Single-component water-based coating with high film forming performance and preparation method thereof

A technology of film-forming properties and water-based coatings, applied in the direction of coatings, etc., can solve the problems of low cross-linking density of water-based emulsions, long time required for film formation, and long construction period, so as to increase the cross-linking density, reduce the time used, The effect of increasing the solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of this one-component high-film-forming water-based coating is: mixing water, acrylic acid modified water-based polyurethane emulsion, calcium carbonate, white pigment, substrate wetting agent, wetting and dispersing agent and dispersing agent together; with 1400 Stir and disperse at a speed of -1600r / min (rpm) for 20-60min; after the dispersion is complete, add water-based amino resin emulsion, leveling agent, defoamer, thickener and film-forming aid, and then use 1400-1600r / min Stir and disperse at a high speed for 5-30 minutes; add a pH regulator to adjust the pH value to 7.5-8 as the case may be, to obtain the one-component water-based coating with high film-forming performance.

[0041] The acrylic acid modified water-based polyurethane emulsion has a solid content of 80%. The preparation method is: drop acrylic acid monomers into the water-based polyurethane resin, use acrylic acid as the seed emulsion, and synthesize the core-shell structure...

Embodiment 1

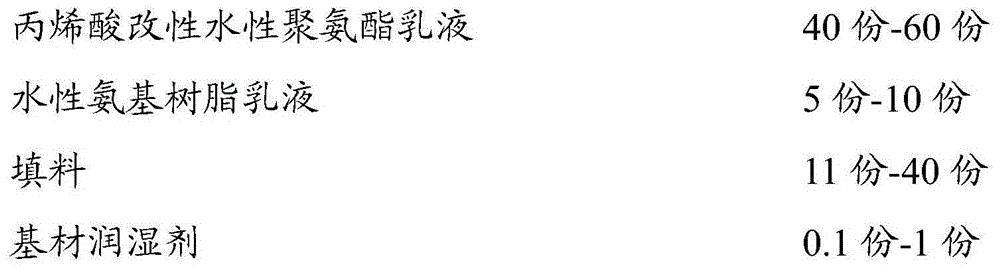

[0046] The one-component high film-forming performance water-based paint of the present invention comprises the following components by weight:

[0047]

[0048]The method for preparing the above-mentioned single-component high-film-forming water-based coating by using this formula is as follows: according to the content of each component in the above-mentioned formula, water, acrylic acid modified water-based polyurethane emulsion, titanium dioxide, talcum powder, calcium carbonate, and substrate Add the wetting agent, wetting and dispersing agent and dispersing agent into the mixing tank, and stir for 30 minutes at a speed of 1500r / min. After the dispersion is complete, add water-based amino resin emulsion, leveling agent, defoamer, thickener and Propylene glycol n-butyl ether and ethanol are mixed at a ratio of 5:1 as a film-forming aid, then stirred and dispersed at a speed of 1500r / min for 15 minutes, and finally added with a pH regulator to adjust the pH value to 7.5-8...

Embodiment 2

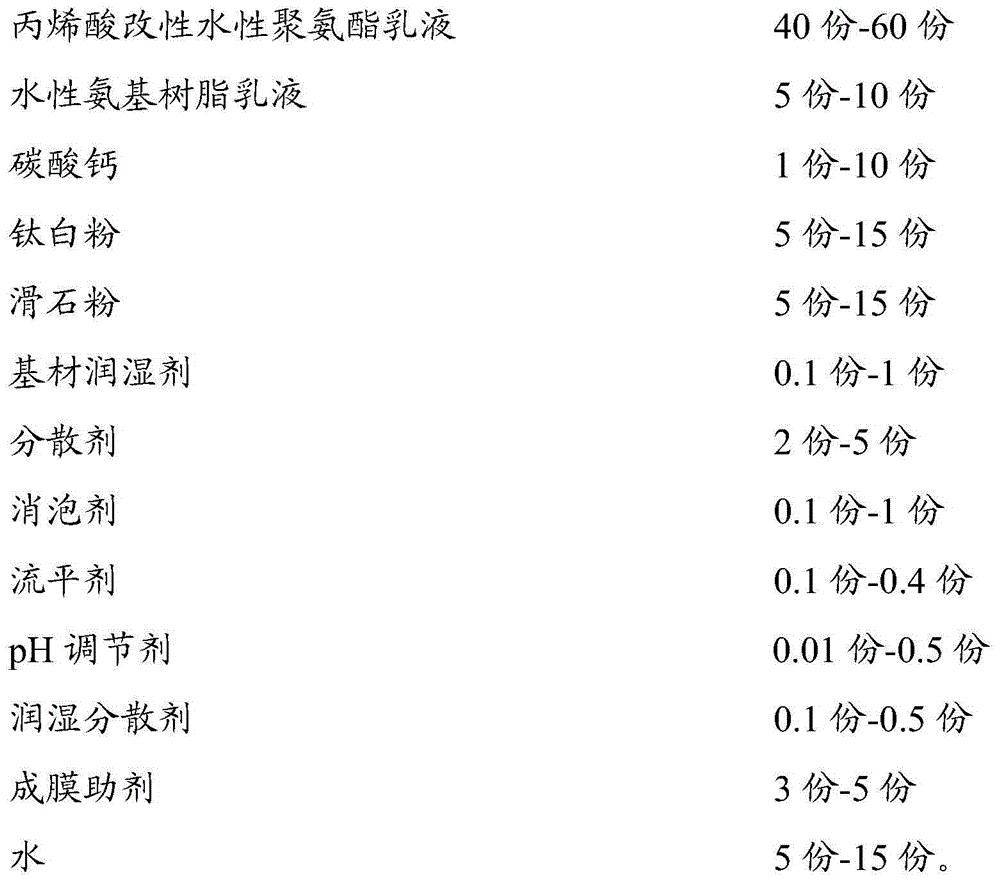

[0052] The one-component high film-forming performance water-based paint of the present invention comprises the following components by weight:

[0053]

[0054] The method for preparing the above-mentioned single-component high-film-forming water-based coating by using this formula is as follows: according to the content of each component in the above-mentioned formula, water, acrylic acid modified water-based polyurethane emulsion, titanium dioxide, talcum powder, calcium carbonate, and substrate Add the wetting agent, wetting and dispersing agent and dispersing agent into the mixing tank, and stir at a speed of 1400r / min for 60 minutes. After the dispersion is complete, add water-based amino resin emulsion, leveling agent, defoamer, thickener and tripropylene glycol in sequence A film-forming aid mixed with n-butyl ether and ethanol at a ratio of 10:1, then stirred and dispersed at a speed of 1400r / min for 30 minutes, and finally added with a pH regulator to adjust the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com