Composite calcium naphthenate-based lubricating grease and preparation method therefor

A calcium naphthenate-based, calcium naphthenate technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as high price of calcium sulfonate with high alkalinity, lack of rapid promotion, complicated preparation process, etc., and achieve excellent Good adhesion, long lubrication life, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

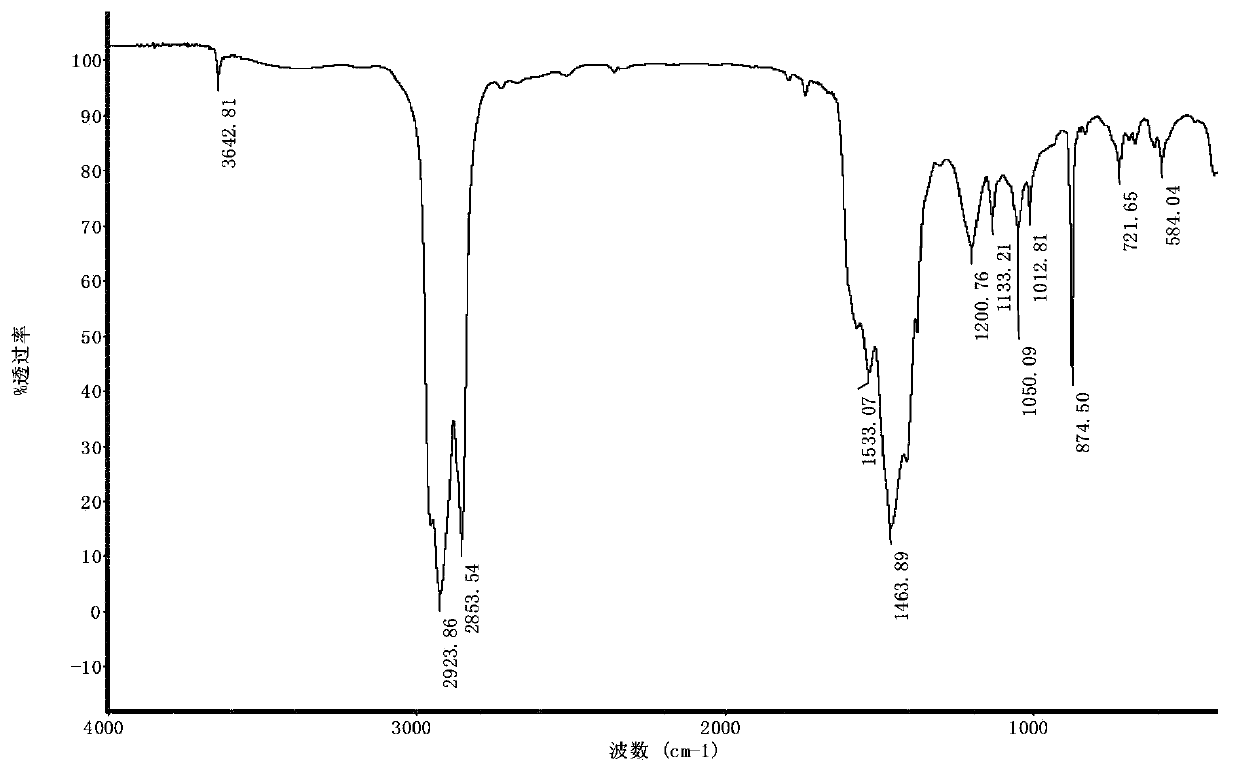

Image

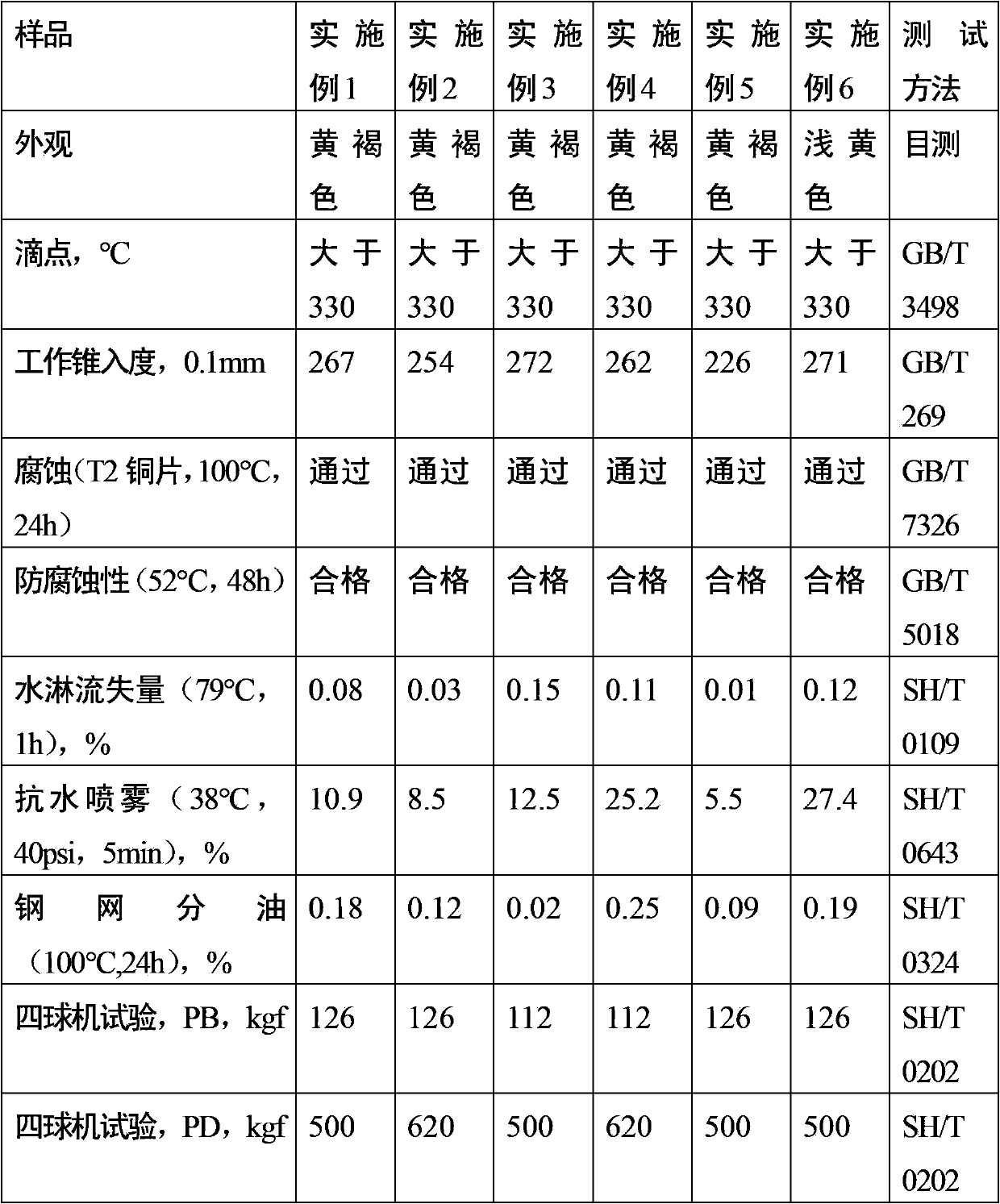

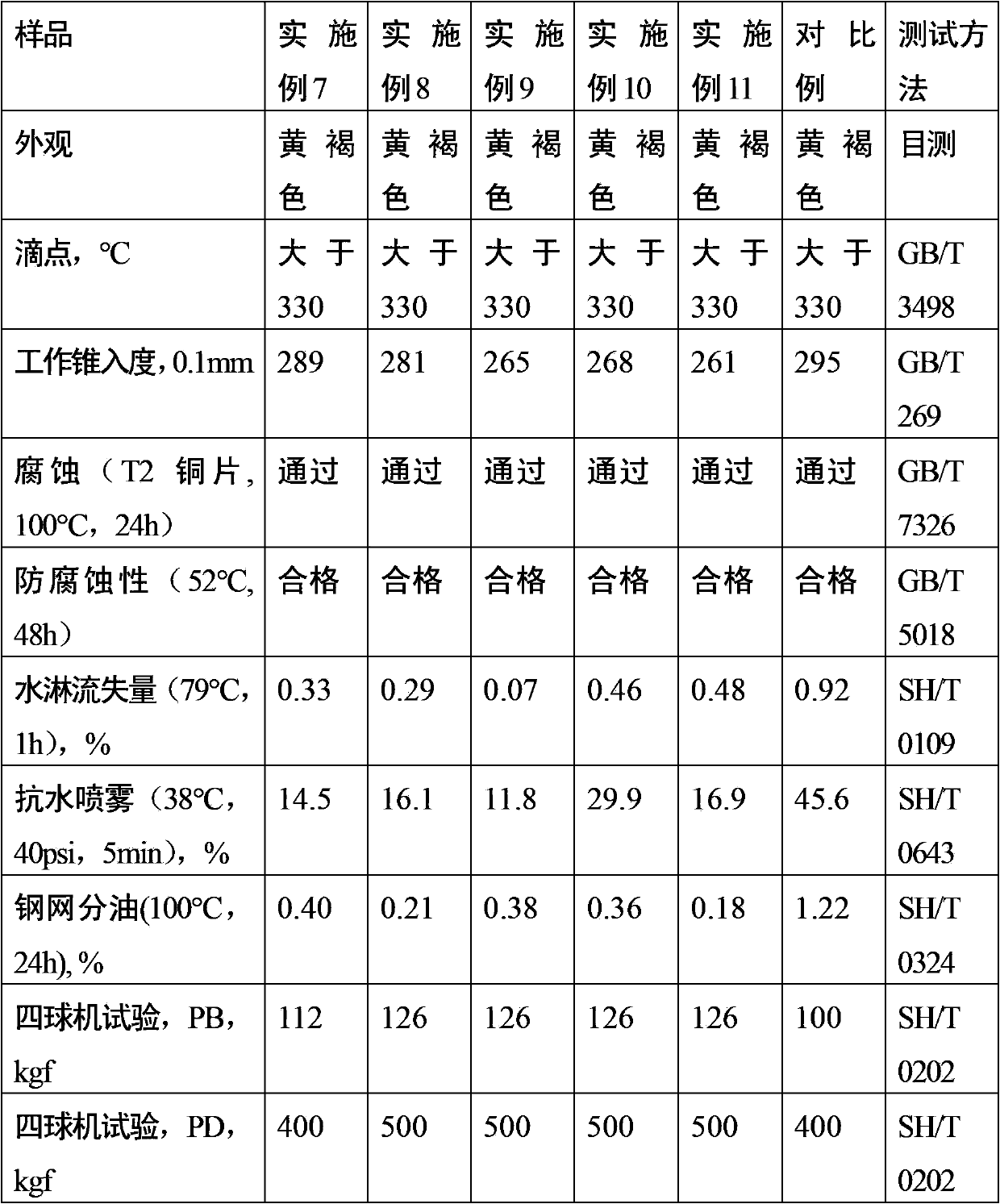

Examples

Embodiment 1

[0036] Raw material components: ultra-high base number calcium naphthenate (total base number 400mgKOH / g, 30kg); 150BS (30kg); C16-C50 naphthenic acid (2.8kg); acetic acid (0.56kg); Ca(OH) 2 (1.8kg); 12-Hydroxystearic Acid (2kg); Boric Acid (2.32kg); 500SN (18kg).

[0037] In a volume of 110L and with heating, stirring, circulation, cooling of the normal pressure reactor, add 30kg total alkali value of 400mgKOH / g calcium naphthenate and 30kg 100 ° C kinematic viscosity is 31mm 2 / s HVI150BS lubricating base oil, stir, heat up to 50°C, keep the temperature for 10 minutes; add 2.8kg naphthenic acid, control the temperature at about 50°C, stir for 10 minutes; add 0.56kg of acetic acid and 4 times the weight of acetic acid The aqueous solution of stirring 10 minutes; Be warming up to 60 ℃, constant temperature 90 minutes, material thickens; Add 1.8kgCa(OH) 2 And dilute the suspension with 4 times of water, stir for 10 minutes; add 2kg of 12-hydroxystearic acid, stir for 10 minutes...

Embodiment 2

[0040] Raw material components: super high base number calcium naphthenate (total base number 420mgKOH / g, 30kg); 150BS (30kg); C16-C50 naphthenic acid (2.8kg); acetic acid (0.56kg); Ca(OH) 2 (1.8kg); 12-Hydroxystearic Acid (2kg); Boric Acid (2.32kg); 500SN (18kg).

[0041] Prepare ultra-high base value calcium naphthenate-based grease by the method of example 1, the difference is that the total base value of the ultra-high base value calcium naphthenate used is 420mgKOH / g, and the performance data of the obtained grease finished product are shown in Table 1.

[0042] In the lubricating grease obtained in this embodiment, based on the weight of the lubricating grease, the composition is: 38.5% of non-Newtonian calcium naphthenate; 55.4% of lubricating base oil; 2.4% of calcium 12-hydroxystearate; and 3.7% of calcium borate.

Embodiment 3

[0044] Raw material components: super high base number calcium naphthenate (total base number 400mgKOH / g, 30kg); 150BS (20kg); butanol (2.8kg); acetic acid (0.56kg); Ca(OH) 2 (1.8kg); 12-Hydroxystearic Acid (2kg); Boric Acid (2.32kg); 500SN (28kg).

[0045] Super high base value composite calcium naphthenate-based lubricating grease was prepared according to the method of Example 1, except that butanol was used instead of naphthenic acid, and the amount of base oil was also changed. The performance data of the finished lubricating grease obtained are shown in Table 1.

[0046] In the lubricating grease obtained in this embodiment, based on the weight of the lubricating grease, the composition is: 38.5% of non-Newtonian calcium naphthenate; 55.4% of lubricating base oil; 2.4% of calcium 12-hydroxystearate; and 3.7% of calcium borate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com