Hydrophilic modified silica sol and application thereof in preparation for hydrophilic anti-fog wear-resistant coating

A technology of hydrophilic modification and wear-resistant coating, which is applied in the direction of coating, etc., and can solve the problems of reduced surface hydrophilicity and anti-fog performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 5g of propyltriethoxysilane isocyanate, 5g of polyethylene glycol 200, 0.01g of dibutyltin dilaurate and 100mL of tetrahydrofuran into a 150mL three-necked bottle, and stir for 5 hours. The solvent was distilled off under reduced pressure to obtain a polyethylene glycol 200 modified silane coupling agent monomer.

[0027] At room temperature, dissolve 3g of silane coupling agent monomer modified by polyethylene glycol 200, 1g of tetraethyl orthosilicate, 0.01g of acetic acid and 0.1g of water in 10mL of ethylene glycol monoethyl ether, stir for 24 hours, and then let stand After 72 hours, a hydrophilic modified silica sol solution was obtained, with a mass of 13.4 g. The mass ratio of the prepared hydrophilic modified silica sol A to B is 3:1.

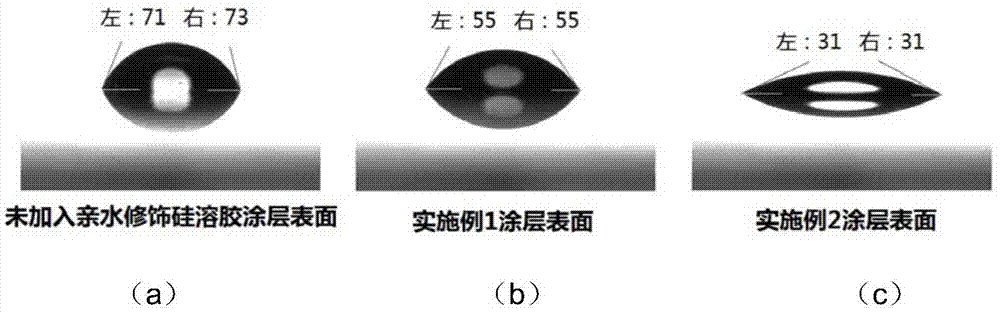

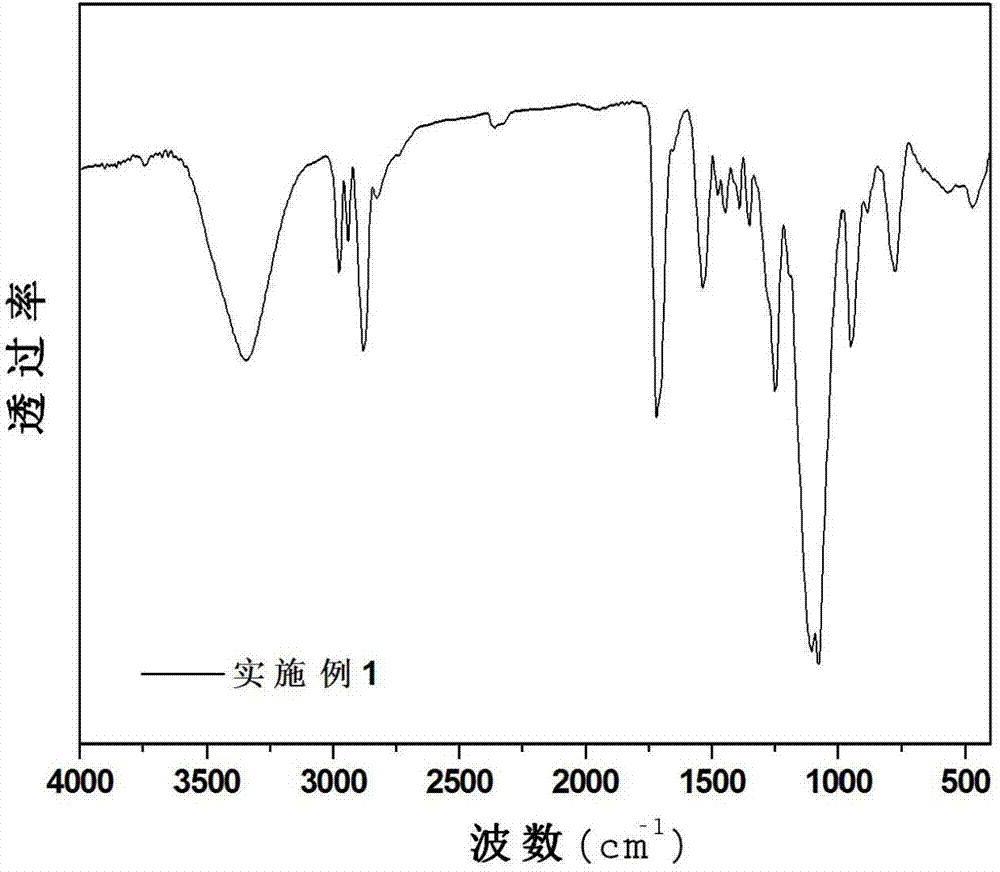

[0028] The infrared spectrogram of the hydrophilic modified silica sol prepared in embodiment 1 is shown in figure 1 , at 1720cm -1 The characteristic peak of the ester group appeared at 2885cm -1 The characteristic peak...

Embodiment 2

[0034] Add 5g of propyltriethoxysilane isocyanate, 5g of polyethylene glycol 800, 0.01g of dibutyltin dilaurate and 100mL of tetrahydrofuran into a 150mL three-necked bottle, and stir for 5 hours. The solvent was distilled off under reduced pressure to obtain a polyethylene glycol 800-modified silane coupling agent monomer.

[0035] At room temperature, dissolve 3 g of polyethylene glycol 800 modified silane coupling agent monomer, 1 g of tetraethyl orthosilicate, 0.01 g of acetic acid and 0.1 g of water in 10 mL of ethylene glycol monoethyl ether, and stir for 24 hours. After the stirring was stopped, the system was allowed to stand and age for 72 hours to obtain a hydrophilic modified silica sol solution with a mass of 13.4 g. The mass ratio of the hydrophilic modified silica sol A and B prepared in Example 2 is 3:1.

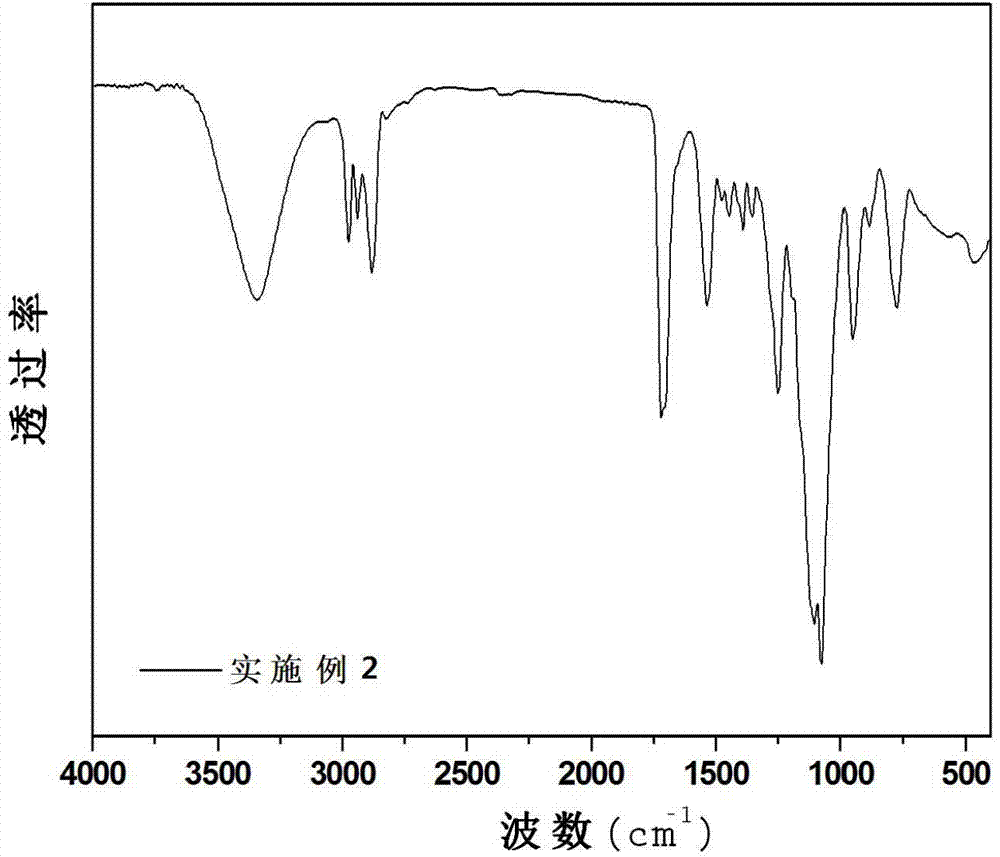

[0036] The infrared spectrogram of the hydrophilic modified silica sol prepared in embodiment 2 is shown in figure 2 , at 1720cm -1 The characteristic pea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com