Method for preparing irregular sulfonated poly aromatic (sulfur) ether with high efficiency

A technology for sulfonating polyaromatic sulfide and polyaromatic ether, which is applied in the field of novel and efficient preparation of random sulfonated polyaromatic ether, can solve the problems of complicated recovery process, large volume of reaction solution, long reaction time, etc., and achieves simplification Equipment composition, simplified process, high molecular weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

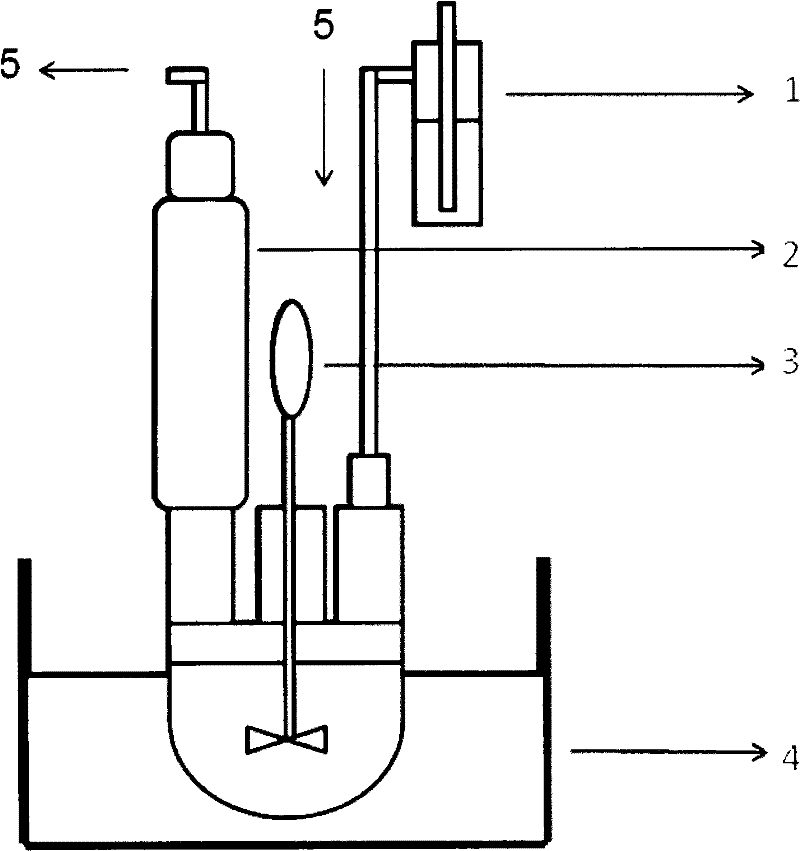

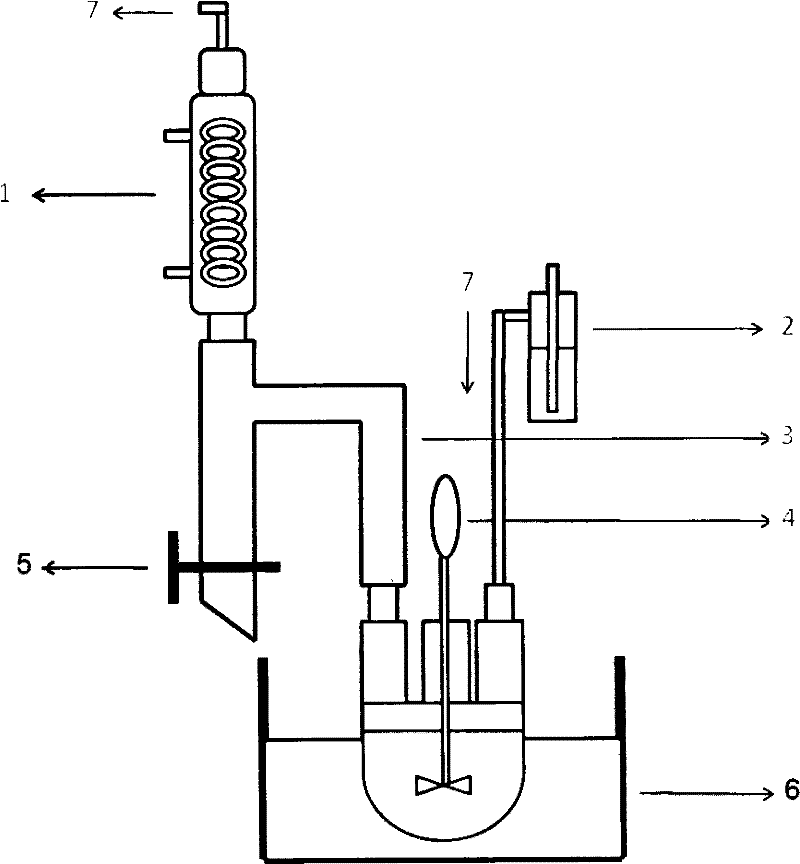

Embodiment 1

[0055] according to figure 2 In the shown reaction device, 3,3'-sodium disulfonate-4,4'-dichlorodiphenylsulfone (SDCDPS, 17.1938g, 35mmol), 4,4'-dichlorodiphenylsulfone (DCDPS, 18.6654 g, 65mmol), 4,4'-biphenol (BP, 18.6210g, 100mmol), anhydrous potassium carbonate (K 2 CO 3 , 27.6420g, 200mmol), 272mL N,N-dimethylacetamide (DMAc) were mixed, the reaction temperature was raised to 180°C, and the reaction was carried out for 12 hours. Stop heating and stirring, and cool to room temperature naturally. The reaction solution was slowly poured into 2L of deionized water to obtain a white fibrous polymer, soaked in 4L of deionized water for 8 hours at 80°C, repeated three times, filtered, dried, and then vacuum-dried at 100°C for 24 hours to obtain a shallow Yellow fibrous polymer (sulfonated polyethersulfone compound), 46.7 g, yield: 99%, intrinsic viscosity: 0.91 dL / g.

Embodiment 2

[0057] according to figure 2 In the shown reaction device, 3,3'-sodium disulfonate-4,4'-dichlorodiphenylsulfone (SDCDPS, 17.1938g, 35mmol), 4,4'-dichlorodiphenylsulfone (DCDPS, 18.6654 g, 65mmol), 4,4'-biphenol (BP, 18.6210g, 100mmol), anhydrous potassium carbonate (K 2 CO 3 , 27.6420g, 200mmol), 272mL of N-methylpyrrolidone (NMP) were mixed, the reaction temperature was raised to 190°C, and the reaction was carried out for 12 hours. Stop heating and stirring, and cool to room temperature naturally. The reaction solution was slowly poured into 2L of deionized water to obtain a light yellow fibrous polymer, soaked in 4L of deionized water at 80°C for 8 hours, repeated three times, filtered, dried, and then vacuum-dried at 100°C for 24 hours to obtain Yellow fibrous polymer (sulfonated polyethersulfone compound), 44.3 g, yield: 94%, intrinsic viscosity: 0.89 dL / g.

Embodiment 3

[0059] according to figure 2 In the shown reaction device, 3,3'-sodium disulfonate-4,4'-dichlorodiphenylsulfone (SDCDPS, 17.1938g, 35mmol), 4,4'-dichlorodiphenylsulfone (DCDPS, 18.6654 g, 65mmol), 4,4'-biphenol (BP, 18.6210g, 100mmol), anhydrous potassium carbonate (K 2 CO 3 , 27.6420g, 200mmol), 272mL N,N-dimethylacetamide (DMAc) were mixed, the reaction temperature was raised to 180°C, and the reaction was carried out for 24 hours. Stop heating and stirring, and cool to room temperature naturally. The reaction solution was slowly poured into 2L of deionized water to obtain a white fibrous polymer, soaked in 4L of deionized water for 8 hours at 80°C, repeated three times, filtered, dried, and then vacuum-dried at 100°C for 24 hours to obtain a shallow Yellow fibrous polymer (sulfonated polyethersulfone compound), 46.7 g, yield: 99%, intrinsic viscosity: 1.04 dL / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com