Preparation method of amorphous ferrisodium silicate nano-sheet with selective adsorption performance

A technology with adsorption performance and selectivity, applied in chemical instruments and methods, adsorption water/sewage treatment, silicon compounds, etc., can solve the problem that the potential application of NaFeSi2O6 is rarely studied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in combination with specific embodiments.

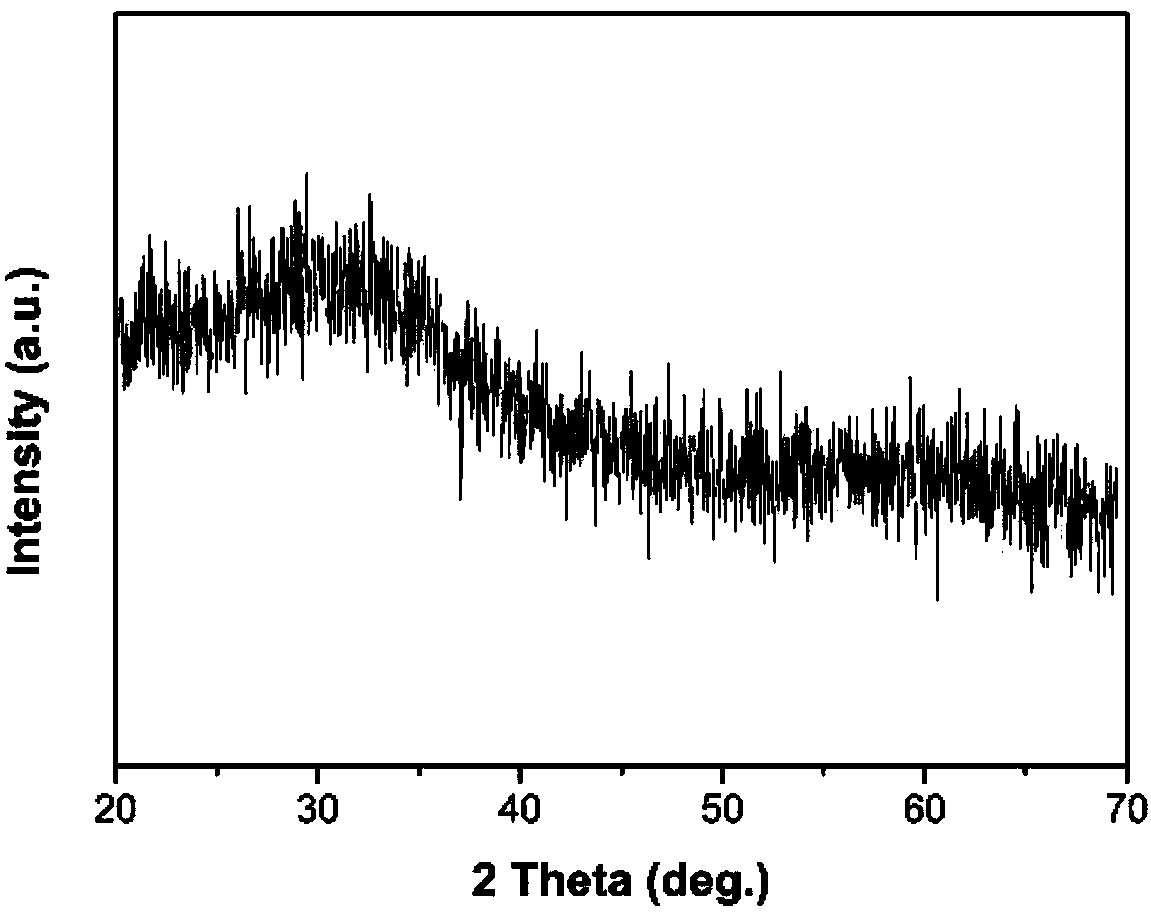

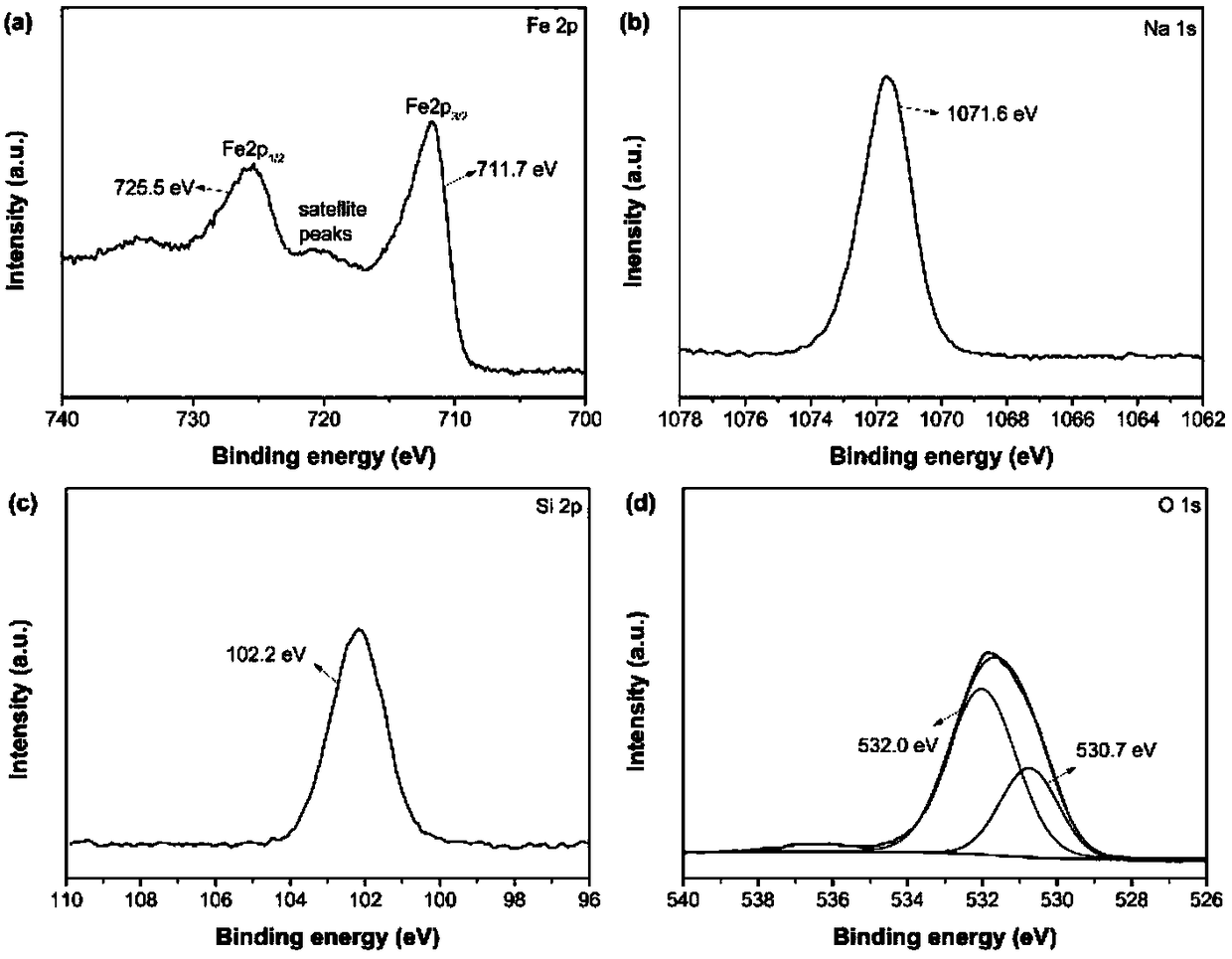

[0024] Preparation of Amorphous Sodium Iron Silicate Nanosheets

[0025] The synthesis method is as follows: 2.5296gNa 2 SiO 3 9H 2 O was dissolved in 30mL mixed solvent (15mL each of deionized water and absolute ethanol), and magnetically stirred until completely dissolved to obtain solution A; 2.3836g Fe(NO 3 ) 3 9H 2 O was dissolved in 30mL mixed solvent (15mL each of deionized water and absolute ethanol), and magnetically stirred until completely dissolved to obtain solution B; control the dropping speed (1-2 drops / second), slowly add B liquid into A liquid, drop During the addition process, stir with a magnetic stirrer all the time. After all the drops are completed, continue to stir for 1 hour, then transfer the suspension to an 80 mL stainless steel autoclave with a polytetrafluoroethylene liner and seal it, and react at 160 ° C for 12 hours. , after naturall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com