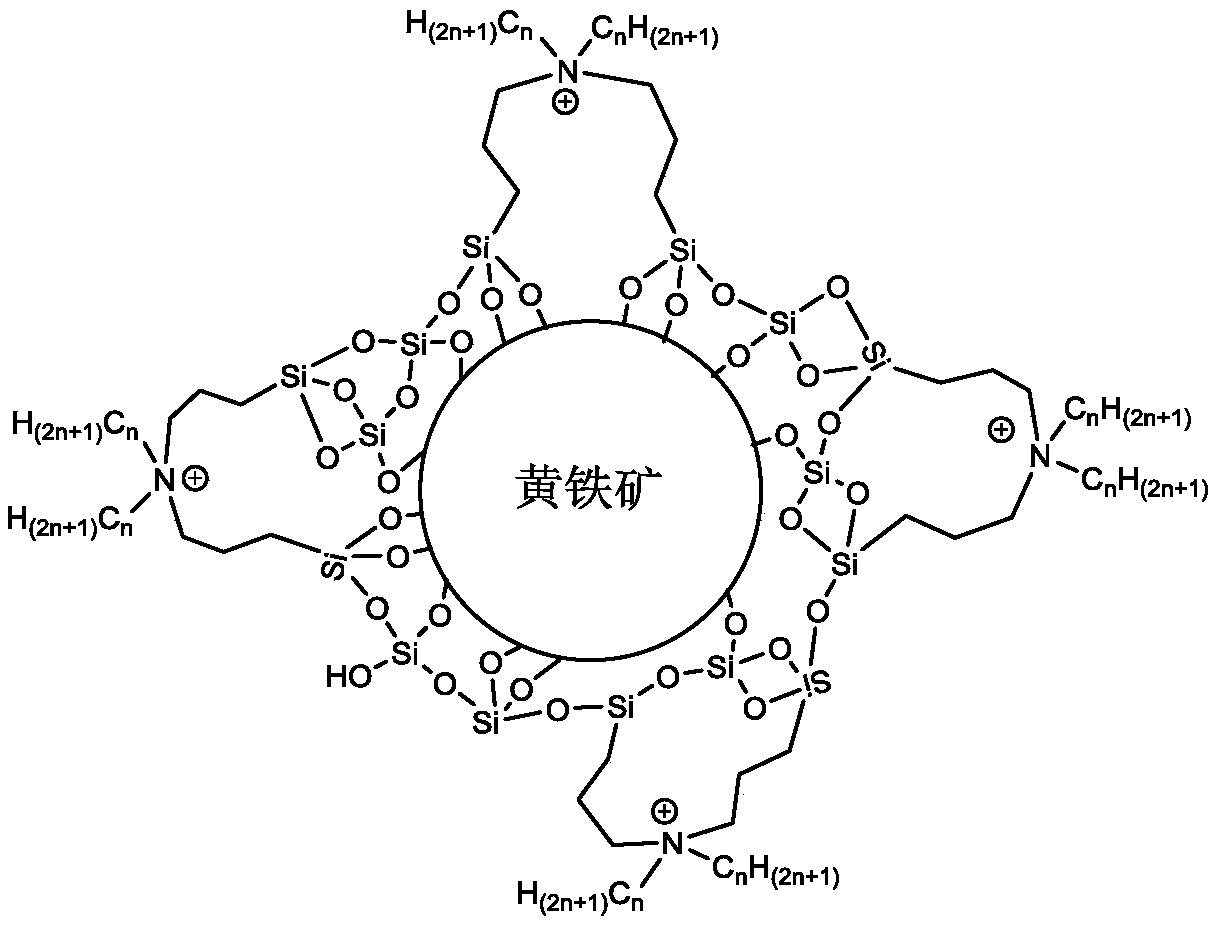

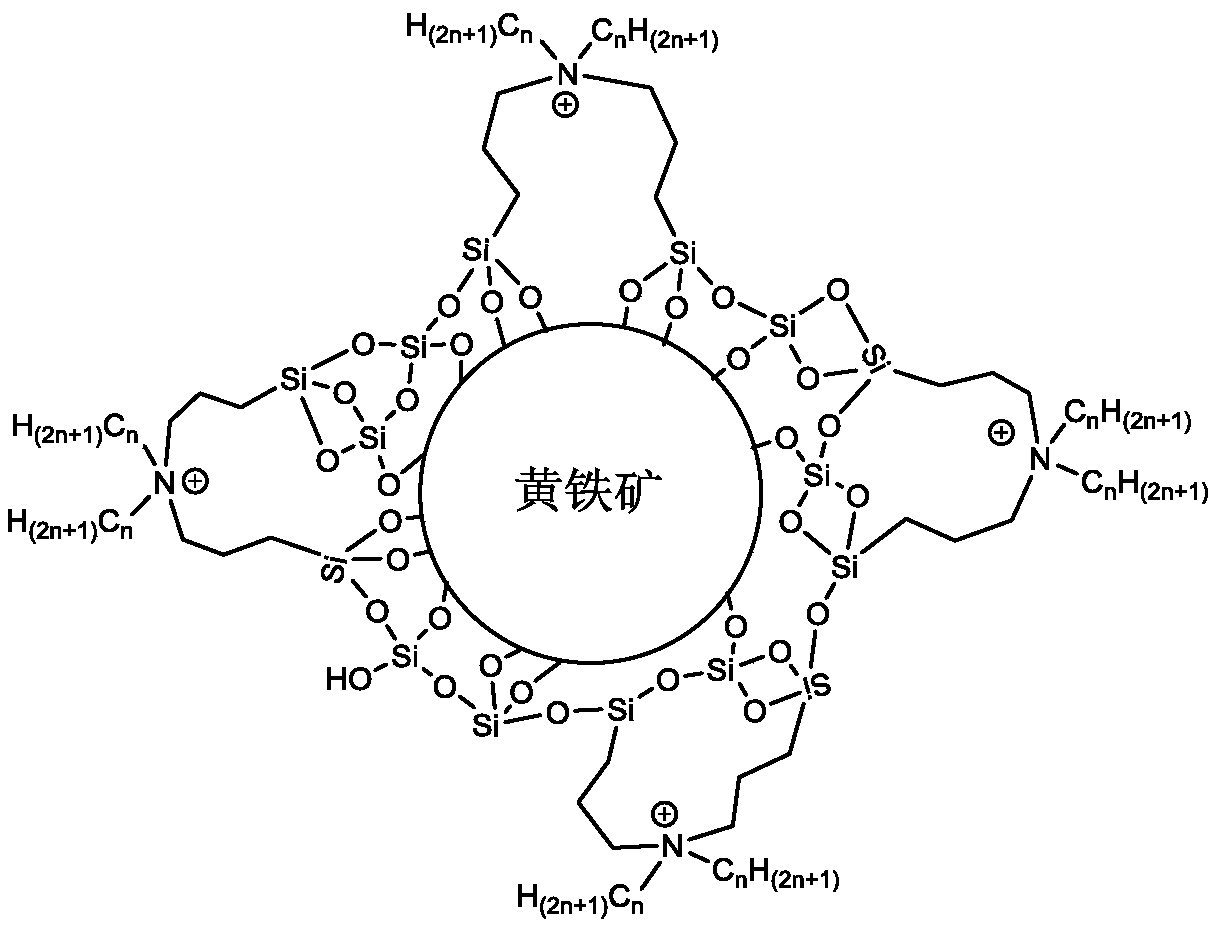

An organic-inorganic hybrid material for processing heavy metals and its preparation method

A technology of hybrid materials and heavy metals, which is applied in the fields of silicon organic compounds, chemical instruments and methods, water/sewage treatment, etc., can solve the problems such as the inability to achieve selective adsorption, the inability to selectively adsorb Cr, and the inability to achieve effective separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

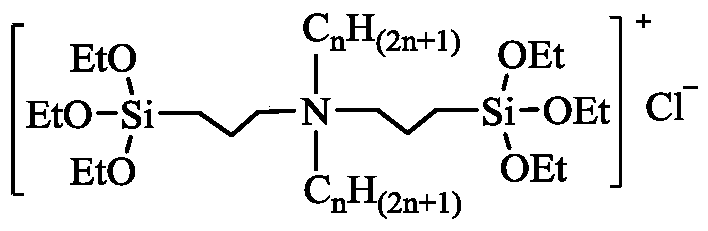

Embodiment 1

[0026] First add 20g of sodium iodide to 70g of diethylamine, after mixing evenly, raise the temperature to 100°C under the protection of nitrogen, then slowly add 208g of 3-chloropropyltriethoxysilane to diethylamine and sodium iodide In the mixture, react for 8 hours, cool down to room temperature; add 47g of sodium methoxide, and remove methanol by distillation under reduced pressure after reacting for 2 hours; slowly add 208g of 3-chloropropyltriethoxysilane again, and react at 100°C under nitrogen protection for 10 hour, filtered, and the filtrate was distilled off under reduced pressure to remove the solvent, and then recrystallized with acetone / ether mixed solvent to obtain bis(3-(triethoxysilyl)propyl)diethylammonium chloride, which was dried for future use.

[0027] The pyrite powder was ground to 100 mesh under the protection of inert gas. Wash with hydrochloric acid ethanol solution and absolute ethanol, and vacuum dry in an inert gas environment.

[0028] Add 20g ...

Embodiment 2

[0031] Concrete steps are identical with embodiment 1. But the pyrite powder is 10 mesh. The hybrid material has a removal rate of 19% for Cr(Ⅵ) and 14% for Re(VII).

Embodiment 3

[0033] Concrete steps are identical with embodiment 2. However, in the preparation step of the organic-inorganic hybrid material, pyrite powder was reacted with silylated dialkyl quaternary ammonium salt and tetraethyl orthosilicate at 30° C. for 48 hours. The hybrid material has a removal rate of 21% for Cr(Ⅵ) and 15% for Re(VII).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com