Soil stabilizer prepared from bauxite dressing tailings

A soil stabilizer, bauxite technology, applied in soil conditioning materials, applications, chemical instruments and methods, etc., can solve the problems of easily generating sand, contrary to the concept of ecological environmental protection, consuming large energy, etc. Water erosion ability, good economy and environmental protection, the effect of ensuring film forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

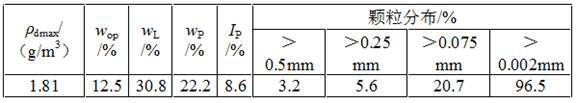

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of 1# bauxite dressing tailings-based soil curing agent

[0031] Powder components: Dry the three raw materials of bauxite tailings, lime and steel slag respectively to make the moisture content less than 0.5%, and then grind to a fineness of more than 300 mesh; After weighing 30% of lime and 10% of steel slag by weight, the components are mixed evenly to obtain the bauxite tailings-based soil curing agent powder component; the powder dosage is 4% of the base soil.

[0032] Liquid component: polyvinyl alcohol uses polyvinyl alcohol 17-92, the relative molecular weight of polyethylene glycol is 2000-4000, and the mixture of polyvinyl alcohol and polyethylene glycol is added to the temperature above 95 ℃ according to the mass ratio of 20:1. In hot water, the mass ratio of the mixture to water is 1:100, so that it can be fully dissolved to obtain a transparent and uniform liquid component without impurity particles. After cooling to room temperature, ...

Embodiment 2

[0033] Example 2 Preparation of 2# bauxite dressing tailings-based soil curing agent

[0034] Powder components: Dry the three raw materials of bauxite dressing tailings, slaked lime and slag powder respectively, so that the moisture content is less than 0.5%, and then grind to a fineness of more than 300 mesh; , slaked lime 20%, and slag powder 40% by weight, and then mix the components evenly to obtain the bauxite beneficiation tailings-based soil curing agent powder component; the powder dosage is 4% of the base soil .

[0035] Liquid component: polyvinyl alcohol uses polyvinyl alcohol 17-92, the relative molecular weight of polyethylene glycol is 2000-4000, and the mixture of polyvinyl alcohol and polyethylene glycol is added to the temperature above 95 ℃ according to the mass ratio of 10:1. In hot water, the mass ratio of the mixture to water is 1:100, so that it can be fully dissolved to obtain a transparent and uniform liquid component without impurity particles. After...

Embodiment 3

[0036] Example 3 Preparation of 3# bauxite dressing tailings-based soil curing agent

[0037] Powder components: Dry the bauxite tailings, calcium carbide slag, and slag powder separately to make the moisture content less than 0.5%, grind to a fineness of more than 300 mesh, and use 20% of the bauxite tailings, calcium carbide slag After weighing 70% and 10% of slag powder by weight, mix each component evenly to obtain the bauxite dressing tailings-based soil curing agent powder component; the powder dosage is 4% of the base soil.

[0038]Liquid component: polyvinyl alcohol uses polyvinyl alcohol 17-92, the relative molecular weight of polyethylene glycol is 2000-4000, and the mixture of polyvinyl alcohol and polyethylene glycol is added to the temperature above 95 ℃ according to the mass ratio of 5:1. In hot water, the mass ratio of the mixture to water is 1:100 to fully dissolve to obtain a transparent and uniform liquid component without impurity particles, cool to room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com