Preparation method and application of iminodiacetic acid functionalized magnetic adsorption material

A magnetic adsorption material, iminodiacetic acid technology, applied in chemical instruments and methods, adsorption water/sewage treatment, inorganic chemistry, etc., can solve the problems of difficult recycling, limited research application, unstable adsorption, etc., and achieve adsorption effect. Stable, large specific surface area, easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 of the present invention provides a preparation method of iminodiacetic acid functionalized magnetic adsorption material, comprising the following steps:

[0034] Step S101, weighing 2.7gFeCl 3 ·6H 2 O was dissolved in 125mL of ethylene glycol, and 7.2g of sodium acetate (NaAc) was added after it was completely dissolved. After ultrasonication for 20min, the mixed solution was poured into a polytetrafluoroethylene reactor, and reacted at 200°C for 8h; The boron magnet adsorbs the solid product from the solution. After washing, put the solid product in a vacuum drying oven and dry it at 60°C for 2 hours to obtain the magnetic Fe 3 o 4 powder;

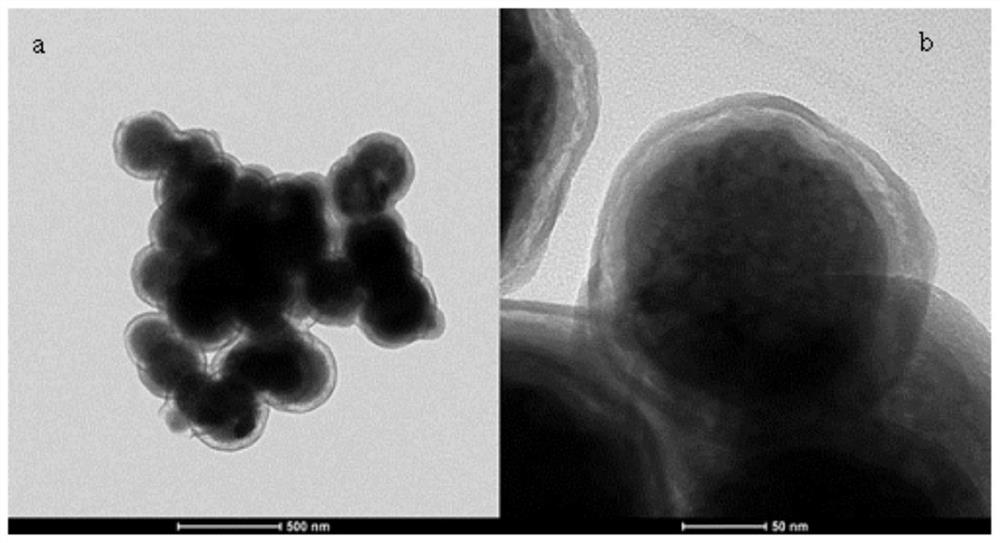

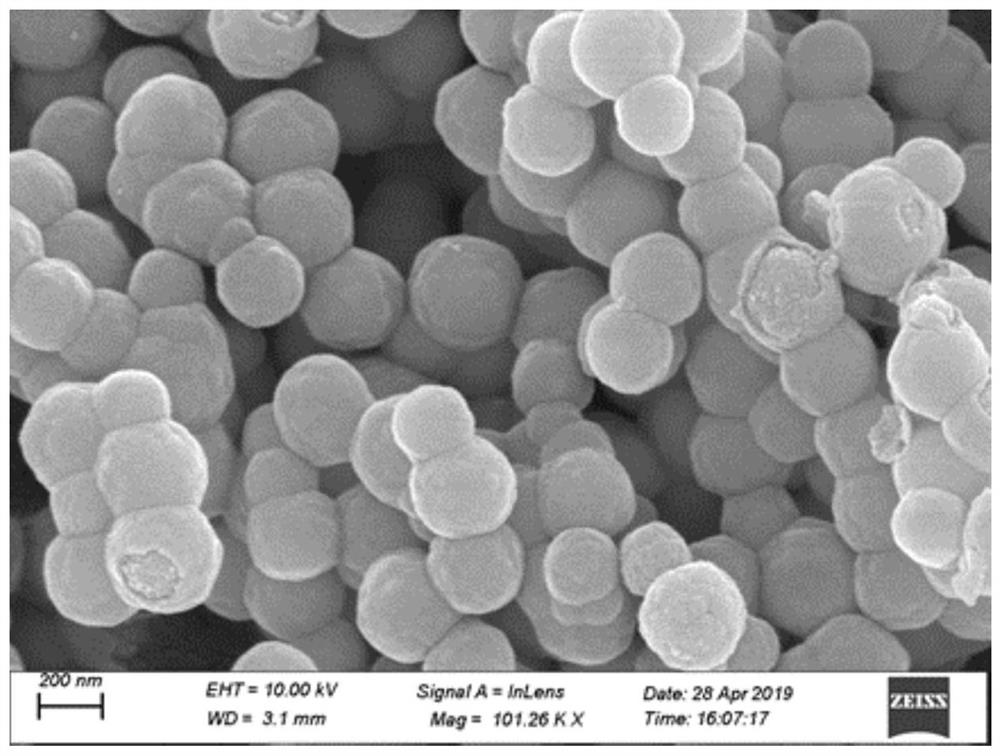

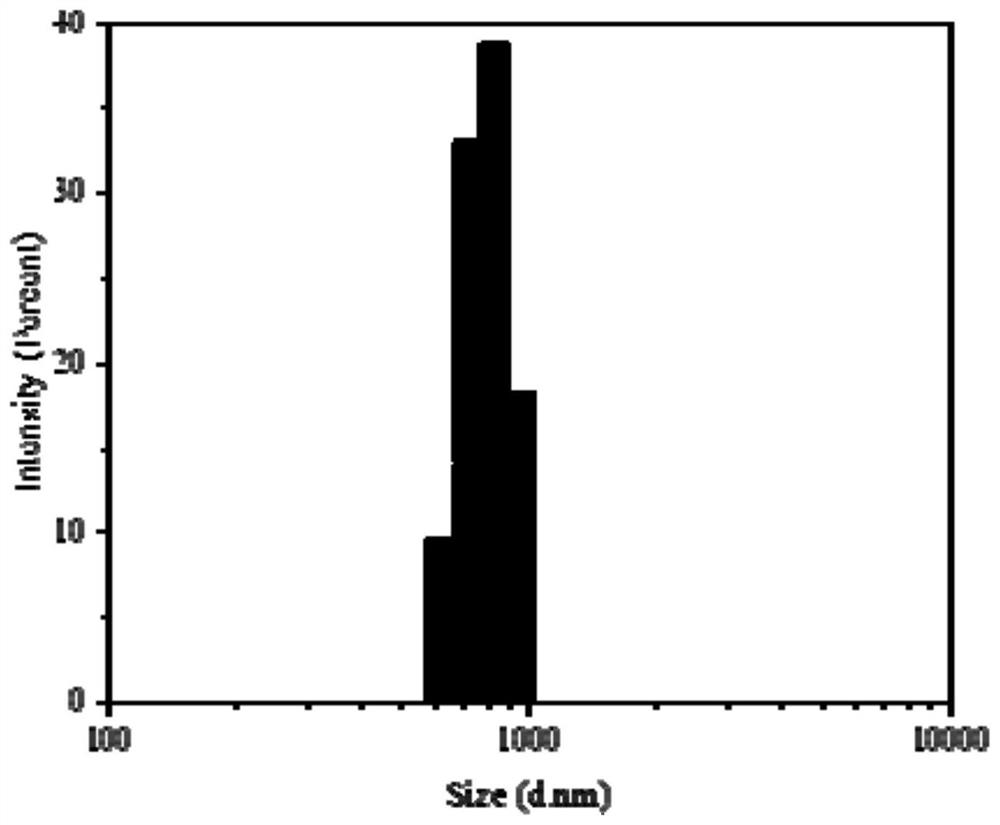

[0035] Step S102, weighing 150mg of magnetic Fe 3 o 4 Put the powder in a 250mL beaker, add 120mL of absolute ethanol and 30mL of deionized water, ultrasonically disperse for 30min, add 1.5mL of concentrated ammonia water with a concentration of 22% to 25% during the stirring process, and then add 250μL tetraethy...

Embodiment 2

[0049] Embodiment 2 of the present invention provides a kind of preparation method of iminodiacetic acid functionalized magnetic adsorption material, comprising the following steps:

[0050] Step S101, weighing 2.7gFeCl 3 ·6H 2 O was dissolved in 125mL of ethylene glycol, and 7.2g of sodium acetate was added after it was completely dissolved. After ultrasonication for 20min, the mixed solution was poured into a polytetrafluoroethylene reactor, and reacted at 210°C for 7h; after the reaction was completed, the NdFeB magnet was used to The solid product is adsorbed from the solution, and after washing, the solid product is put into a vacuum drying oven and dried at 60°C for 2 hours to obtain a magnetic Fe 3 o 4 powder;

[0051] Step S102, weighing 150mg of magnetic Fe 3 o 4 Put the powder in a 250mL beaker, add 119mL of absolute ethanol and 29mL of deionized water, and ultrasonically disperse for 30 minutes; add 1.5mL of concentrated ammonia water with a concentration of 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com