Preparation method of porous mullite block

A technology for porous mullite and block, which is applied in the field of preparation of porous mullite blocks, can solve problems such as difficult control, complicated processes such as co-hydrolysis sol-gel transition and phase separation, and achieves low equipment cost and low process technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, a kind of preparation method of porous mullite block body, with 2g aluminum chloride hexahydrate (AlCl 3 ·6H 2 O) as aluminum source, 0.2805 mL of orthomethyl silicate (TMOS) as silicon source, 1.8 mL of propylene oxide (PO) as gel accelerator, 0.025 g of polyethylene oxide (PEO, average molecular weight 1×10 6 ) is a phase separation inducer; the following steps are carried out in sequence:

[0021] 1), first 2g aluminum chloride hexahydrate (AlCl 3 ·6H 2 O) and 0.025g of polyethylene oxide (PEO) were dissolved in a solvent consisting of 2.1mL of ethanol and 2mL of deionized water, and then 0.2805mL of orthomethyl silicate (TMOS) was added dropwise under stirring; 1 minute dropwise After finishing, continue stirring reaction 60min; Reaction temperature is room temperature;

[0022] 2) At room temperature, quickly add 1.8mL propylene oxide (PO) to the product obtained in step 1) (a transparent and clear solution), and stir evenly for 1 minute to obtai...

Embodiment 2

[0027] Embodiment 2, a kind of preparation method of porous mullite block,

[0028] Change the heat treatment temperature in Step 5) of Example 1 from 800°C to 1100°C, and the rest are the same as in Example 1.

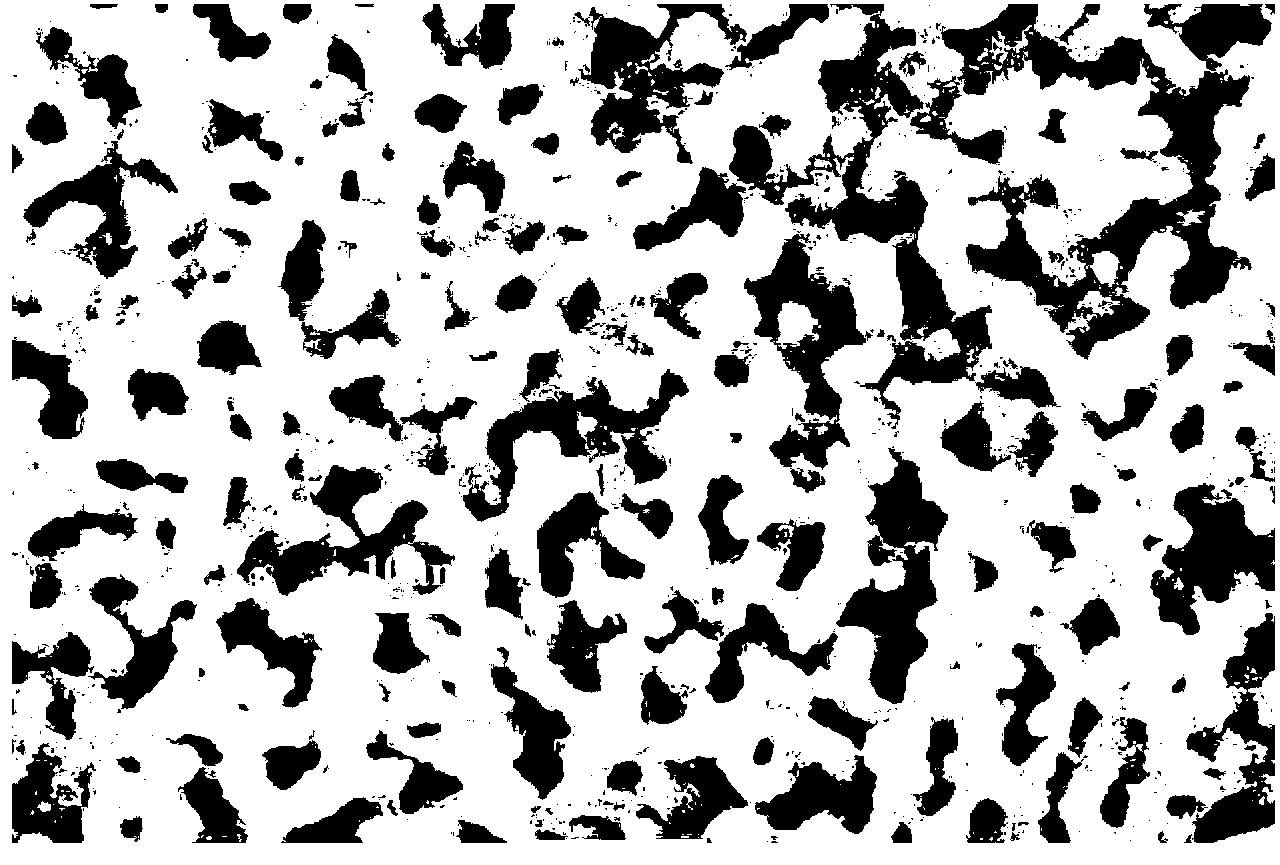

[0029] The prepared porous mullite block crystallizes well and completely, and has a co-continuous macroscopic through-pore structure and a complete framework (see figure 1 ), while the framework consists of disc-like or needle-like nanocrystalline particles. Its pore size distribution is concentrated, and its bulk density is about 1.34 g cm -3 , the calculated relative density is 42%. The N of the porous mullite block 2 The adsorption-desorption curve is H3 type, indicating that the block has slit-like mesopores due to its skeleton structure, and the mesopores almost disappear. The average pore size of the macropores is 1.2 μm, and the specific surface area is 54 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com