High-speed brake lining with elastic structure

An elastic structure, high-speed technology, used in railway car body parts, railway braking systems, brakes for special railway systems, etc. Partial wear and other problems, to achieve the effect of excellent anti-salt spray performance, short braking distance and stable braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

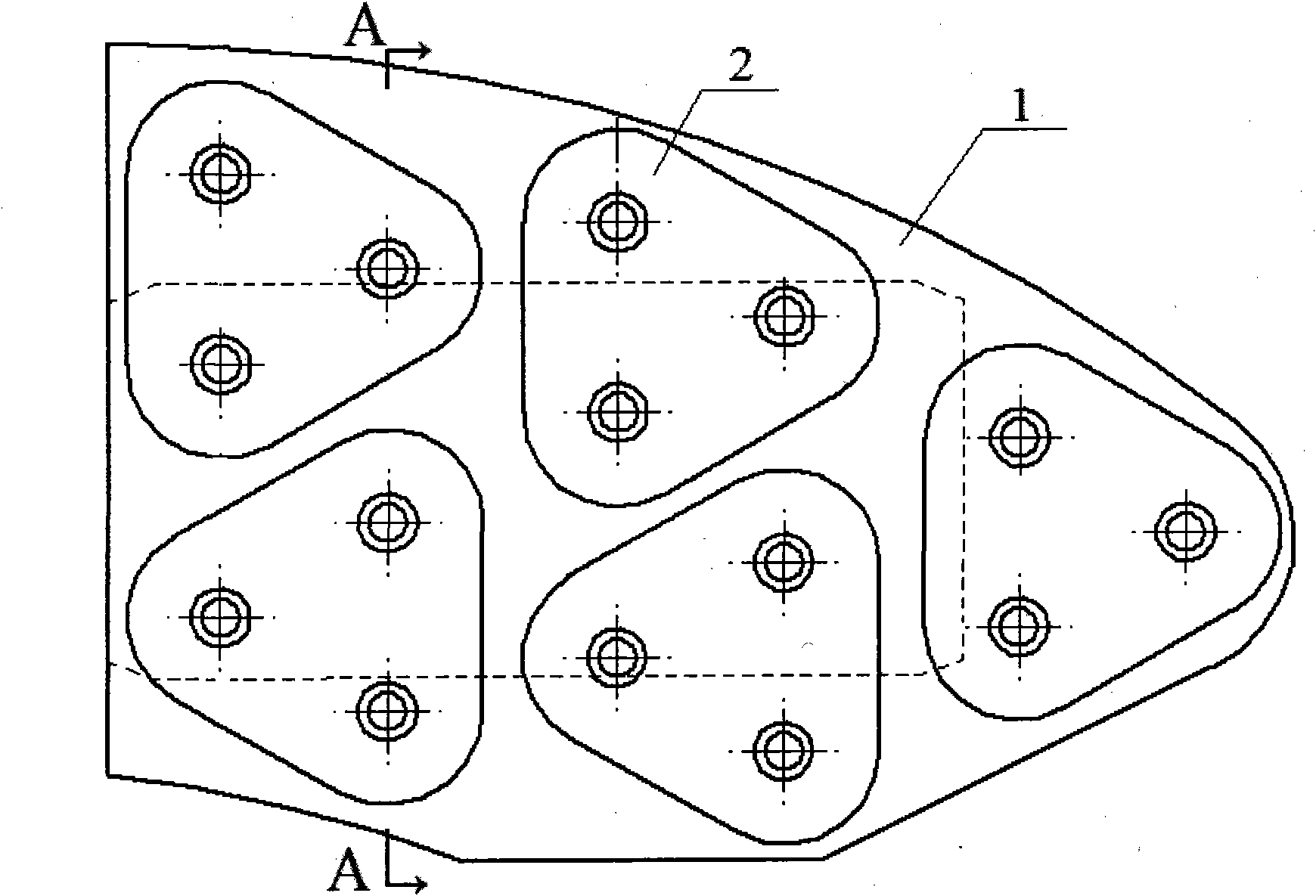

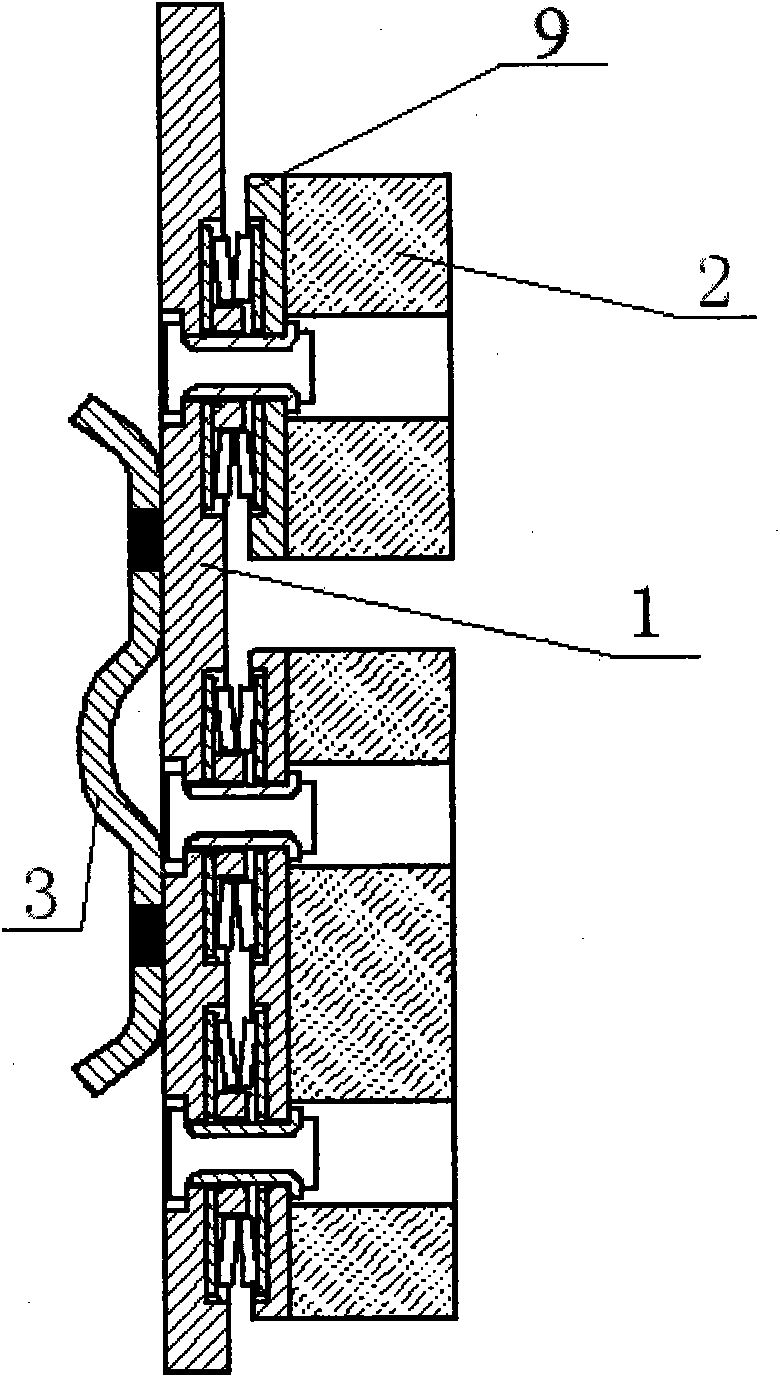

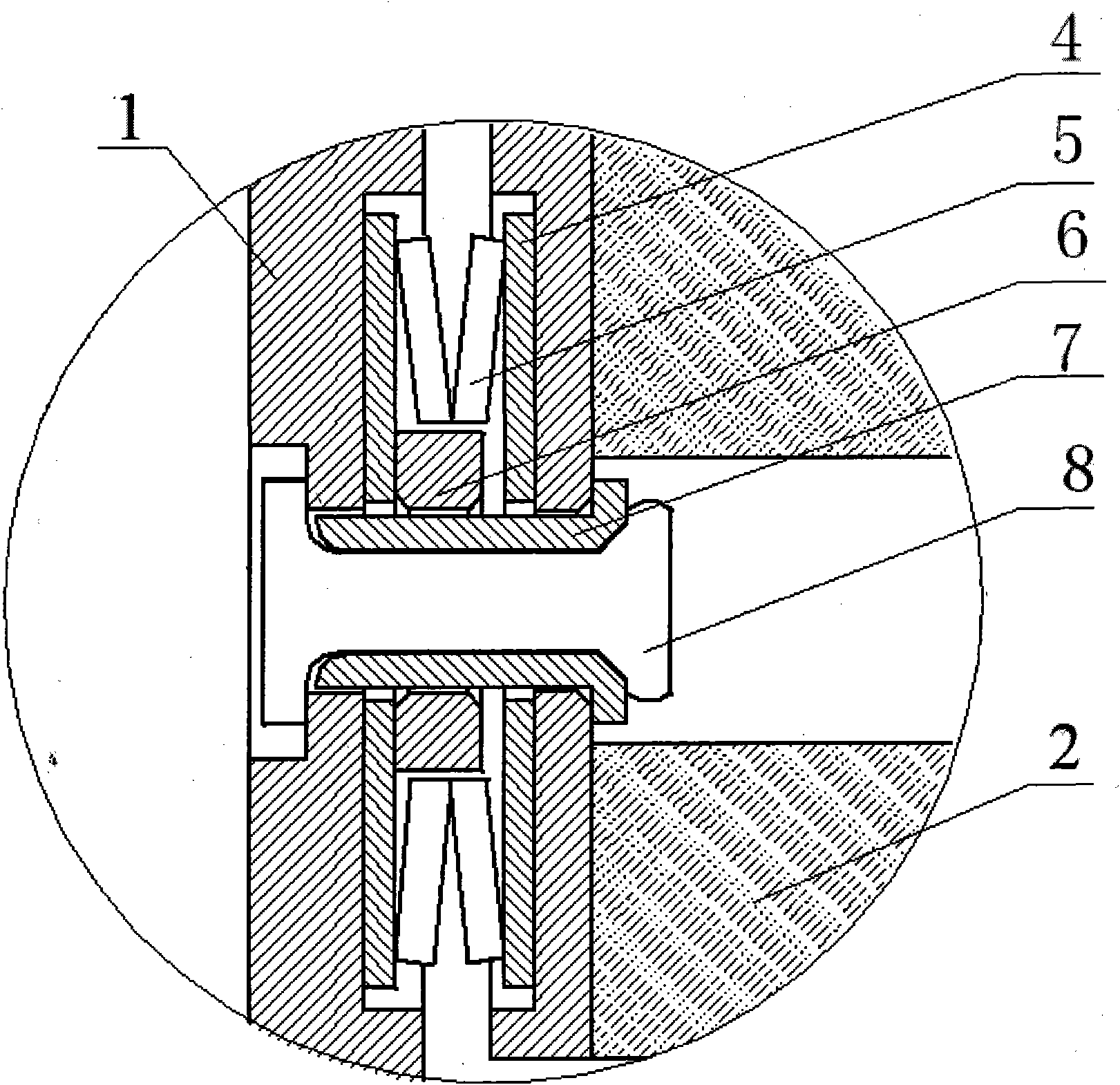

[0025] With reference to the accompanying drawings, the high-speed brake pad with elastic structure disclosed by the present invention is composed of a steel back 1, a brake block 2, a dovetail plate 3, a washer 4, a disc spring 5, a guide sleeve 6, a bush 7, and a rivet 8. After the processing of each part and the sintering of the brake block 2 are completed, the riveting work of each part is carried out first, specifically: the rivet 8 is passed through the rivet hole on the steel back 1, and then a gasket 4 is set on the rivet 8 , and then the guide sleeve 6 is installed between the rivet 8 and the two disc springs 5, and the two disc springs 5 are as image 3 The way shown is set back to back outside the guide sleeve 6, then insert another washer 4, then insert the brake block 2 into the rivet 8 through its rivet hole, and finally set the bushing 7 on the inside of the guide sleeve 6 on the outside of the rivet 8.

[0026] The function of the bushing 7 is to ensure that w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com