Nano composite fiber membrane capable of efficiently removing ionic dyes and heavy metal ions in water as well as preparation method and application of nano composite fiber membrane

A nano-composite fiber, heavy metal ion technology, applied in the directions of alkali metal compounds, fiber treatment, water pollutants, etc., can solve the problems of incomplete removal of pollutants, difficult separation, inconvenient operation, etc., and achieve good mechanical properties and recycling capacity. , The activation process is simple and the structure is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

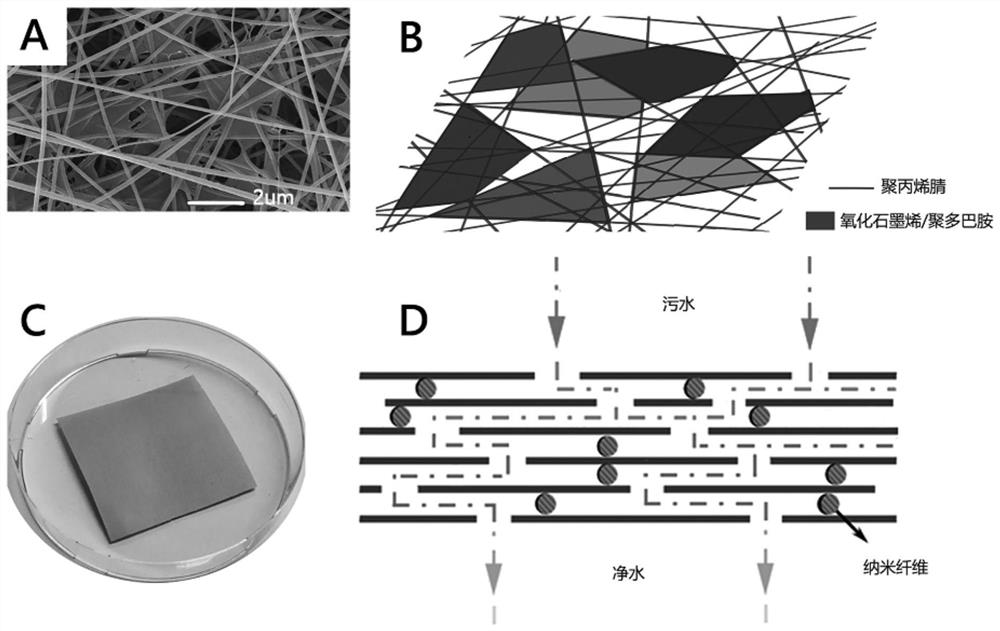

[0035] The present invention constructs a kind of nanofiber composite film with electrospinning fiber and graphene oxide as the building block, and through dopamine modification, it becomes a pair of ionic dyes (such as methylene blue, chrome black T) and heavy metal ions (such as Cu 2+ ) Materials with adsorption function. The preparation method of nanofiber composite film comprises the following steps:

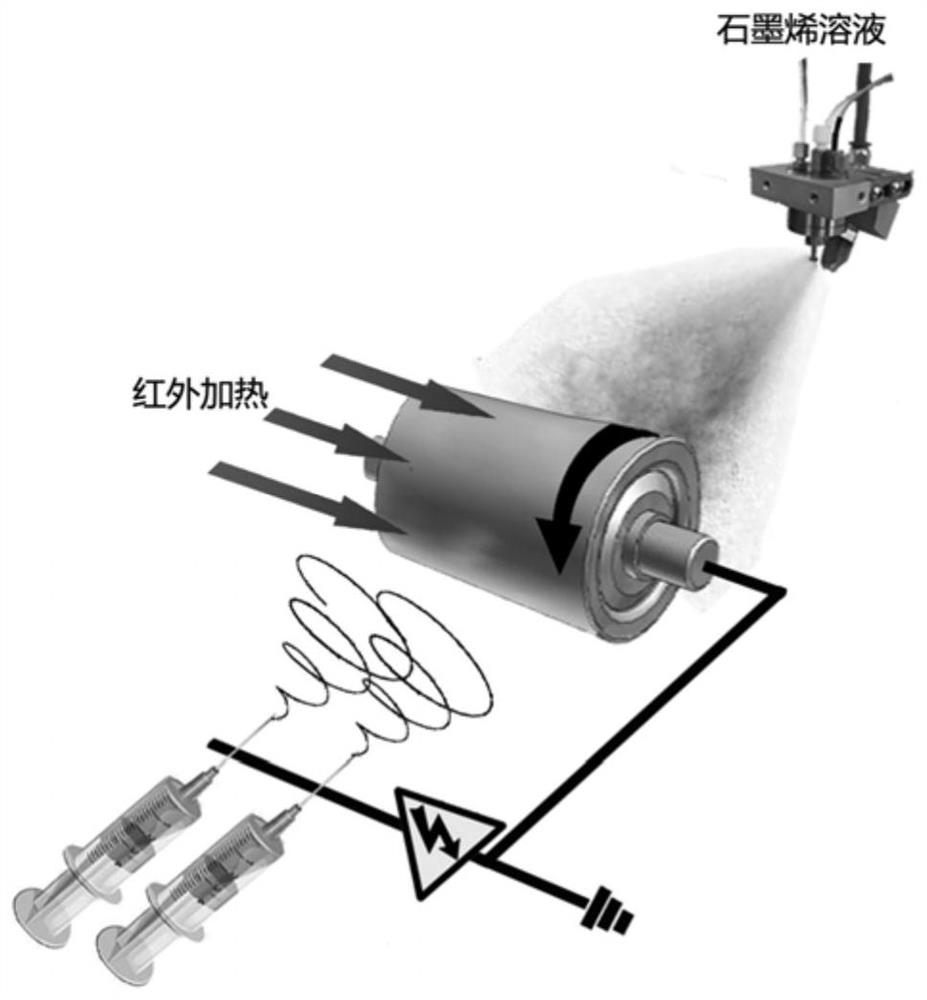

[0036] (1) Preparation of polyacrylonitrile electrospun nanofibers and graphene oxide composite membranes (PAN / GO NFMs): The membrane preparation is divided into electrospinning part and ultrasonic spraying part, which are carried out on both sides of the receiving device at the same time; the PAN (Polyacrylonitrile) was dissolved in a solvent, prepared into a uniform PAN solution, and then prepared into a fibrous film by electrospinning; prepared an ethanol solution of GO, and sprayed it on the fiber prepared by electrospinning by ultrasonic spraying On the membrane: Elec...

Embodiment 1

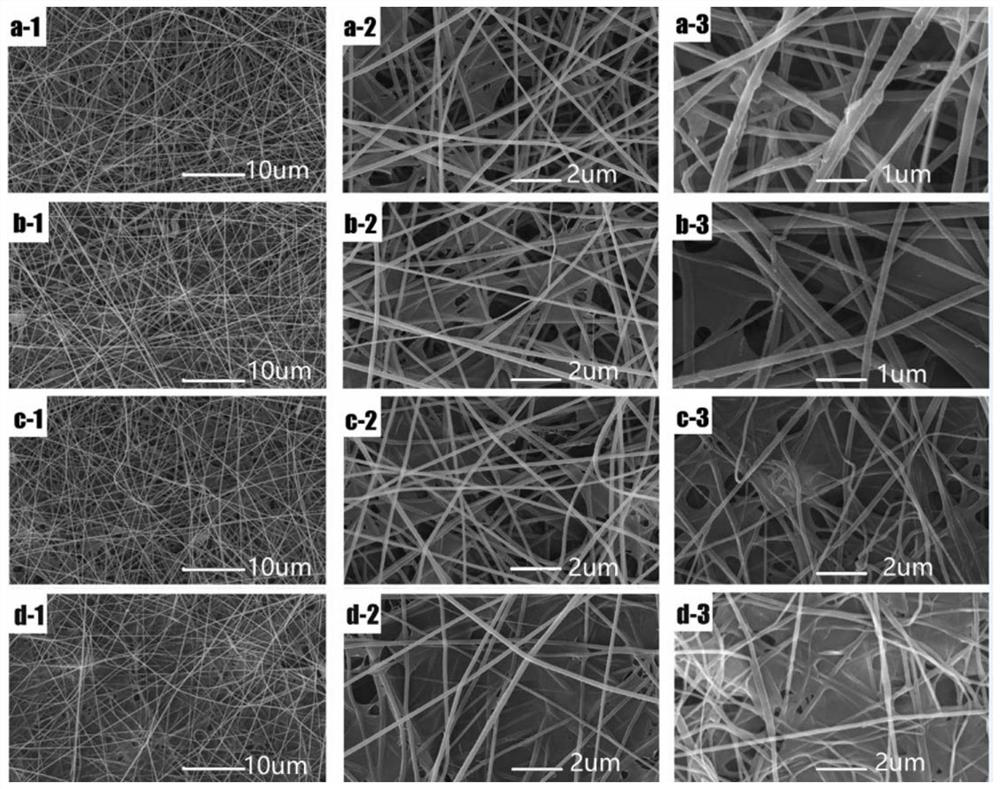

[0056] (1) Preparation of polyacrylonitrile electrospun nanofiber membrane (PAN NFMs): PAN is dissolved in DMF, stirred evenly, and prepared into a homogeneous solution (concentration 9wt.%), at room temperature and humidity of 45 ± 2% conditions PAN NFMs were prepared by electrospinning under high conditions. The injection speed of PAN solution was 0.5mL / h, the voltage was 14kV, the fiber receiving distance was 12cm, and the receiving device was a metal roller with a rotation speed of 200r / min.

[0057] (2) Preparation of polyacrylonitrile electrospun nanofibers and graphene oxide composite membranes (PAN / GO NFMs): The membrane preparation is divided into electrospinning part and ultrasonic spraying part, which are carried out on both sides of the receiving roller at the same time, such as figure 2 . The technical parameters of the electrospinning part are the same as step (1), the spraying solution is ethanol solution (0.25mg / mL) of GO, the ultrasonic spraying power is 18W,...

Embodiment 2

[0060] (1) Preparation of polyacrylonitrile electrospun nanofiber membrane (PAN NFMs): PAN is dissolved in DMF, stirred evenly, prepared into a homogeneous solution (concentration 10wt.%), at room temperature and humidity 45 ± 2% conditions PAN NFMs were prepared by electrospinning under high temperature conditions. The injection speed of PAN solution was 0.8mL / h, the voltage was 16kV, the fiber receiving distance was 16cm, and the receiving device was a metal roller with a rotation speed of 200r / min.

[0061] (2) Preparation of polyacrylonitrile electrospun nanofibers and graphene oxide composite membranes (PAN / GO NFMs): The membrane preparation is divided into electrospinning part and ultrasonic spraying part, which are carried out on both sides of the receiving roller at the same time, such as figure 2. The technical parameters of the electrospinning part are the same as in step (1), the spraying solution is GO ethanol solution (0.3mg / mL), the ultrasonic spraying power is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com