Cartilage tissue engineering scaffold material and preparation method thereof

A scaffold material and cartilage tissue technology, applied in the field of cartilage tissue engineering scaffolds and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

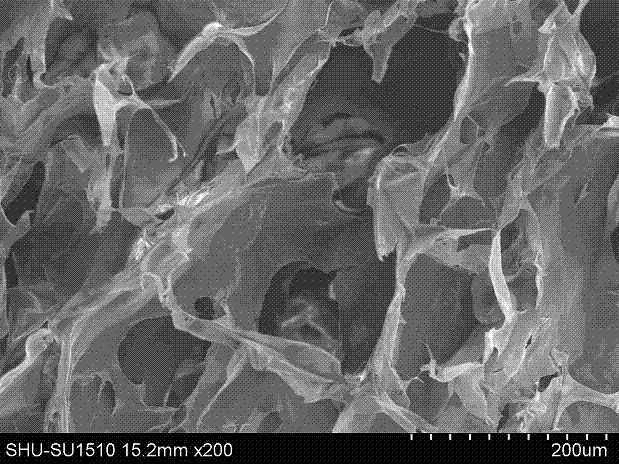

[0025] Prepare a 2.0% sodium alginate solution with deionized water, prepare a 2.0% chitosan solution with acetic acid solution, add 0.0641 g of 1-ethyl-(3-dimethyl Aminopropyl) carbodiimide hydrochloride (EDC??HCl) and 0.0077g of N-hydroxysuccinimide (NHS), stirring for 10 to 40 minutes; add the activated sodium alginate solution to 1mL shell In the polysaccharide solution, continue to stir slowly; after the viscosity changes slightly, pour it into a mold, freeze at -20°C for 12 to 24 hours, and then freeze-dry to obtain a sodium alginate / chitosan three-dimensional porous scaffold. The performance of the bracket is as follows after testing: the porosity is 94%; the pore diameter is 160-220?m.

Embodiment 2

[0027] Prepare the mass fraction of 2.0% sodium alginate solution with deionized water, prepare the mass fraction of 2.0% chitosan solution with acetic acid solution, add 0.1069g of 1-ethyl-(3-dimethyl Aminopropyl) carbodiimide hydrochloride (EDC??HCl) and 0.0128g of N-hydroxysuccinimide (NHS), stirring for 10 to 40 minutes; add the activated sodium alginate solution to 1mL shell In the polysaccharide solution, continue to stir slowly; after the viscosity changes slightly, pour it into a mold, freeze at -20°C for 12 to 24 hours, and then freeze-dry to obtain a sodium alginate / chitosan three-dimensional porous scaffold. The performance of the stent is as follows after testing: the porosity is 94%; the pore diameter is 170-220??m.

Embodiment 3

[0029] Prepare a 2.0% sodium alginate solution with deionized water, prepare a 2.0% chitosan solution with acetic acid solution, add 0.0641 g of 1-ethyl-(3-dimethyl Aminopropyl) carbodiimide hydrochloride (EDC??HCl) and 0.0077g of N-hydroxysuccinimide (NHS), stirring for 10 to 40 minutes; add the activated sodium alginate solution to 1mL shell In the polysaccharide solution, continue to stir slowly; after the viscosity changes slightly, pour it into a mold, freeze at -80°C for 12 to 24 hours, and then freeze-dry to obtain a sodium alginate / chitosan three-dimensional porous scaffold. The performance of the stent is as follows after testing: the porosity is 93%; the pore diameter is 80-120?m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com