Traveling floating cable for offshore platforms

A technology for floating cables and offshore platforms, applied in floating cables, power cables, insulated cables, etc., can solve the problems that ordinary power cables and control cables cannot meet the requirements of use, and achieve increased volume and structural stability, shielding interference signals, The effect of enhancing the overall tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

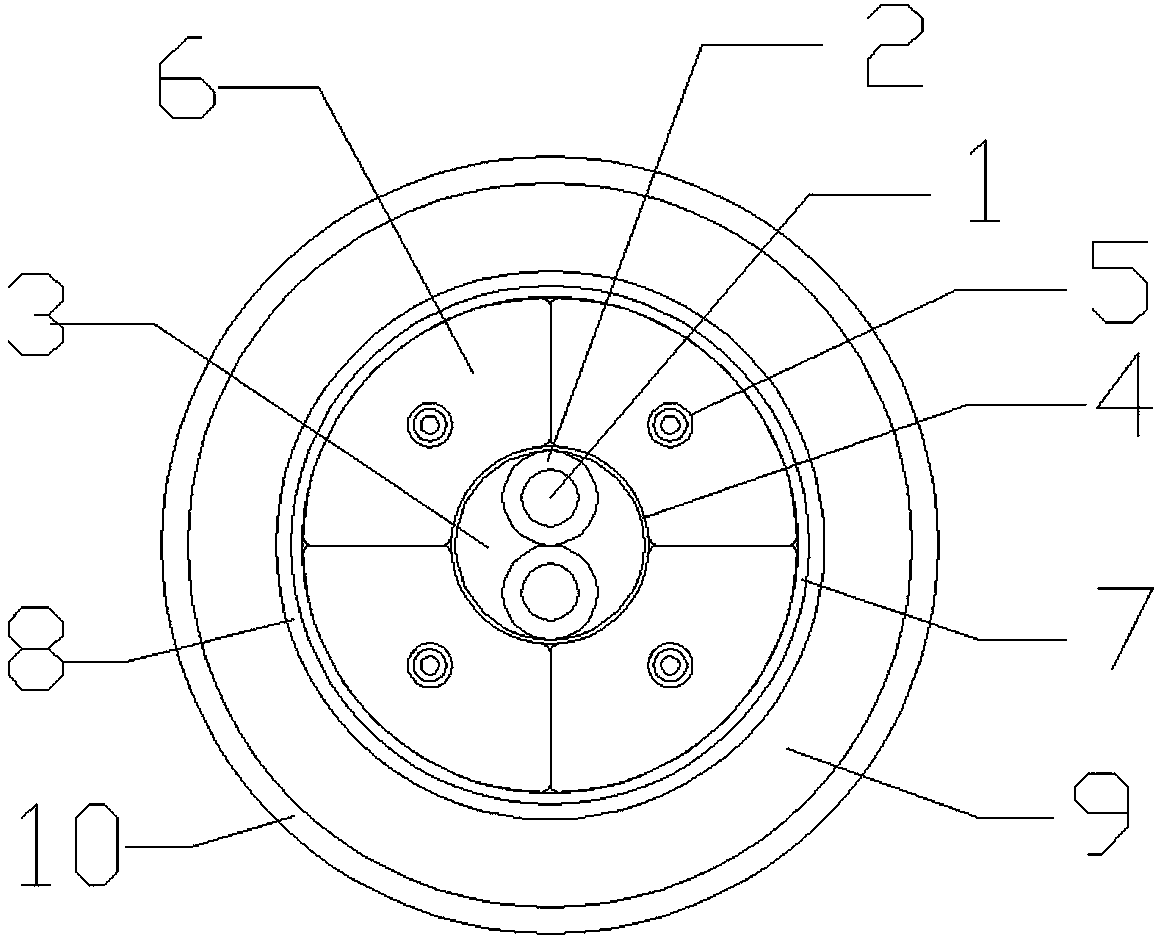

[0023] Such as figure 1 The accompanying floating cable for offshore platforms as shown includes a tinned copper conductor 1, a cross-linked polyethylene insulating layer 2 coated on the tinned copper conductor 1, and a carbon fiber braid coated on the cross-linked polyethylene insulating layer 2. The shielding layer 4, and the high-strength tensile filling layer 3 is filled between the cross-linked polyethylene insulating material 2 and the carbon fiber braided shielding layer 4. Ethylene filling layer 6, the foamed polyethylene filling layer 6 is covered with a Kevlar fiber braided reinforcing layer 7, and the Kevlar fiber braided reinforcing layer 7 is extruded with a medium density polyethylene inner sheath 8, the Medium-density polyethylene inner sheath 8 is extruded with foamed polyethylene sheath 9, said foamed polyethylene sheath 9 is extruded with medium-density polyethylene outer sheath 10, and the high-strength tensile filling layer is polyvinyl chloride .

Embodiment 2

[0025] Referring to Example 1, the number of the tinned copper conductors is 2.

Embodiment 3

[0027] Referring to Example 1, the foamed polyethylene filling layer is sector-shaped, and the arc of each sector is 90°.

[0028] Example 3:

[0029] Referring to Example 1, the control wire core includes copper wires twisted into a copper conductor and two layers of ceramic silicon rubber tapes wrapped around the copper conductor wire core.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com