Road modified asphalt

A technology for modifying asphalt and roads, which is applied to building components, building insulation materials, buildings, etc., to achieve the effects of wide sources, good economic and social benefits, and improved flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

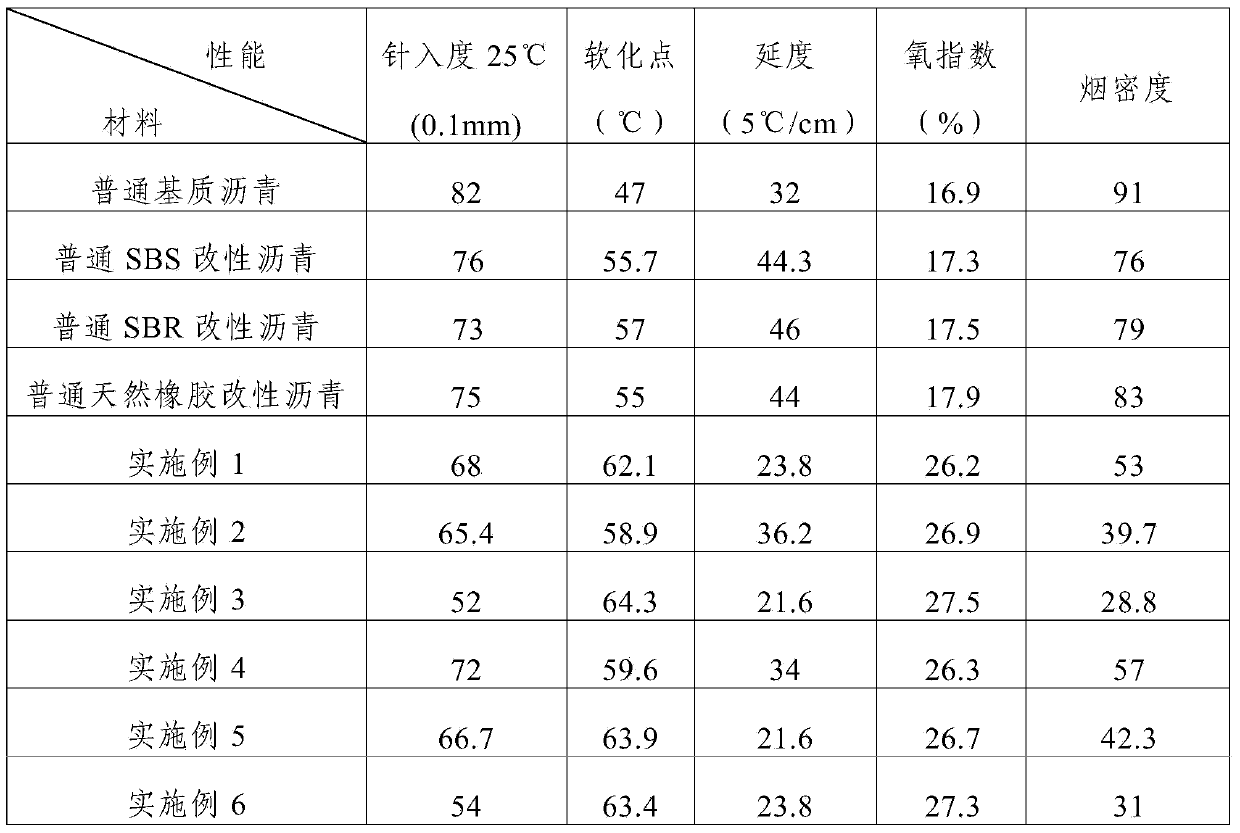

Examples

Embodiment 1

[0024] The road modified asphalt in this embodiment is made from the following raw materials: 100 parts of asphalt, 2 parts of spodumene powder, 0.45 part of boronite powder, 0.07 part of crosslinking agent, 0.08 part of diphenylamine, and 0.04 part of nonylphenol; the asphalt is Ordinary base asphalt; the cross-linking agent is methyl orthosilicate.

[0025] The preparation method of the present embodiment road modified asphalt is:

[0026] Step 1. Heat the asphalt to 160°C, then add spodumene powder and boromagnesite powder into the heated asphalt and stir evenly;

[0027] Step 2, adding the crosslinking agent to the asphalt with spodumene powder and boronite powder in step 1, and then using a high-speed shearer to shear the asphalt with the crosslinking agent at a shear rate of 1400rpm for 10min;

[0028] Step 3, adding diphenylamine to the bitumen after shearing in step 2, and then using a high-speed shearer to shear the bitumen added with diphenylamine at a shear rate of...

Embodiment 2

[0032] The road modified asphalt in this embodiment is made of the following raw materials: 100 parts of asphalt, 5.5 parts of spodumene powder, 1.975 parts of boronite powder, 0.285 part of crosslinking agent, 0.34 part of diphenylamine, and 0.17 part of nonylphenol; the asphalt is SBS modified asphalt; the crosslinking agent is aluminum isopropoxide.

[0033] The preparation method of the present embodiment road modified asphalt is:

[0034] Step 1. Heat the asphalt to 165°C, then add spodumene powder and boronite powder into the heated asphalt and stir evenly;

[0035] Step 2, adding the cross-linking agent to the asphalt with spodumene powder and boronite powder in step 1, and then using a high-speed shearer to shear the asphalt with the cross-linking agent at a shear rate of 1600 rpm for 13 minutes;

[0036] Step 3, adding diphenylamine to the bitumen after shearing in step 2, and then using a high-speed shearer to shear the bitumen added with diphenylamine at a shear ra...

Embodiment 3

[0040] The road modified asphalt in this embodiment is made of the following raw materials: 100 parts of asphalt, 9 parts of spodumene powder, 3.5 parts of boronite powder, 0.5 part of crosslinking agent, 0.6 part of diphenylamine, and 0.3 part of nonylphenol; the asphalt is SBR modified asphalt; the crosslinking agent is titanium acetylacetonate.

[0041] The preparation method of the present embodiment road modified asphalt is:

[0042] Step 1. Heat the asphalt to 170°C, then add spodumene powder and boronite powder into the heated asphalt and stir evenly;

[0043] Step 2, adding the cross-linking agent to the asphalt with spodumene powder and boronite powder in step 1, and then using a high-speed shearer to shear the asphalt with the cross-linking agent at a shear rate of 1800rpm for 15min;

[0044] Step 3, adding diphenylamine to the bitumen after shearing in step 2, and then using a high-speed shearer to shear the bitumen added with diphenylamine at a shear rate of 4500r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com