Preparation method of organic-inorganic composite sol for metal aluminum sheet surface corrosion prevention

A composite sol and metal aluminum technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of further improvement in adhesion and hardness, and achieve the effects of improving corrosion resistance, increasing adhesion, and enhancing coating hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

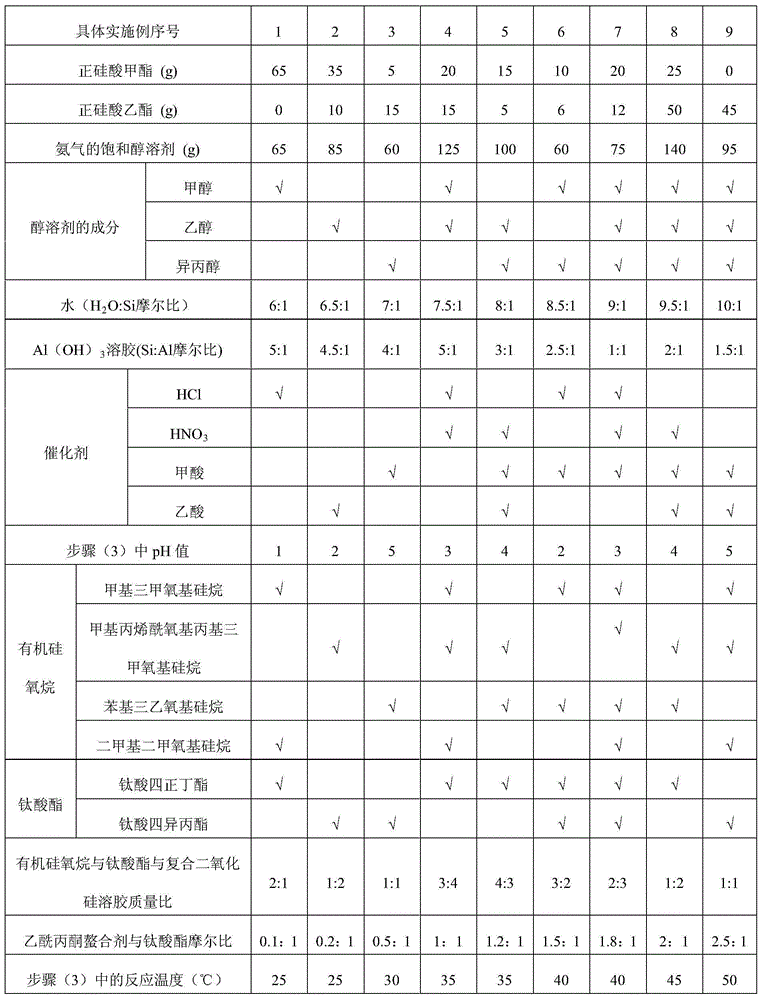

[0014] The present invention is further described by examples below.

[0015] The preparation method of the organic-inorganic composite sol for anticorrosion on the surface of metal aluminum plate in the present invention includes the following steps:

[0016] (1) Under the stirring condition of 300r / min, add one or a mixture of methyl orthosilicate and ethyl orthosilicate to the saturated alcohol solvent of ammonia gas at a mass ratio of 1:1~5 ; Then add water to ensure that the molar ratio of water to silicon is 6-10:1; after reacting at 60°C for 8 hours, heating at 90°C to reflux for 8 hours to remove ammonia, and obtaining particle-type nano silica sol by rotary evaporation;

[0017] (2) Add Al(OH) to the nano silica sol at a stirring rate of 800r / min 3 Sol, keep the molar ratio of Si:Al at 5~1:1; after aging at 50℃ for 24 hours, Al(OH) is obtained 3 In-situ modified coated composite silica sol;

[0018] (3) Under the stirring condition of 300r / min, add a catalyst to the composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com