Carbon dioxide adsorbent based on hierarchical porous silicon dioxide block body and preparation method of carbon dioxide adsorbent

A hierarchical porous, silica technology, applied in the field of materials, can solve problems such as difficulty in recycling and reuse, and achieve the effects of good recycling performance, carbon dioxide adsorption and recycling performance, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

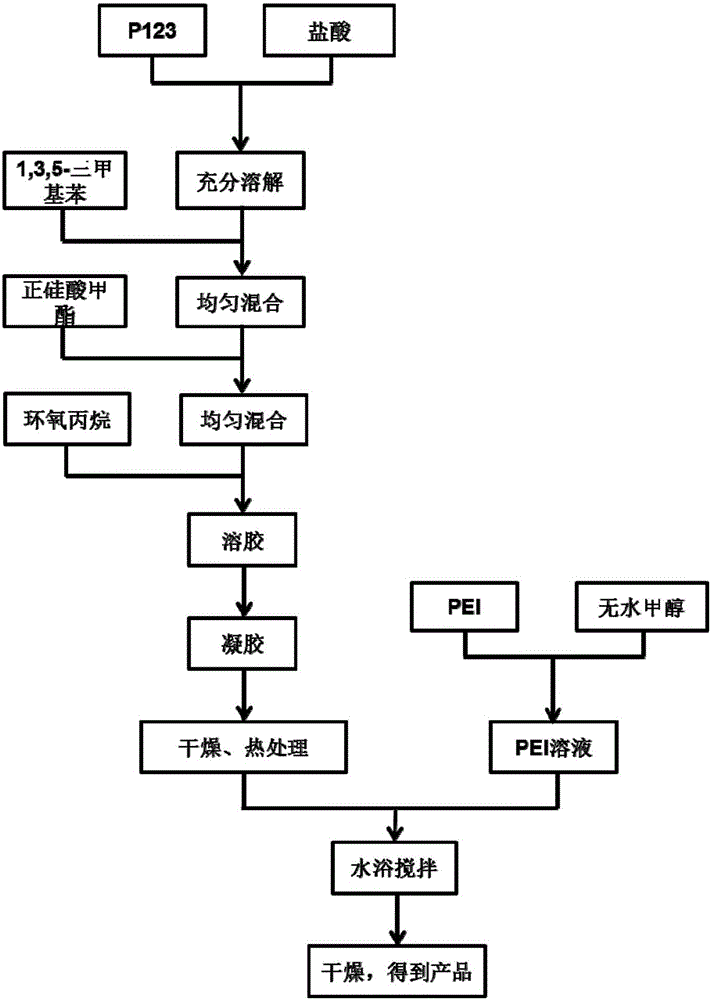

[0039] Embodiment 1, a preparation method of hierarchical porous silica block:

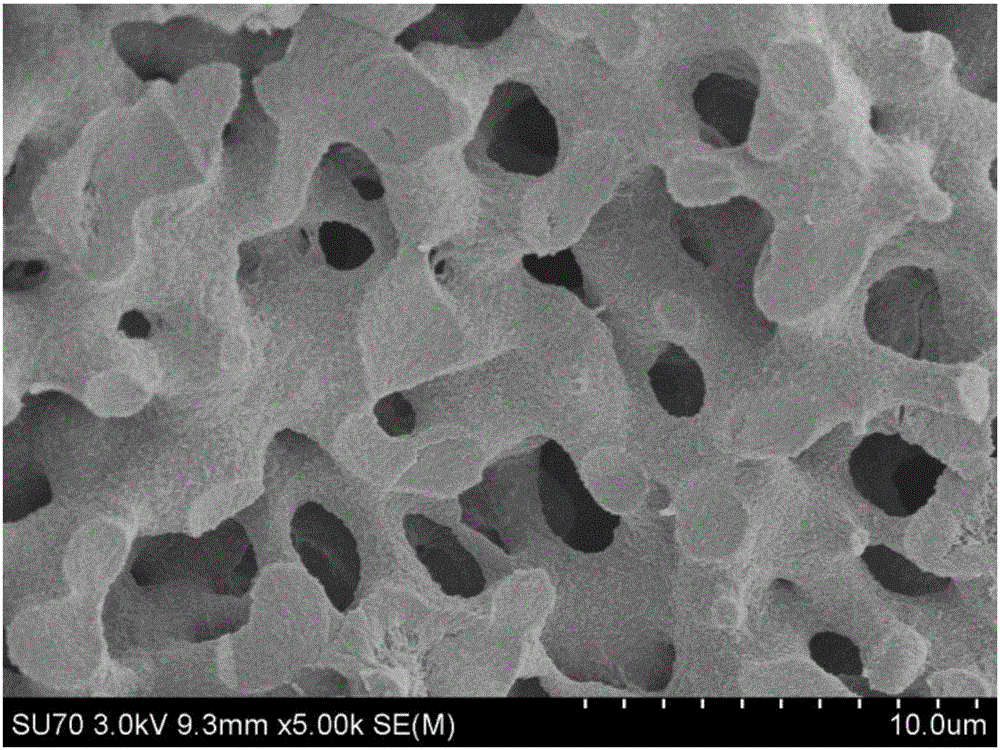

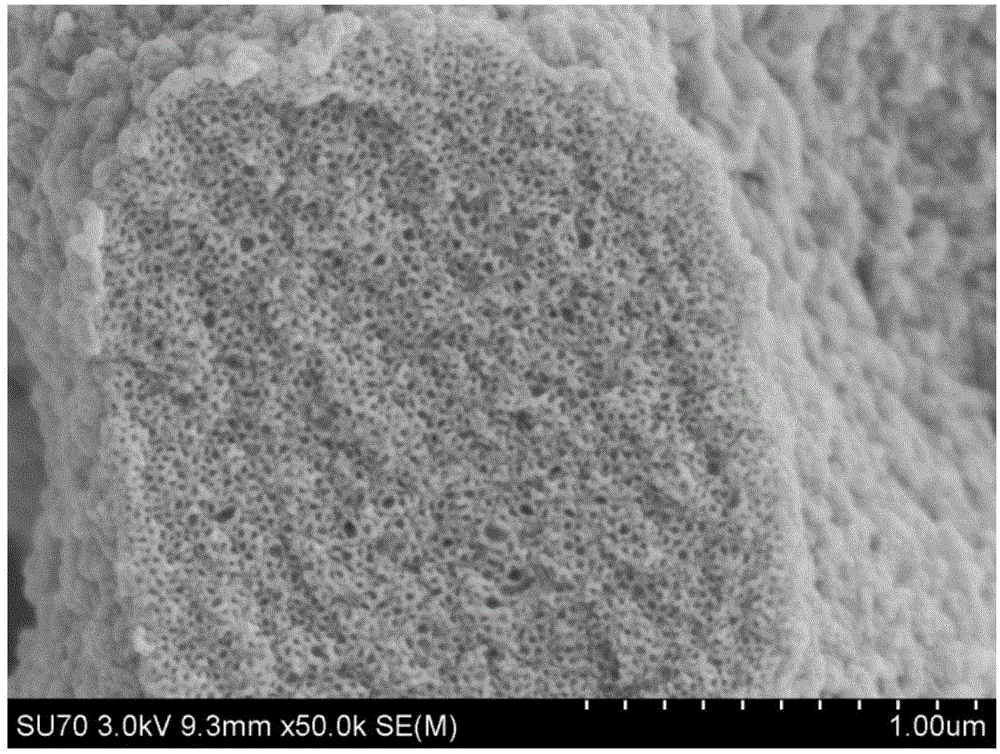

[0040] Weigh 7g P123 and add to 0.01mol·L -1 In 28.8ml of hydrochloric acid solution, stir magnetically for 5 hours under ice bath conditions to completely dissolve P123; then slowly add 4ml of 1,3,5-trimethylbenzene dropwise (dropping time is 30 minutes), under ice bath conditions Fully stir for 3 hours; then add 12ml of methyl orthosilicate, fully stir for 3 hours under ice bath conditions; then slowly add dropwise (dropping time is 30 minutes) 5.5ml propylene oxide, fully stir for 5min under ice bath conditions, Obtain a sol (transparent sol); place the sol in an oven at 40±5°C for 36 hours, and dry the resulting gel (translucent gel) in an oven at 60±5°C for 4 days (the purpose is to completely evaporate the water) , put the obtained block (white block) into the muffle furnace in air at 2°C·min -1 The temperature was raised to 550°C at a high speed, and kept for 5 hours, and then cooled to r...

Embodiment 2

[0041] Example 2, a preparation method of a carbon dioxide adsorbent based on hierarchical porous silica blocks:

[0042]Weigh 5.72g of PEI (polyethyleneimine) and dissolve it in 15ml of methanol to prepare a PEI solution, add 8.58g of the hierarchical porous silica block obtained in Example 1, stir for 3 hours at 40±5°C in a water bath, and then place Dry in an oven (dry in an oven at 80±10° C. for 2 days) to obtain a hierarchical porous silica block with a PEI loading of 40%, which is a carbon dioxide adsorbent based on a hierarchical porous silica block as a product. After testing, the product has good carbon dioxide adsorption and cycle performance.

Embodiment 3

[0043] Example 3, a preparation method of a carbon dioxide adsorbent based on hierarchical porous silica blocks:

[0044] Weigh 6.54g of PEI and dissolve it in 15ml of methanol to prepare a PEI solution, add 6.54g of the hierarchical porous silica block obtained in Example 1, stir for 3 hours at 40±5°C in a water bath, and then place it in an oven to dry (80 ±10°C oven for 2 days) to obtain a hierarchical porous silica block with a PEI loading of 50%, which is a carbon dioxide adsorbent based on the hierarchical porous silica block as a product. After testing, the product has good carbon dioxide adsorption and cycle performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com