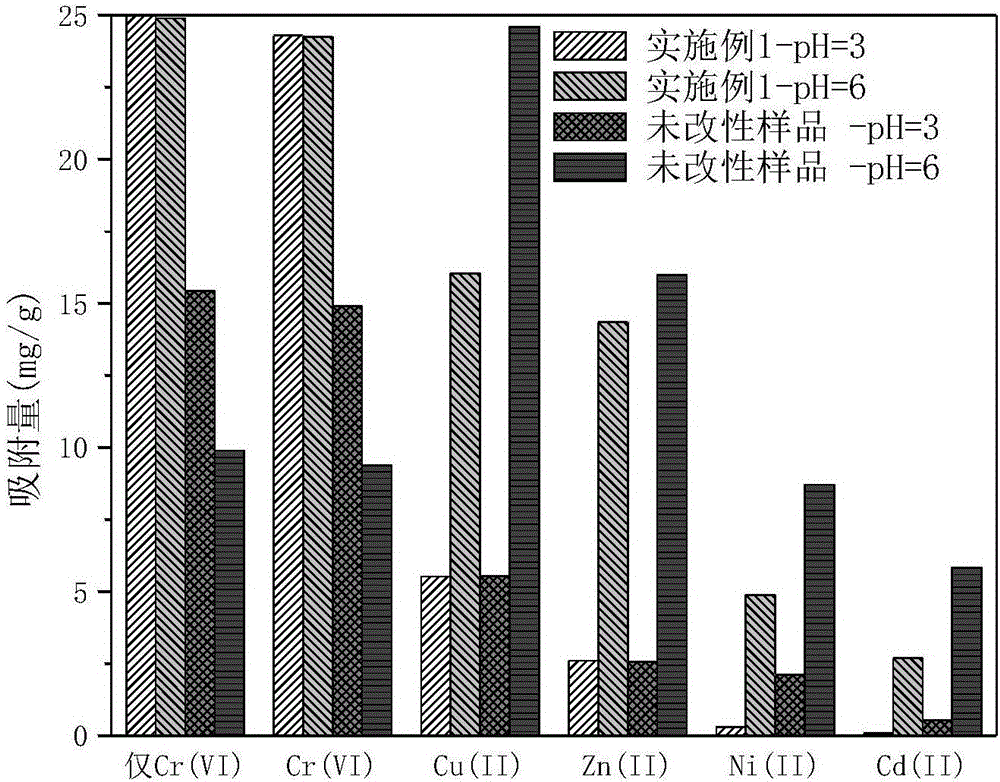

A technology of amino functionalization and composite adsorption, which is applied in the direction of chemical instruments and methods, alkali metal compounds, adsorption water/sewage treatment, etc., can solve the problems of long time consumption and environmental friendliness reduction, achieve short time consumption and increase adsorption capacity And the effect of selectivity and good recycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dissolve 1 g of P123 in 20 ml of ethanol at room temperature with thorough stirring. Next, add 1.6ml of 67%wt concentrated nitric acid, stir and mix evenly at room temperature. Then, 2.04 g of aluminum isopropoxide was added, and the mixture was fully stirred for 5 h at room temperature to obtain a solution. Put the above solution in an oven at 60°C, induce solvent evaporation for 48 hours to obtain a gel, and bake the gel at 600°C (heating rate 1°C / min) for 4 hours to obtain mesoporous γ-Al 2 o 3 Original powder. Further, at room temperature, 1 g of mesoporous γ-Al2 o 3 The former powder is dispersed in 30ml ethanol, under the stirring of 1500rpm, add dropwise 0.5g, the N-beta-(aminoethyl)-gamma-aminopropylmethyldimethoxysilane that mass concentration is 99%, at room temperature After fully stirring for 1 h, the diamino-functionalized mesoporous γ-Al was prepared by centrifugation, washing with ethanol and drying at 120 °C for 2 h. 2 o 3 base composite adsorbent....

Embodiment 2

[0035] Dissolve 1 g of P123 in 20 ml of ethanol at room temperature with thorough stirring. Next, add 1.6ml of 67%wt concentrated nitric acid, stir and mix evenly at room temperature. Then, 2.04 g of aluminum isopropoxide was added, and the mixture was fully stirred for 5 h at room temperature to obtain a solution. Put the above solution in an oven at 60°C, induce solvent evaporation for 48 hours to obtain a gel, and bake the gel at 600°C (heating rate 1°C / min) for 4 hours to obtain mesoporous γ-Al 2 o 3 Original powder. Further, at room temperature, 1 g of mesoporous γ-Al 2 o 3 The original powder was dispersed in 30ml of ethanol, and 0.25g of N-aminoethyl-γ-aminopropyltrimethoxysilane with a mass concentration of 99% was added dropwise under stirring at 1500rpm. After fully stirring at room temperature for 12h, the Diamino-functionalized mesoporous γ-Al was prepared by centrifugation, washing with ethanol and drying at 130°C for 3 h 2 o 3 base composite adsorbent.

...

Embodiment 3

[0038] Dissolve 1 g of P123 in 20 ml of ethanol at room temperature with thorough stirring. Next, add 1.6ml of 67%wt concentrated nitric acid, stir and mix evenly at room temperature. Then, 2.04 g of aluminum isopropoxide was added, and the mixture was fully stirred for 5 h at room temperature to obtain a solution. Put the above solution in an oven at 60°C, induce solvent evaporation for 48 hours to obtain a gel, and bake the gel at 600°C (heating rate 1°C / min) for 4 hours to obtain mesoporous γ-Al 2 o 3 Original powder. Further, at room temperature, 1 g of mesoporous γ-Al 2 o 3 The former powder is dispersed in 30ml ethanol, under stirring at 1500rpm, add 1g dropwise, mass concentration is 99% 3-[2-(2-aminoethylamino)ethylamino]propyl-trimethoxysilane, at room temperature After fully stirring at high temperature for 6 h, it was centrifuged, washed with ethanol and dried at 110 °C for 1 h to prepare the triamino-functionalized mesoporous 2 o 3 base composite adsorbent. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com