Cooling liquid for cutting

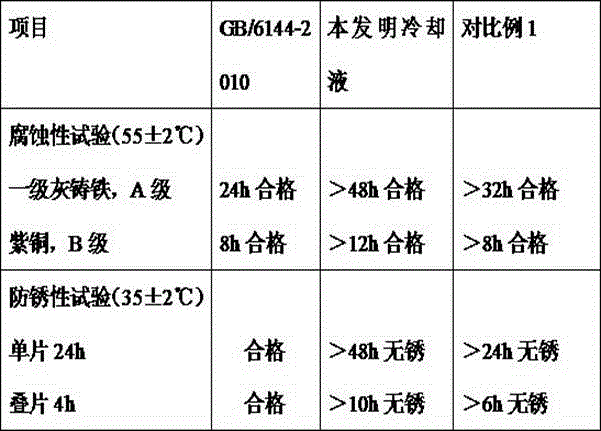

A technology of cooling liquid and ethylene glycol, applied in the petroleum industry, lubricating composition, etc., can solve the problems of difficult disposal of waste liquid, human and environmental hazards, etc., to achieve strong cooling performance, ensure effective circulation, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A cooling liquid for cutting, made of the following components in parts by weight, ethylene glycol 80, castor oil 7, dimethyl silicone oil 8, methyl orthosilicate 5, sodium borate 0.5, dodecanedioic acid 10, Nano diatomite 3, lauric acid 8, urotropine 2, comfrey oil 0.3, corrosion inhibitor 0.1, defoamer 0.6, auxiliary agent 1, water 78;

[0022] The corrosion inhibitor is made of the following components in parts by weight: rosin 4, isopropanol 1, lotus seed 15, grain bud 12, ephedra 1, lotus leaf 8, tea tree leaf 15, and the tea tree leaf is 2 years or above, its preparation method is:

[0023] 1) Wash and dry lotus seeds, grain buds, ephedra, lotus leaves, and tea leaves, then crush them for later use;

[0024] 2) Put the crushed plants into an alcohol solution with a mass concentration of 92%, mix them evenly, add them to a high mixer, and stir them at a speed of 1200r / min for 25 minutes to obtain a mixture 1;

[0025] 3) Put the above mixture 1 in an ultrasonic e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com