Method for preparing aerogel composite material by using tetramethyl orthosilicate

A technology of methyl orthosilicate and composite materials, applied in the directions of silicon oxide, silicon dioxide, etc., can solve problems such as unfavorable environmental protection, complicated preparation process, complicated preparation process, etc., to avoid the occurrence of gel and simple preparation process. , the effect of inhibiting the gel reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

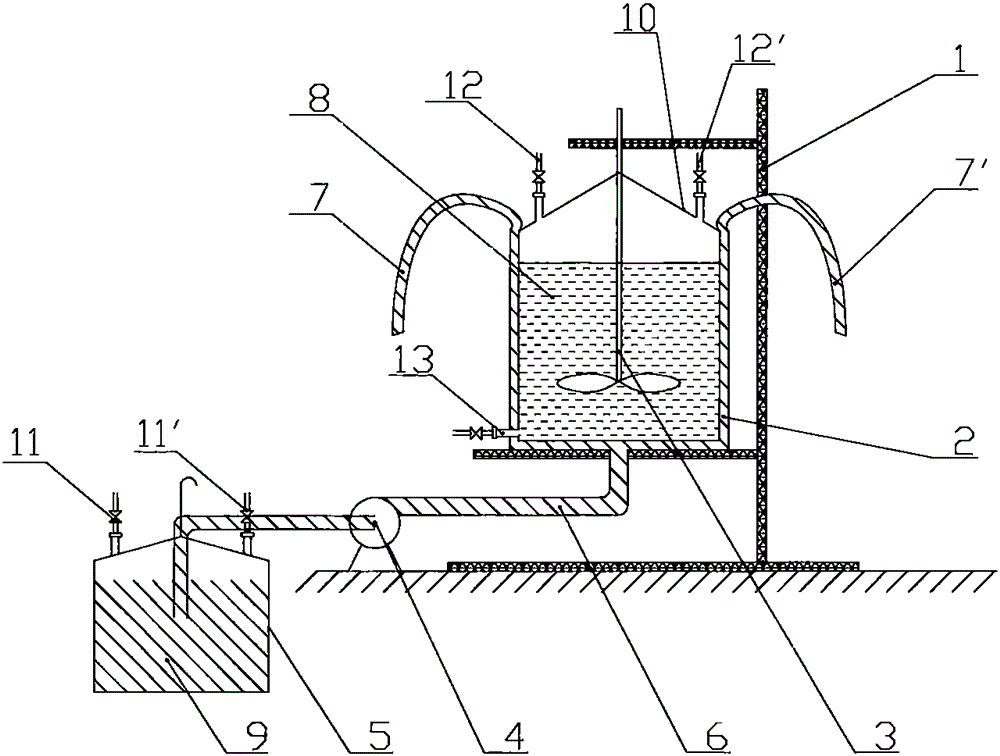

[0061] (1) Preparation of sol: first pour methyl orthosilicate and water in proportion as attached figure 1 Shown in the reaction-circulation cooling equipment, fully stirred, then add alcohol solvent to the system, continue to stir, to obtain silica sol;

[0062] (2) sol dipping: immersing the fiber material in the sol;

[0063] (3) Stand still: put the fiber material / sol system in a low temperature environment from -40°C to 0°C;

[0064] (4) Gel: the fiber material / sol system is taken out from the low temperature environment, and gelled at room temperature or under heating conditions to obtain a silica wet gel;

[0065] (5) Aging: aging at room temperature or under heating for 8 hours to 168 hours;

[0066] (6) Solvent replacement: put the aged wet gel material into an alcohol solvent or a ketone solvent so that the water content is lower than 1%;

[0067] (7) Surface treatment: soak the wet gel that has completed the solvent replacement with a hydrophobizing agent;

[0...

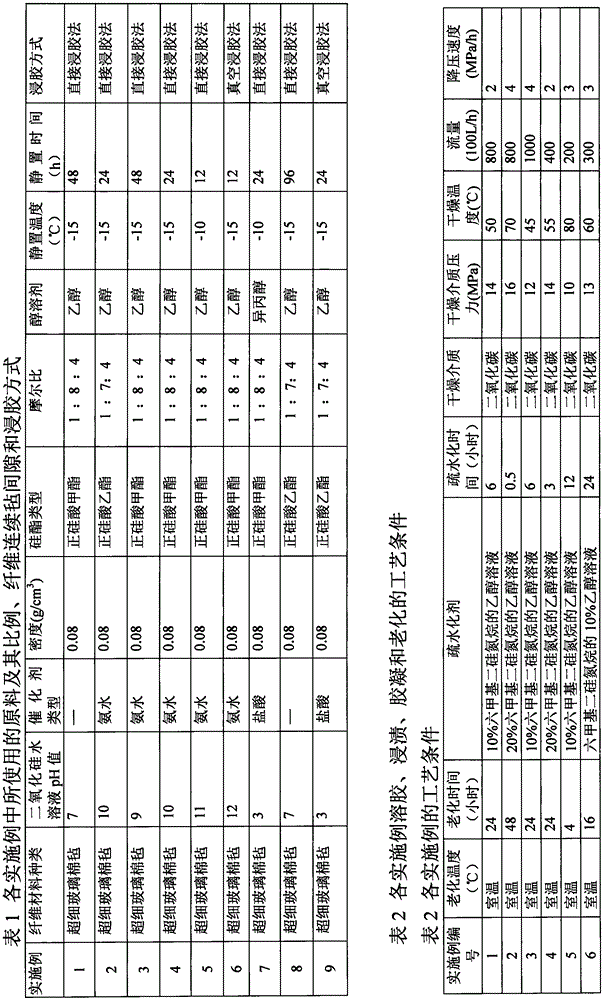

Embodiment 1

[0096] Add orthosilicate methyl ester, deionized water and absolute ethanol into the reaction-circulation cooling equipment and mix well to prepare silica sol, and the cooling temperature is -15°C. The molar ratio of methyl orthosilicate, deionized water and alcohol solvent is 1:8:4.

[0097]Impregnate glass fiber wool with the prepared silica sol, and the impregnation method adopts the method (a) described herein to carry out, that is, directly add silica sol to the mold cavity that is equipped with glass fiber wool with a bulk density of 0.08 g / cubic centimeter (consisting of No. 45 steel, and the inner surface of the cavity is coated with anti-corrosion coating polytetrafluoroethylene), rely on gravity impregnation; then, let it stand at -15°C for 48 hours, take it out, and put it at a gel temperature of 25°C A fibrous gel was obtained in 24 hours. After aging for 48 hours in ethanol as a solvent at a temperature of 25° C., surface treatment was carried out for 6 hours wit...

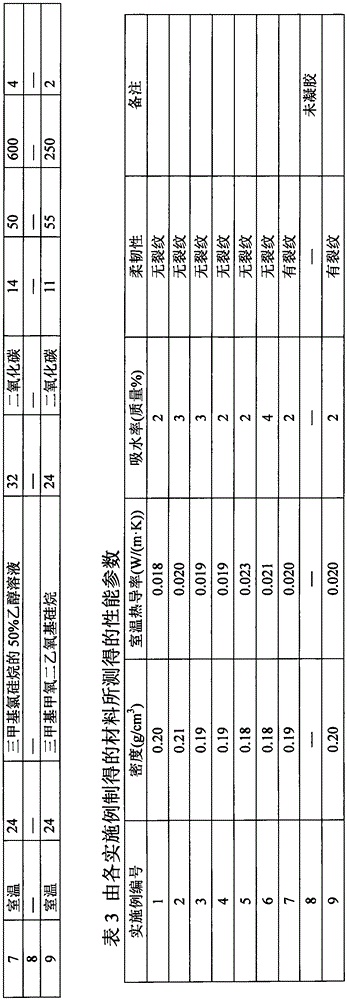

Embodiment 2 to 9

[0099] Examples 2 to 9 were carried out in the same manner as in Example 1 except for the contents and notes shown in Tables 1, 2 and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com