Copper material passivator, preparation and application thereof

A technology of passivating agent and copper material, which is applied in the field of surface passivation treatment, can solve the problems of prone to macula and poor corrosion resistance, and achieve the effects of excellent salt spray resistance, easy operation and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

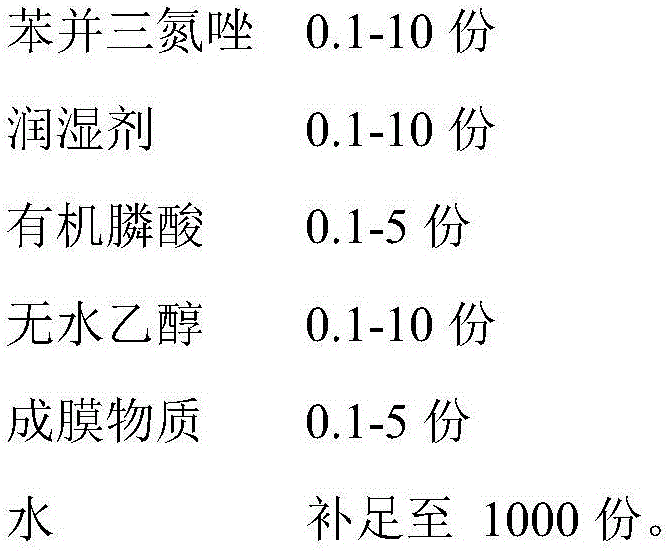

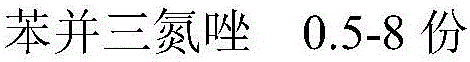

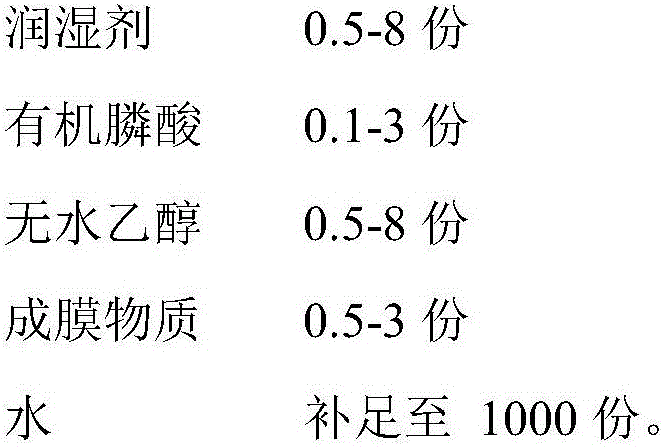

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of copper passivator: put 3 parts of benzotriazole and 2.5 parts of absolute ethanol in 400 parts of water, stir and mix to promote the dissolution of benzotriazole to obtain a colorless and transparent solution; then add 2 parts of OP-10, 1 part of dimethylglycine phosphonoglycine and 1.5 parts of polyacrylic acid resin are stirred and mixed, and finally 590 parts of water are added to obtain a uniformly mixed copper passivator.

[0029] The application method of copper passivation agent: at room temperature, put the cleaned brass and red copper into the passivation agent for surface passivation treatment, and the soaking time is 8 minutes. Then use the air flow to blow off the residual liquid on the surface of the copper until there is no visible residual liquid, put it into the drying tunnel for drying to promote film formation; the drying temperature is 150°C, and the drying time is 5 minutes.

Embodiment 2

[0031] The preparation method of copper passivator: put 0.1 part of benzotriazole and 10 parts of absolute ethanol in 300 parts of water, stir and mix to promote the dissolution of benzotriazole to obtain a colorless and transparent solution; then add 10 parts of Stir and mix OP-10, 0.1 part of hydroxyhexylidene diphosphonic acid and 0.1 part of polyurethane resin, and finally add 679.7 parts of water to obtain a uniformly mixed passivator for copper materials.

[0032] The application method of copper passivation agent: at room temperature, put the cleaned brass and red copper into the passivation agent for surface passivation treatment, soaking time is 2min. Then use the air flow to blow off the residual liquid on the surface of the copper until there is no visible residual liquid, put it into the drying tunnel for drying to promote film formation; the drying temperature is 80°C, and the drying time is 20 minutes.

Embodiment 3

[0034] The preparation method of copper passivator: put 8 parts of benzotriazole and 0.5 part of absolute ethanol in 500 parts of water, stir and mix to promote the dissolution of benzotriazole to obtain a colorless and transparent solution; then add 0.5 parts of OP-10, 3 parts of 2-phospho-1,2,4-tricarboxylic acid butane and 3 parts of polyvinyl alcohol resin are stirred and mixed, and finally 485 parts of water are added to obtain a uniformly mixed copper passivator.

[0035] The application method of copper passivation agent: at room temperature, put the cleaned brass and red copper into the passivation agent for surface passivation treatment, soaking time is 5min. Then use the air flow to blow off the residual liquid on the surface of the copper until there is no visible residual liquid, put it into the drying tunnel for drying to promote film formation; the drying temperature is 100°C, and the drying time is 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com