Water-based acrylic silver powder paint suitable for mechanical equipment and preparation method thereof

A technology of acrylic silver powder and mechanical equipment, applied in the direction of metal-free paint, coating, polyurea/polyurethane coating, etc., can solve the problems of poor adhesion, great harm to human body, poor hiding power, etc., and achieve good water resistance And salt spray resistance, good physical properties and chemical resistance, good physical properties and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

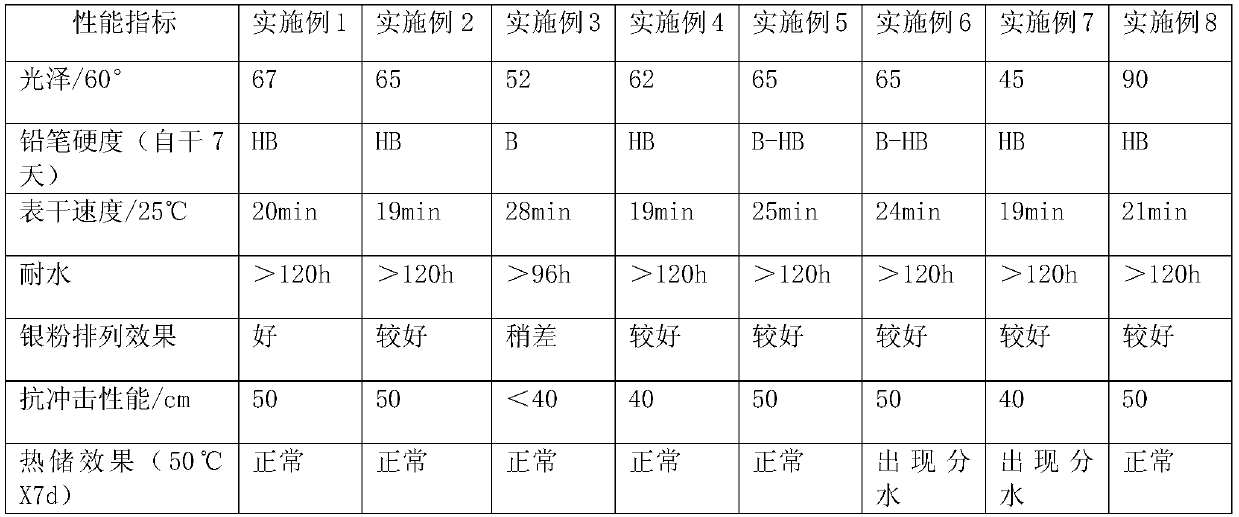

Examples

Embodiment 1

[0043] A water-based acrylic silver powder paint suitable for mechanical equipment, in parts by mass, 60 parts of water-based self-crosslinking acrylic emulsion with a TG value of 26°C and a pH value of 7.5, a water-based paint with a solid content of 30% and a pH value of 7.0 5 parts of polyurethane emulsion, 3 parts of co-solvent, 3 parts of film-forming aid, 0.2 part of anti-settling agent, 3 parts of aluminum silver paste, 0.5 part of anti-flash rust agent, 0.2 part of thickener, 20 parts of deionized water, conventional auxiliary 3.5 parts of additives (conventional additives are 1 part of dispersant, 0.3 parts of defoamer, 0.3 parts of amine neutralizer, 0.2 parts of wetting agent, 0.2 parts of leveling agent, 1.5 parts of silver powder alignment assistant);

[0044]In this technical solution, the film-forming aids are BCS and DPNB in a ratio of 2:1; the anti-settling agent is a polyurea anti-settling agent; the anti-flash rust agent is nitrite; The thickener is an ass...

Embodiment 2

[0056] A water-based acrylic silver powder paint suitable for mechanical equipment, in parts by mass, 60 parts of water-based self-crosslinking acrylic emulsion with a TG value of 26°C and a pH value of 7.5, a water-based paint with a solid content of 30% and a pH value of 7.0 5 parts of polyurethane emulsion, 3 parts of co-solvent, 3 parts of film-forming aid, 0.2 part of anti-settling agent, 3 parts of aluminum silver paste, 0.5 part of anti-flash rust agent, 0.2 part of thickener, 20 parts of deionized water, conventional auxiliary 3.4 parts of additives (conventional additives are 1 part of dispersant, 0.3 parts of defoamer, 0.2 parts of amine neutralizer, 0.2 parts of wetting agent, 0.2 parts of leveling agent, 1.5 parts of silver powder alignment assistant);

[0057] In this technical solution, the film-forming aids are BCS and DPNB, and the matching ratio is 2:1; the anti-settling agent is a polyurea anti-settling agent, and the anti-flash rust agent is nitrite; The thi...

Embodiment 3

[0069] A water-based acrylic silver powder paint suitable for mechanical equipment, in parts by mass, 60 parts of water-based acrylic emulsion (commercially available common acrylic emulsion) with a TG value of 20°C and a pH value of 7.5, with a solid content of 30% , 5 parts of water-based polyurethane emulsion with a pH value of 7.0, 3 parts of cosolvent, 3 parts of film-forming aid, 0.2 part of anti-settling agent, 3 parts of aluminum silver paste, 0.5 part of anti-flash rust agent, 0.2 part of thickener, 20 parts of ionized water, 3.4 parts of conventional additives (conventional additives are 1 part of dispersant, 0.3 parts of defoamer, 0.2 parts of wetting agent, 0.2 parts of leveling agent, 1.5 parts of silver powder alignment aid, amine neutralizer 0.2 copies);

[0070] In this technical solution, the film-forming aids are BCS and DPNB in a ratio of 2:1; the anti-settling agent is a polyurea anti-settling agent; the anti-flash rust agent is nitrite; The thickener is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com