Method of increasing curing speed of phenolic resin adhesive

A technology of phenolic resin adhesive and curing speed, which is applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the limitations of the development and utilization of phenolic resin adhesives and market prospects, and it is difficult to maintain gluing Strength stability, strict requirements on veneer moisture content, etc., to achieve the effect of improving curing performance and thermal stability, film-forming and physical and mechanical properties, and reducing steric hindrance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

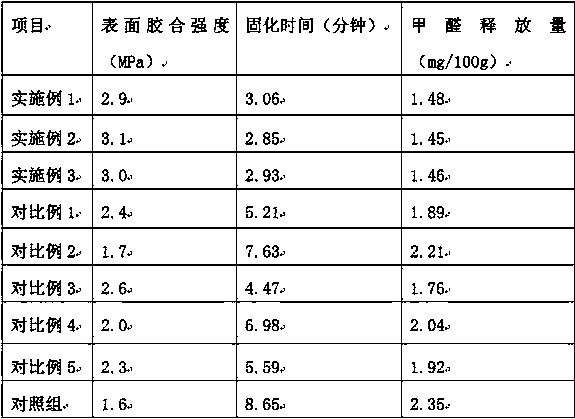

Examples

Embodiment 1

[0016] A method for improving the curing speed of a phenolic resin adhesive. During the preparation of the phenolic resin, the phenolic resin and formaldehyde are reacted according to a molar ratio of 1:1.9. In the first step, all the phenolic resin is added to a three-necked flask, Then add formaldehyde with a mass percentage of 17%, after mixing evenly, add the prepared modified catalyst, turn off the heater after heating up to 66°C for reaction, and after the reaction lasts for 30 minutes, control the reaction temperature in the range of 88-90°C, Continue to react for 40 minutes; in the second step, add the remaining formaldehyde into the reaction system, react at 85-88°C for 35 minutes, cool naturally to 34°C, and the gel can be released; the preparation method of the modified catalyst includes The following steps:

[0017] (1) Weigh 18.5 grams of zinc acetate dihydrate and 1.9 grams of nano-titanium dioxide, add them in turn to a beaker containing 150 ml of absolute ethan...

Embodiment 2

[0024] A method for increasing the curing speed of a phenolic resin adhesive. During the preparation of the phenolic resin, the phenolic resin and formaldehyde are reacted according to a molar ratio of 1:1.95. In the first step, all the phenolic resin is added to a three-necked flask. Then add formaldehyde with a mass percentage of 18.5%, after mixing evenly, add the prepared modified catalyst, turn off the heater to react after heating up to 67°C, and control the reaction temperature in the range of 88-90°C after the reaction is carried out for 32 minutes. Continue to react for 45 minutes; in the second step, add the remaining formaldehyde into the reaction system, react at 85-88°C for 38 minutes, cool naturally to 35°C, and the gel can be released; the preparation method of the modified catalyst includes The following steps:

[0025] (1) Weigh 18.6 grams of zinc acetate dihydrate and 1.95 grams of nano-titanium dioxide, add them in turn to a beaker containing 155 ml of absol...

Embodiment 3

[0032]A method for improving the curing speed of a phenolic resin adhesive. During the preparation of the phenolic resin, the phenolic resin and formaldehyde are reacted according to a molar ratio of 1:2.0. In the first step, all the phenolic resin is added to a three-necked flask. Then add formaldehyde with a mass percentage of 20%, after mixing evenly, add the prepared modified catalyst, turn off the heater after heating up to 68°C for reaction, and after the reaction lasts for 35 minutes, control the reaction temperature in the range of 88-90°C, Continue to react for 50 minutes; in the second step, add the remaining formaldehyde into the reaction system, react at 85-88°C for 40 minutes, cool naturally to 36°C, and the gel can be released; the preparation method of the modified catalyst includes The following steps:

[0033] (1) Weigh 18.7 grams of zinc acetate dihydrate and 2.0 grams of nano-titanium dioxide, add them in turn to a beaker containing 160 ml of absolute ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com