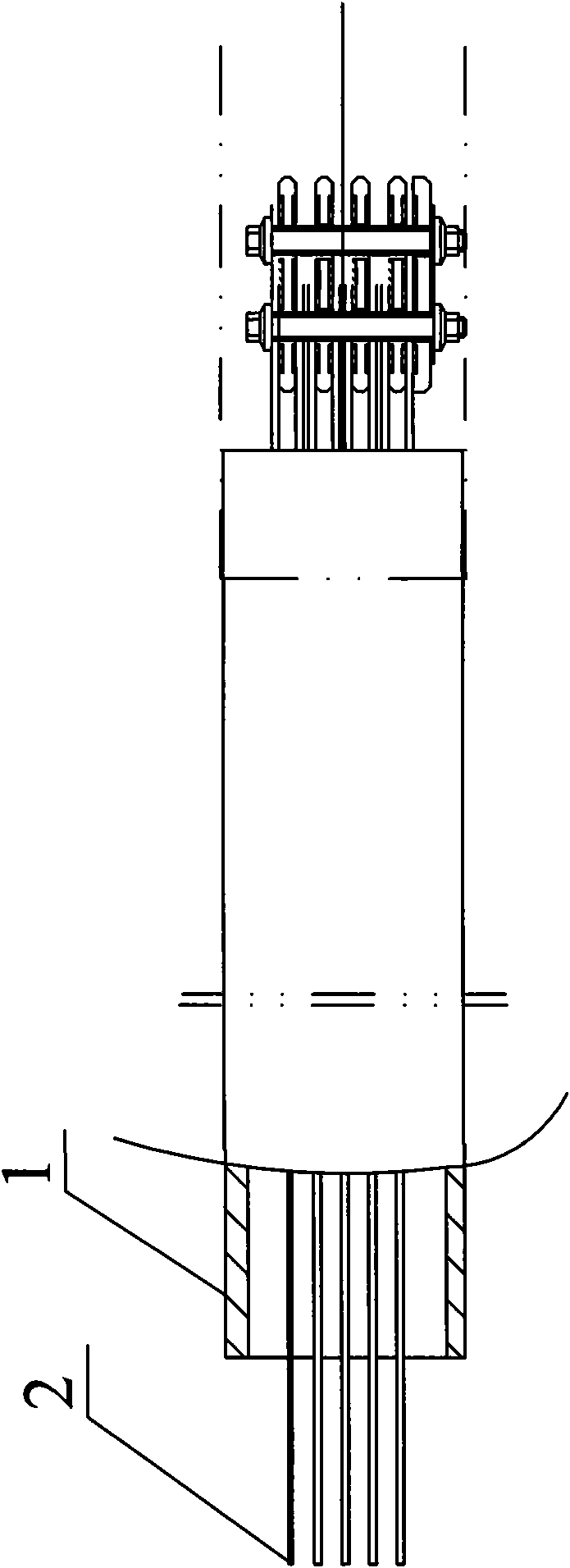

Solid bus slot with high strength

A busway, high-strength technology, applied in the field of busway, can solve the problems of easy rust of metal casing, short circuit of busway, low impact strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Firstly, polybutadiene diol was heated to 80°C for 6 hours under a vacuum of 0.05Mpa to dehydrate, and then toluene diisocyanate was put into the dehydrated polybutadiene diol reaction kettle, so that -NCO and -OH The molar ratio is 1.9: 1; then when heated to 75°C, heat preservation reaction for 3 hours, at this time, the viscosity becomes larger and the prepolymer has formed; add 1% γ-aminopropyltriethoxysilane in the reaction kettle, Stir well. Add dry 200-mesh mica powder and 200-mesh quartz sand powder in an amount of 4%, and stir evenly; add 8% dry flame retardant decabromodiphenyl ether, stir well, and vacuum degassing at the same time; add 0.1% UV absorber 2-(2'-hydroxy-3', 5'-di-tert-butylphenyl)-5-chlorobenzotriazole; add 0.5% antioxidant 1010 and 1% azo dye Stir well; then break the vacuum, add the calculated amount of 1,4-butanediol and stir evenly, then vacuum degassing. Finally, pour the above composite material into the mold with the copper bars install...

Embodiment 2

[0042] Firstly, polybutadiene diol was heated to 85°C for 5 hours under a vacuum of 0.08Mpa to dehydrate, and then toluene diisocyanate was put into the dehydrated polybutadiene diol reaction kettle, so that -NCO and -OH The molar ratio is 2.1:1; then heated to 78°C and kept warm for 3 hours, at this time, the viscosity becomes larger and the prepolymer has been formed; add 1.5% of γ-glycidyl etheroxypropyl trimethoxy to the reaction kettle Silane, stir well. Add dry 400-mesh mica powder and 300-mesh quartz sand powder in an amount of 10%; add 2% dioctyl phthalate and stir evenly; add 35% dry flame retardant microencapsulated red phosphorus, and stir Evenly, vacuum degassing at the same time; add 0.3% of ultraviolet absorber 2-hydroxy-4-methoxybenzophenone, then add 1% antioxidant 264 and 0.5% phthalocyanine blue and stir well; then break the vacuum, add The calculated amount of molten 3,3'-dichloro-4,4'-diamino-diphenylmethane was stirred evenly, and then vacuum degassed. F...

Embodiment 3

[0044] Firstly, polybutadiene diol was heated to 90°C for 7 hours under a vacuum of 0.1Mpa to dehydrate, and then toluene diisocyanate was put into the dehydrated polybutadiene diol reaction kettle, so that -NCO and -OH The molar ratio is 2.5:1; then heat it to 80°C and keep it warm for 4 hours. At this time, the viscosity becomes larger and the prepolymer has been formed; add 0.5% anilinomethyltriethoxysilane into the reaction kettle and stir evenly . Add dry 500-mesh mica powder and 600-mesh quartz sand powder in an amount of 20%, and stir evenly; add 20% dry flame retardant antimony trioxide, stir well, and vacuum debubble at the same time; add 0.4% ultraviolet light Absorbent 2,4-dihydroxybenzophenone; then add 2% antioxidant 1010 and 1.5% azo dye and stir; then break the vacuum, add the calculated amount of 1,6-butanediol and stir evenly, then Vacuum degassing. Finally, pour the above composite material into the mold with the copper bars installed, and then vacuumize to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com