Method for preparing silica aerogel and self-hydrophobic silica aerogel heat preservation felt pad through one-step technology

A silica and aerogel technology, applied in the field of materials, can solve the problems of complex process flow, acid catalyst corrosion, shortening processing cycle, etc., and achieve the effect of widening the application field, good void structure, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

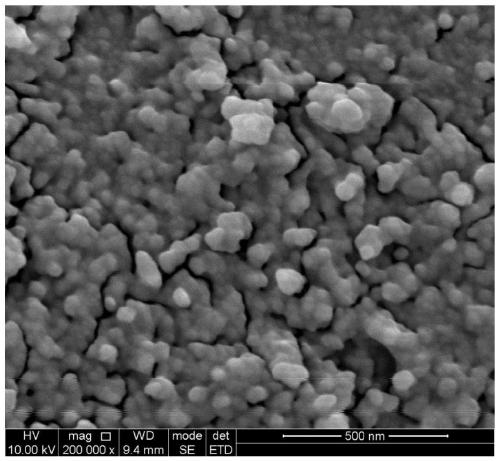

Embodiment 1

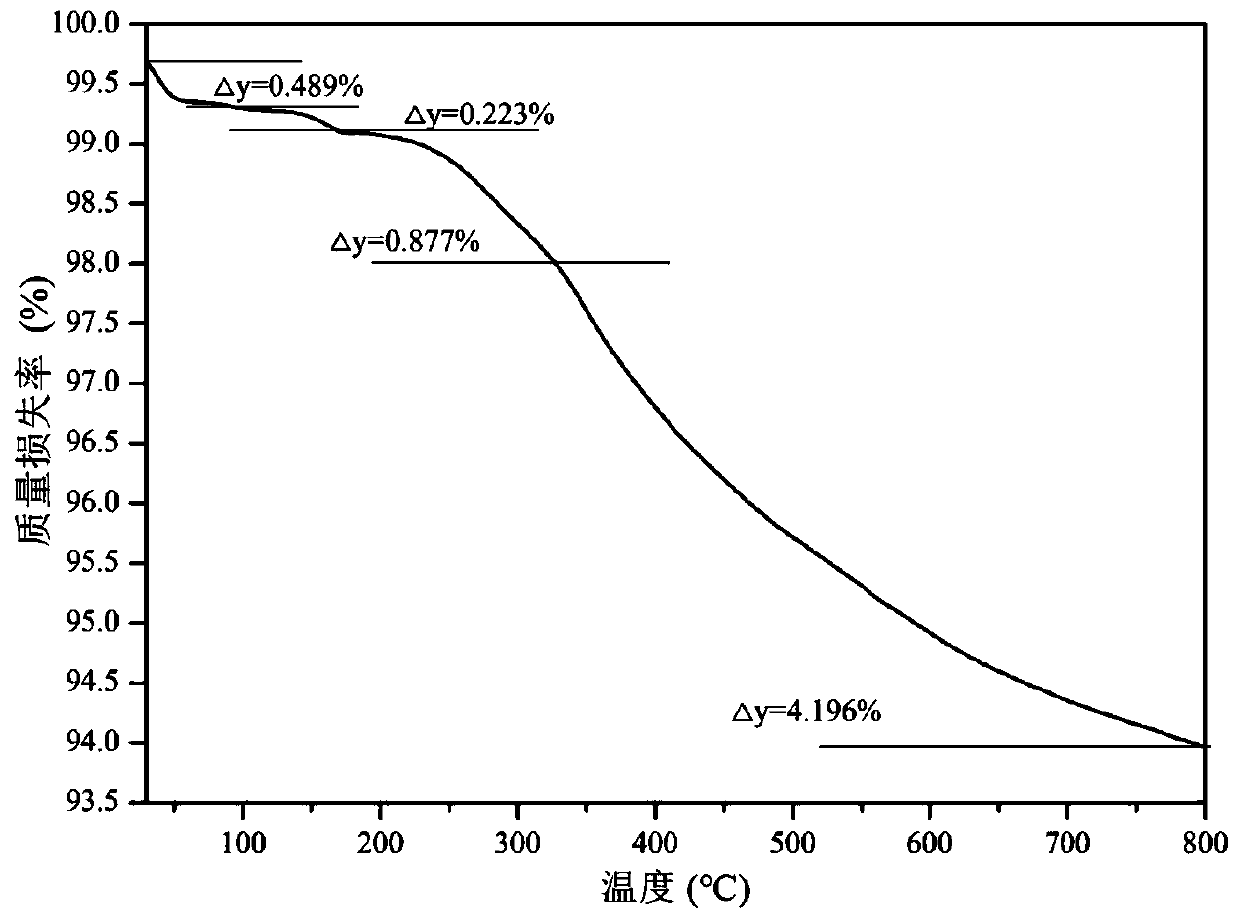

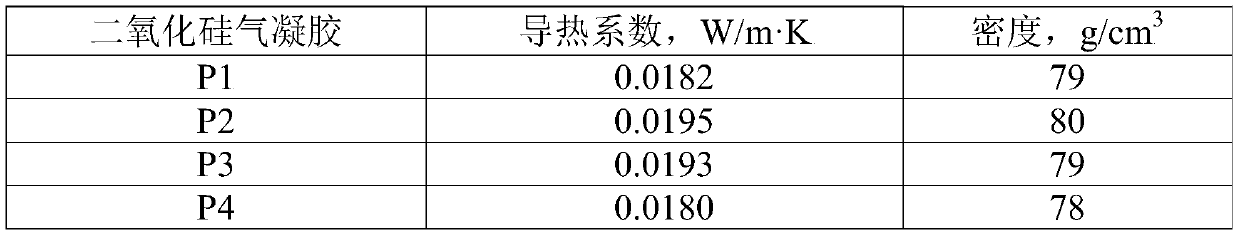

[0108] The silicon source precursor A methyl orthosilicate and the silicon source precursor B methyltrimethoxysilane (R1 is methyl, R2 is methoxy, n=1, m=3), methanol and water by mass ratio =1:2.5:60:1.5 Stir and mix to prepare a premixed solution; add 25% ammonia water to the premixed solution at 2 / 10,000 of the total mass of the premixed solution, stir evenly to prepare a gel solution; react for 1h , after waiting for the gel to complete, place the gel block in an environment of 50°C for 24 hours; then place the gel block in a drying kettle, 2 Use a pump to enter the drying kettle to keep the supercritical temperature of the drying kettle at 65°C and the pressure at 17MPa; CO 2 The flow rate through the supercritical drying tank is 2500 L / h, and the drying time is 24 hours to obtain silica airgel P1. After testing, the specific surface area of silica airgel P1 is 1070.7m 3 / g, and its thermal conductivity is shown in Table 1.

Embodiment 2

[0110] Prepare silica airgel according to the method of Example 1, the difference is: the silicon source precursor B methyltrimethoxysilane (R1 is methyl, R2 is methoxy, n=1, m=3) Replaced with silicon source precursor B dimethyldiethoxysilane (R 1 is methyl, R 2 is ethoxy, n=2, m=2). Silica airgel P2 was prepared. After testing, the thermal conductivity of the silica airgel P2 is shown in Table 1.

Embodiment 3

[0112] Silica airgel was prepared according to the method of Example 1, except that the silicon source precursor A, methyl orthosilicate, was replaced by ethyl orthosilicate. Silica airgel P3 was prepared. After testing, the thermal conductivity of the silica airgel P3 is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com