Plastic-removed food paper and preparation method thereof

A technology of food paper and chemical pulp, applied in the field of paper products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

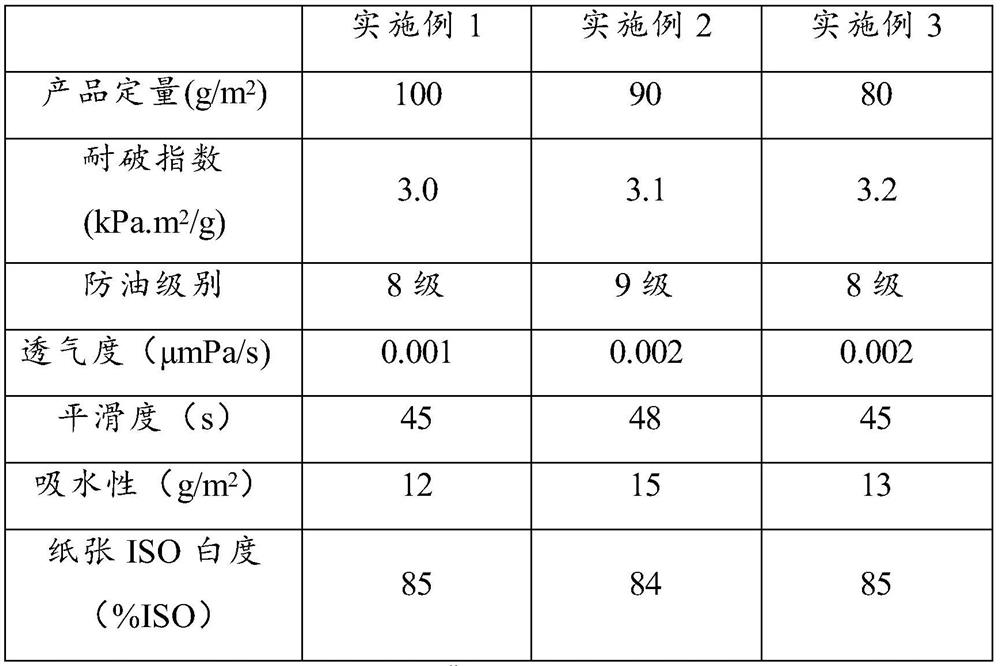

Examples

preparation example Construction

[0020] The invention provides a method for preparing plastic-free food paper, comprising:

[0021] Mix bleached kraft softwood chemical pulp and bleached kraft hardwood chemical pulp, go through thick stock screening, seasoning, pulp flushing, desanding and degassing, sizing, mixing with ASA, and fine sieving to obtain pretreated pulp;

[0022] The pretreated pulp goes through the headbox, wire dehydration forming, pressing, first drying, first surface sizing, second drying, second surface sizing, third drying, calendering, coiling ,production;

[0023] The first surface sizing is: surface sizing with acrylic emulsion; the second surface sizing is: surface sizing with polydimethylsiloxane.

[0024] In the preparation method of plastic-free food paper provided by the invention, firstly, bleached kraft softwood chemical pulp and bleached kraft hardwood chemical pulp are mixed.

[0025] The present invention does not limit the sources of the bleached kraft softwood chemical pul...

Embodiment 1

[0067] The pulp ratio is bleached kraft softwood chemical pulp (NBKP) and bleached kraft hardwood chemical pulp (LBKP). The weight ratio of the slurry is: NBKP35%; LBKP65%. ASA is used for sizing, the amount of ASA is 0.8kg / t paper, and the adding point is the screen inlet of the paper machine. The first surface sizing uses acrylic emulsion for surface sizing, the acrylic emulsion uses a solid content of 30%, and the amount of sizing is controlled at 5g / m 2 . The second surface sizing uses polydimethylsiloxane for surface sizing. The solid content of polydimethylsiloxane is 9%, and the amount of sizing is controlled at 0.6g / m 2 .

[0068] After the above two kinds of pulp are mixed, the mixed pulp is adjusted to a concentration of 3.0%, and it is subjected to thick pulp sieving, seasoning, punching, desanding and degassing, sizing, fine sieving, dehydration forming at the wire part, pressing, first drying, The first surface sizing, the second drying, the second surface siz...

Embodiment 2

[0072] The pulp ratio is bleached kraft softwood chemical pulp (NBKP) and bleached kraft hardwood chemical pulp (LBKP). The weight proportion of slurry is: NBKP31%; LBKP69%. ASA is used for sizing, the amount of ASA is 1.1kg / t paper, and the adding point is the screen inlet of the paper machine. The first surface sizing uses acrylic emulsion for surface sizing. The solid content of the acrylic emulsion is 35%, and the amount of sizing is controlled at 5.5g / m2. The second surface sizing uses polydimethylsiloxane for surface sizing. The solid content of polydimethylsiloxane is 8%, and the amount of sizing is controlled at 0.5g / m 2 .

[0073] After the above two kinds of slurry are mixed, the mixed slurry is adjusted to a concentration of 2.9%. After thickening, seasoning, pulping, desanding and degassing, sizing, fine sieving, dehydration forming at the wire part, pressing, first drying, The first surface sizing, the second drying, the second surface sizing, the third drying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com