Zirconium salt chemical conversion treatment method for surface of die-casting aluminum alloy

A chemical conversion treatment, casting aluminum alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of hexavalent chromium environment and human harm, high cost of organosilane treatment, slow speed, etc., to achieve improved salt spray resistance, resistance to The effect of improving the corrosion performance

Inactive Publication Date: 2012-07-04

UNIV OF SCI & TECH BEIJING

View PDF11 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the problems existing in the prior art, such as the harm of hexavalent chromium to the environment and the human body, the high cost of organosilane treatment and the slow speed, and there is currently no Aiming at problems such as the development of chemical conversion treatment process for die-casting aluminum alloy, it provides an environment-friendly, low-cost, high-speed and good anti-corrosion effect of die-casting aluminum alloy surface environmental protection zirconium salt chemical conversion treatment solution and process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

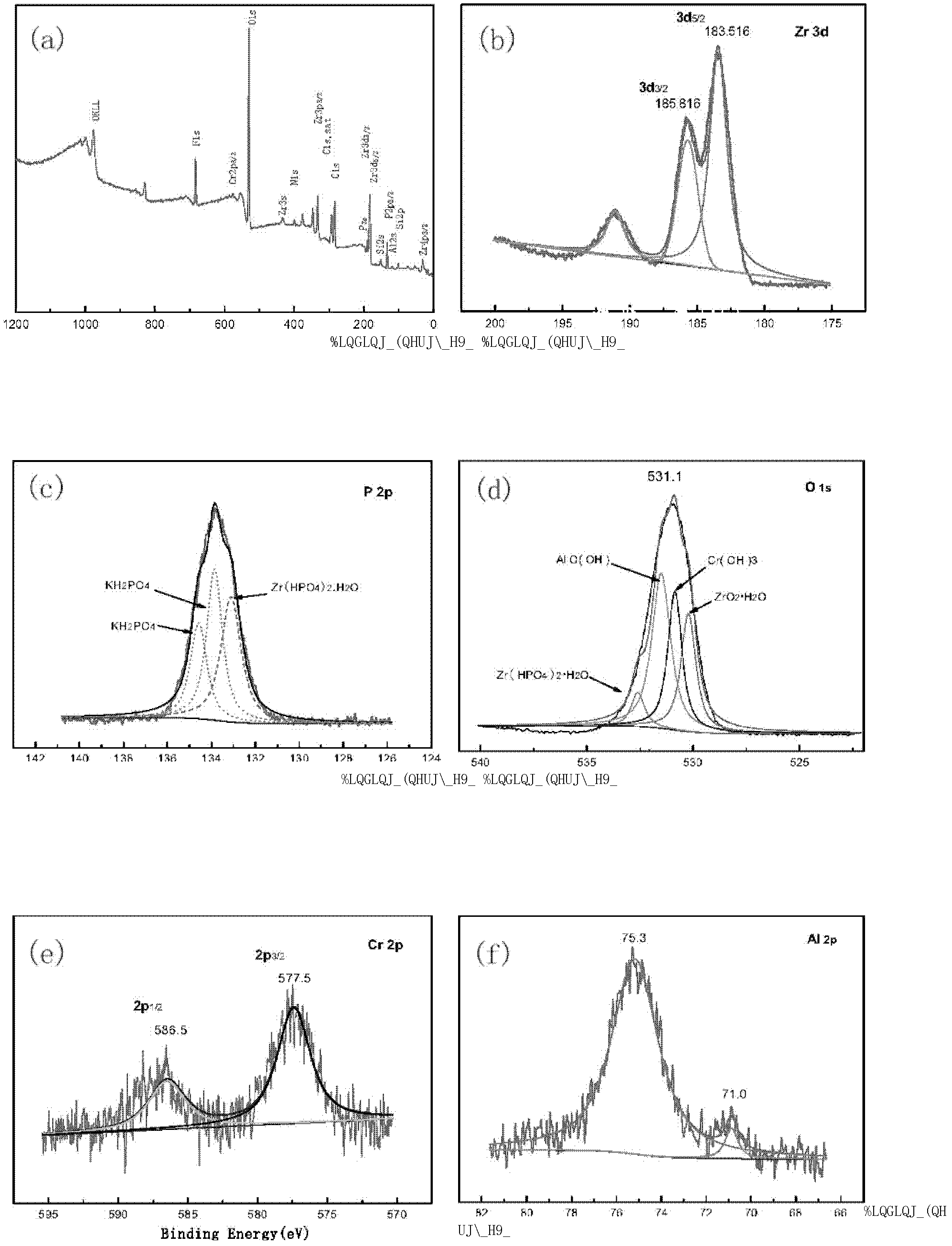

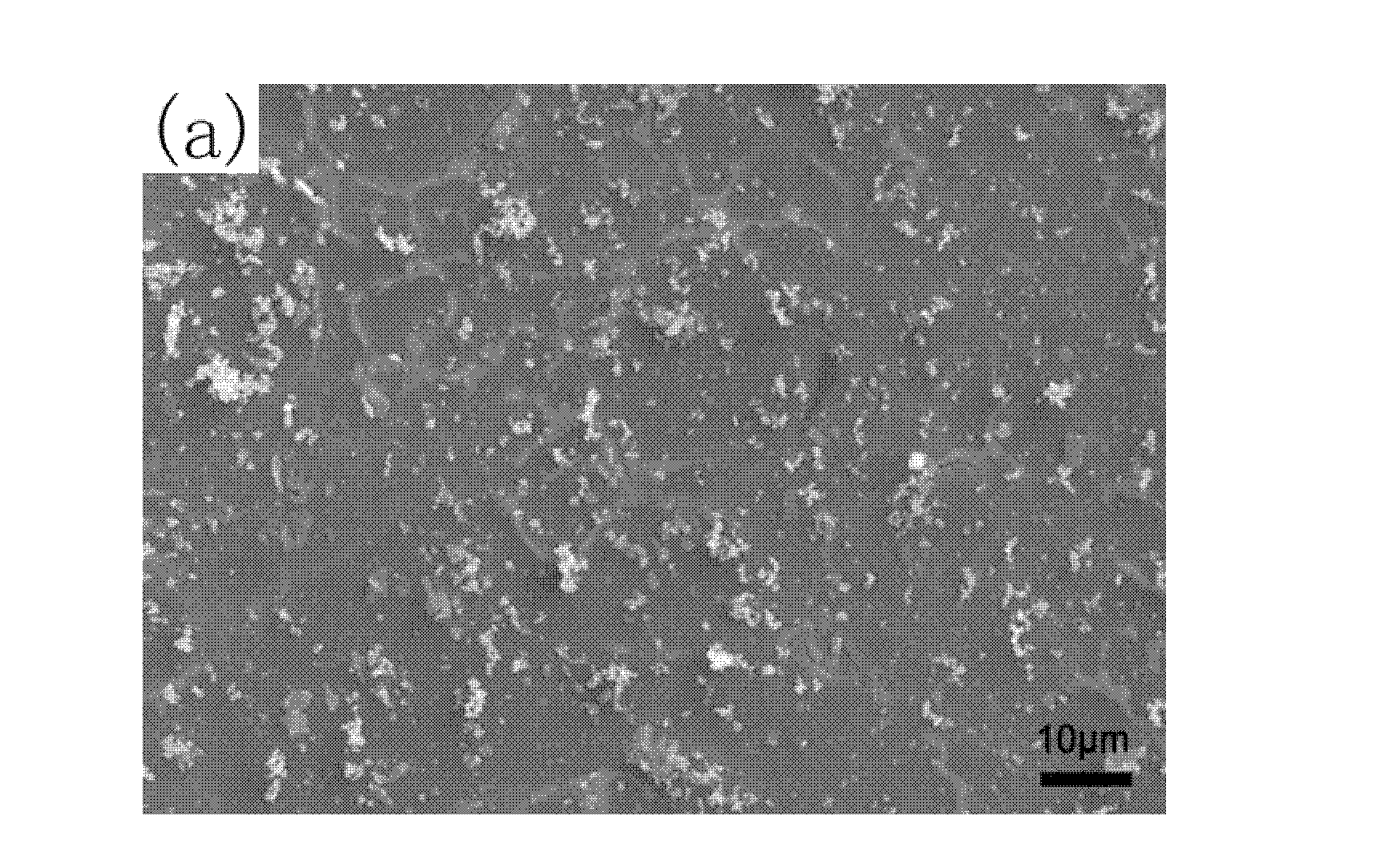

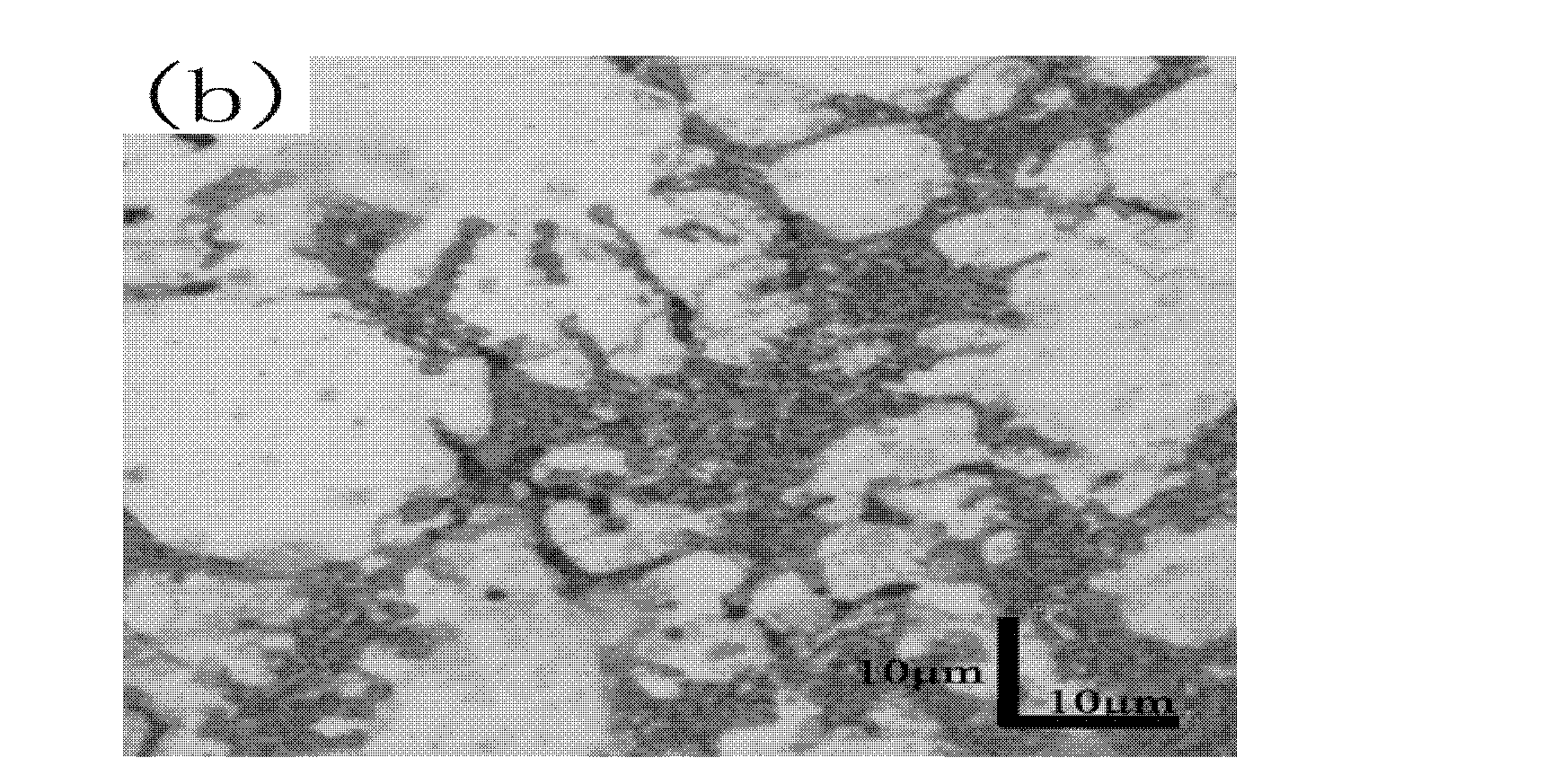

The invention belongs to the field of metallic materials and relates to a chemical conversion solution and a treatment method for the surface of a die-casting aluminum alloy. The conversion solution is formed by compounding an A ingredient and a B ingredient, the A ingredient consists of a zirconium salt, a surfactant and a trivalent chromium salt; the B ingredient consists of a complexing agent and a film-forming accelerant; in the A ingredient, the content of the zirconium salt is 5-60 g / L, the content of the surfactant is 2-10 g / L, and the content of the trivalent chromium salt is 5-50 g / L; in the B ingredient, the content of the complexing agent is 4-20 g / L, and the content of the film-forming accelerant is 2-15 g / L; and the method comprises the pretreatment on the surface of the die-casting aluminum alloy and the zirconium salt chemical conversion treatment. A chemical conversion coating contains zirconium phosphate compounds and a small amount of trivalent chromium compounds, wherein the coating has uniform light blue and the thickness of about 0.5-1 micron. The zirconium salt chemical conversion coating prepared by the method has excellent corrosion resistance, the bonding strength between the coating and a substrate is high, the product, the waste water and the waste liquor obtained after the chemical conversion treatment do not contain hexavalent chrome which is harmful to the environment and the health of human bodies.

Description

technical field [0001] The invention belongs to the field of metal materials, and relates to a chemical conversion solution and a treatment method for the surface of a die-casting aluminum alloy, in particular to an environmentally friendly zirconium salt chemical conversion treatment on the surface of a die-casting aluminum alloy containing high silicon and copper elements. A uniform and dense protective film layer is obtained on the surface of the parts, and this film is used as a bare film of die-casting aluminum alloy parts to improve its corrosion resistance. Background technique [0002] Die-casting is a rapid production process. The mass production of parts is fast, low-cost, high-precision and can be used to manufacture parts with complex shapes. 95% of die-casting aluminum alloys are recyclable after machining, aluminum die-casting is a very green and sustainable alternative. The domestic die-casting industry has achieved rapid development since the 1990s, and the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C22/07C23C22/38

Inventor 庞晓露朱政高克玮王化平陶保健

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com