Machining method of electric appliance cabinet

A processing method and technology of electrical cabinets, which are applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, casings/cabinets/drawer parts, etc., can solve problems such as coating aging, and achieve long anti-corrosion time and production efficiency. The effect of simple process and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

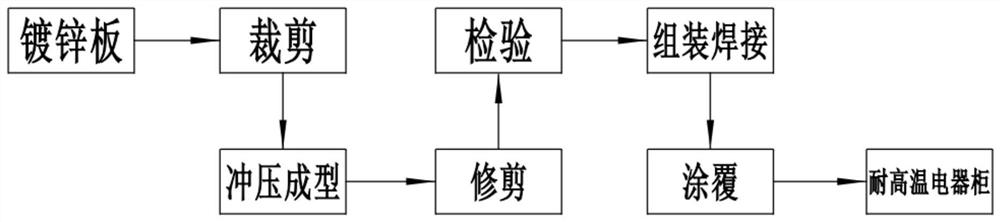

Image

Examples

preparation example Construction

[0042] Further, the preparation method of high temperature resistant coating comprises the following steps:

[0043] A: First put petroleum resin and solvent into the stirring tank for mixing, control the temperature in the stirring tank at 52°C, set the stirring speed at 120r / min, and stir for 20min, then put in the modified acrylic resin and continue stirring. Stirring time is 10min;

[0044] B: Add resin plasticizer, set stirring speed to 600r / min, stirring time 60min, stir until colorless transparent viscous liquid, then add epoxy resin and continue stirring for 20min;

[0045] C: Then add the configured multi-functional auxiliary agent into the stirring tank and stir evenly, the stirring speed is 550r / min, the stirring time is 60min, and the temperature in the stirring tank is controlled at 35°C;

[0046] D: Finally, add surfactant and complex rare earth and stir for 30 minutes at a stirring speed of 200r / min to obtain a high temperature resistant coating.

[0047] Furt...

Embodiment 1

[0051] A processing method for an electrical cabinet, comprising the following steps:

[0052] (1) Use galvanized sheet as the material for making the cabinet;

[0053] (2) According to the shape of the electrical cabinet, the electrical cabinet is divided into four parts: the door, the rear shell, the base and the top cover;

[0054] (3) Cut the selected galvanized sheet according to the preset size, punch and bend the cut sheet on the punching machine;

[0055] (4) Trim flashes and burrs on the stamped and bent galvanized sheet, and after passing the inspection, it becomes the semi-finished product of the electrical cabinet;

[0056] (5) Combine and install the semi-finished electrical cabinets that have passed the inspection, assemble them into a complete electrical cabinet, and then weld them into shape;

[0057] (6) Apply high temperature resistant paint on the surface of the cabinet to form a paint layer to obtain a high temperature resistant cabinet.

[0058] Further...

Embodiment 2

[0070] A processing method for an electrical cabinet, comprising the following steps:

[0071] (1) Use galvanized sheet as the material for making the cabinet;

[0072] (2) According to the shape of the electrical cabinet, the electrical cabinet is divided into four parts: the door, the rear shell, the base and the top cover;

[0073] (3) Cut the selected galvanized sheet according to the preset size, punch and bend the cut sheet on the punching machine;

[0074] (4) Trim flashes and burrs on the stamped and bent galvanized sheet, and after passing the inspection, it becomes the semi-finished product of the electrical cabinet;

[0075] (5) Combine and install the semi-finished electrical cabinets that have passed the inspection, assemble them into a complete electrical cabinet, and then weld them into shape;

[0076] (6) Apply high temperature resistant paint on the surface of the cabinet to form a paint layer to obtain a high temperature resistant cabinet.

[0077] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com