Composite enhanced through coupling of flaky and linear thermal conductive materials and preparation method

A technology for strengthening composite materials and thermally conductive materials, applied in the field of composite materials, can solve problems such as difficulty in exerting thermal conductivity, and achieve the effect of improving bonding strength and preventing dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

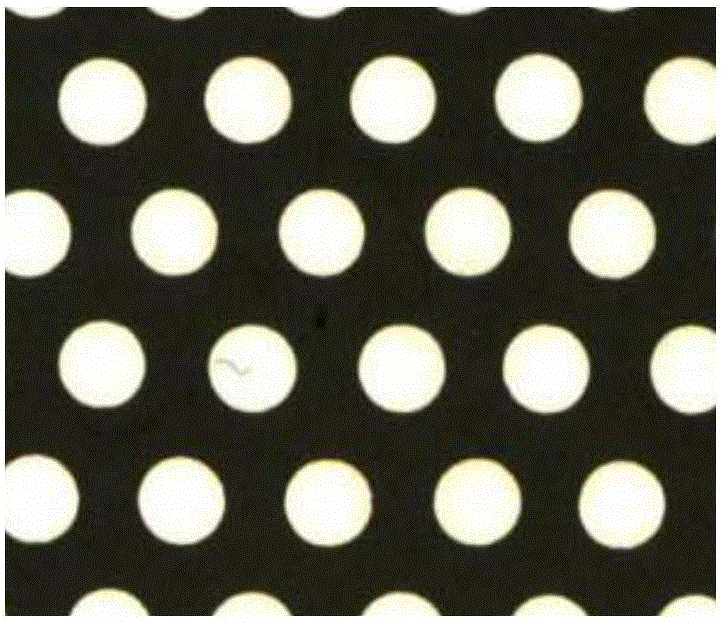

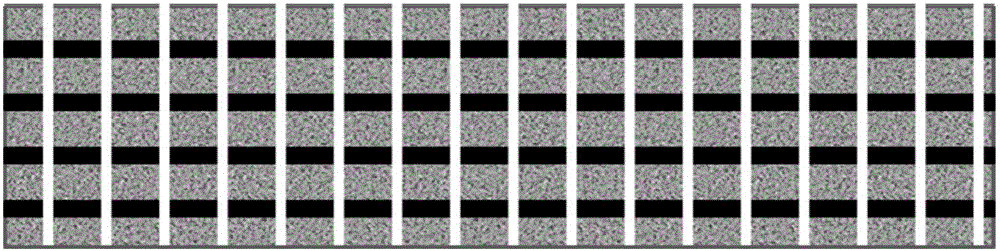

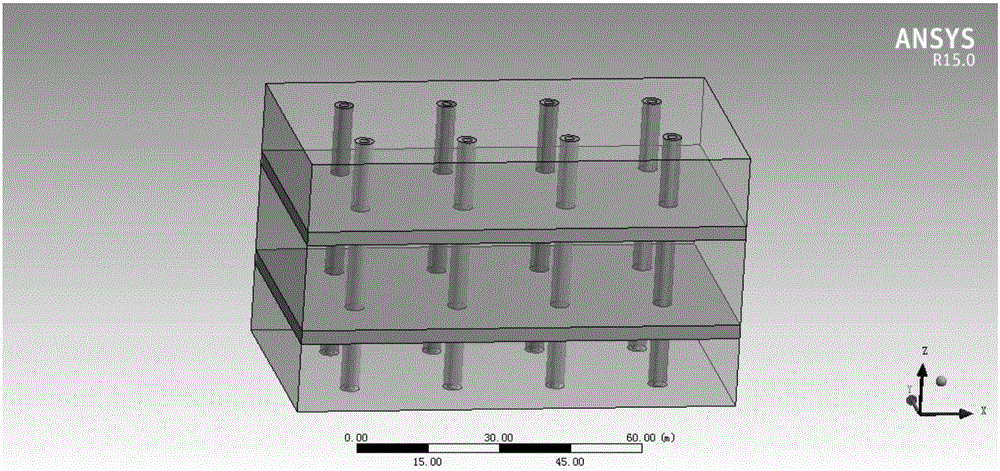

[0059] Cu foil is selected as the substrate material with a thickness of 0.3mm, and a high thermal conductivity diamond film is grown on its surface, that is, as a sheet-shaped thermal conductivity material. A series of parallel through-holes with a diameter of 3mm are arranged on the diamond sheet with a substrate. The spacing is 5mm; tungsten wire with a diameter of 0.3mm is used as the substrate to deposit diamond film as a linear heat-conducting material, and the composite is carried out according to the following steps:

[0060] (1) Pre-treatment of the surface of copper foil and tungsten wire: ultrasonic treatment with acetone to remove surface oil and stains, and ultrasonic acetone solution planting seed crystal treatment on copper foil tungsten wire substrate;

[0061] (2) Using magnetron sputtering to sputter a layer of W film on the surface of Cu foil in advance, the thickness of W film is 200nm; the surface of W-coated copper foil surface hot wire CVD to prepare diam...

Embodiment 2

[0066]W foil is selected as the substrate material with a thickness of 0.4mm, and a high thermal conductivity diamond film is grown on its surface, that is, as a sheet-shaped thermal conductivity material. A series of parallel through holes with a diameter of 3mm are arranged on the diamond sheet with the substrate. The spacing is 6mm; tungsten wire with a diameter of 0.5mm is selected as the substrate to deposit diamond film as a linear heat-conducting material, and the composite is carried out according to the following steps:

[0067] (1) Pre-treatment of the surface of tungsten foil and tungsten wire: that is, ultrasonic treatment with acetone to remove surface oil and stains, and ultrasonic acetone solution planting seed crystal treatment on tungsten foil and tungsten wire substrate;

[0068] (2) Using hot wire CVD to prepare diamond film on the surface of tungsten foil and tungsten wire Process parameters: hot wire distance 6mm, substrate temperature 850°C, hot wire tempe...

Embodiment 3

[0072] (5) A graphite sheet with a thickness of 2mm and a planar thermal conductivity of 1200W / (m K) is selected as the sheet-shaped heat-conducting material. A series of parallel through-holes with a diameter of 2mm are arranged on the graphite sheet, and the distance between the through-holes is 5mm. Choose a tungsten wire with a diameter of 1mm as the substrate to deposit a diamond film as a linear heat-conducting material, and perform the compounding according to the following steps:

[0073] (1) Carry out preliminary treatment on the surface of graphite sheet and W wire, that is, use acetone ultrasonic treatment to remove surface oil and stains, and plant seed crystals on W substrate ultrasonic acetone solution;

[0074] (2) Hot wire chemical vapor deposition is used to deposit diamond on the surface of tungsten wire. The deposition process parameters are: the mass flow rate of methane and hydrogen is 1.0%; the growth temperature is 800°C, the growth pressure is 3000Pa, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com