Preparation method and application of cyclodextrin improved biomass coffee grounds

A technology of coffee grounds and cyclodextrin, applied in separation methods, chemical instruments and methods, water pollutants, etc., can solve the problems of limiting the application of activated sludge method, improving the toxicity of water pollutants, etc., and achieve excellent recycling ability, Achieve multiple recycling and improve the effect of combining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of cyclodextrin improved biomass coffee grounds of the present embodiment, comprises the following steps:

[0031] Step 1, coffee grounds pretreatment: wash and filter the coffee grounds first, then irradiate with ultraviolet light with a wavelength of 0.2mm under vacuum conditions for 10 minutes, and then place them in an activation solution for activation treatment. The activation treatment uses a mass fraction of Soak in 40-% rare earth lanthanum chloride solution for 10 minutes, and the soaking temperature is 70°C;

[0032] Step 2: Preparation of activated carbon from coffee grounds: Dry the pretreated coffee grounds in a drying oven at a drying temperature of 55°C and a drying time of 5 hours, then send them into a tube furnace with protective gas for carbonization treatment first Then, sinter at 400°C for 2h, carbonize first at 100°C for 25min, then raise the temperature to 3°C at a rate of 3°C / min, and keep it for 1h;

[0033] Step 3...

Embodiment 2

[0038] A kind of preparation method of cyclodextrin improved biomass coffee grounds of the present embodiment, comprises the following steps:

[0039] Step 1, coffee grounds pretreatment: wash and filter the coffee grounds first, then irradiate them with ultraviolet light with a wavelength of 0.5mm for 20 minutes under vacuum conditions, and then place them in an activation solution for activation treatment. The activation treatment uses mass fraction Soak in 50% rare earth lanthanum chloride solution for 20 minutes, and the soaking temperature is 80°C;

[0040] Step 2: Preparation of activated carbon from coffee grounds: Dry the pretreated coffee grounds in a drying oven at a temperature of 65°C and a drying time of 9 hours, then send them into a tube furnace with protective gas for carbonization treatment Then, sinter at 800°C for 10h, and carbonize first at 100°C for 35min, then raise the temperature to 350°C at a rate of 6°C / min, and keep it warm for 2h;

[0041]Step 3, m...

Embodiment 3

[0046] A kind of preparation method of cyclodextrin improved biomass coffee grounds of the present embodiment, comprises the following steps:

[0047] Step 1, coffee grounds pretreatment: wash and filter the coffee grounds first, then irradiate them with ultraviolet light with a wavelength of 0.35mm for 15 minutes under vacuum conditions, and then place them in an activation solution for activation treatment. The activation treatment uses mass fraction Soak in 45% rare earth lanthanum chloride solution for 15 minutes, and the soaking temperature is 75°C;

[0048] Step 2: Preparation of activated carbon from coffee grounds: Dry the pretreated coffee grounds in a drying oven at a drying temperature of 60°C and a drying time of 7 hours, then send them into a tube furnace with protective gas for carbonization treatment first Then, sinter at 600°C for 6h, carbonize first at 100°C for 30min, then raise the temperature to 350°C at a rate of 4.5°C / min, and keep it warm for 1.5h;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

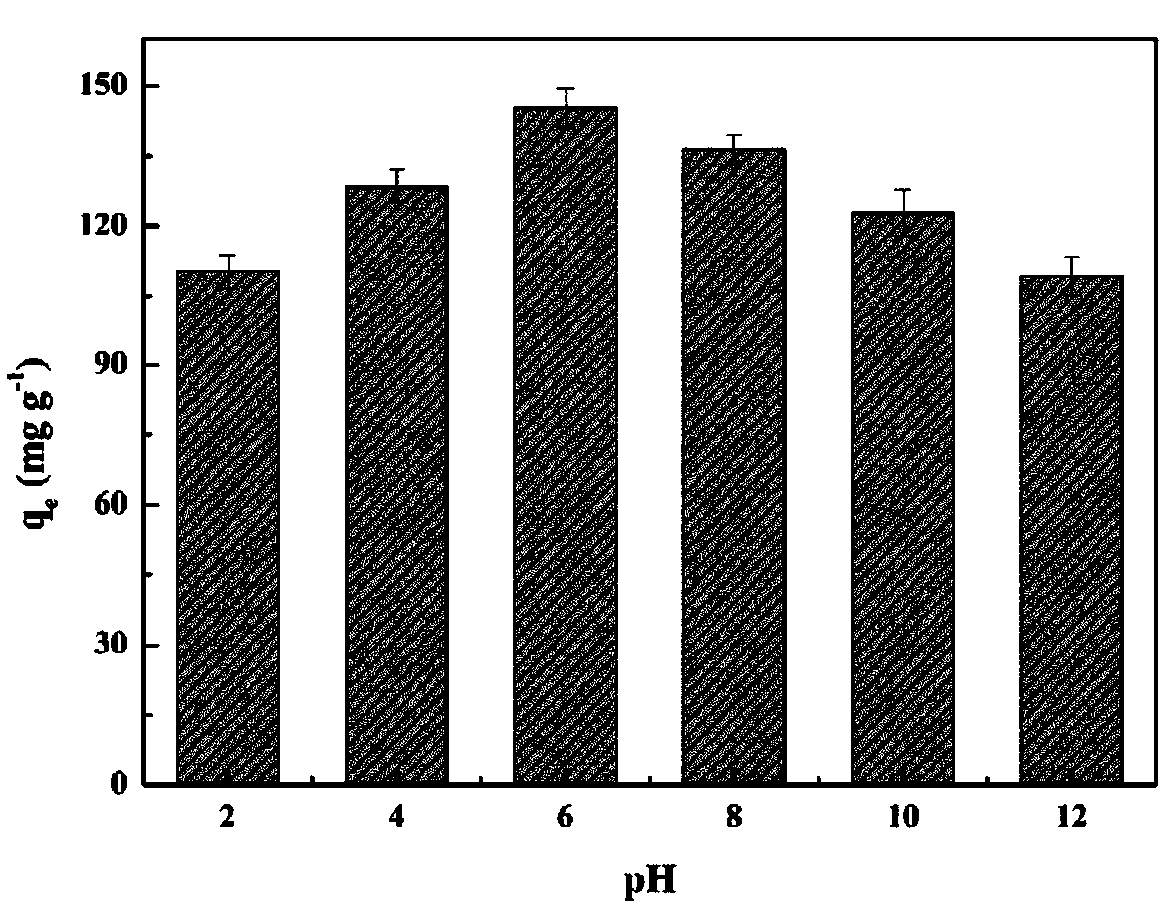

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com