High temperature and high damping high entropy alloy and preparation method thereof

A high-entropy alloy and high-damping technology, which is applied in the field of high-temperature high-damping high-entropy alloys and their preparation, can solve the problem of not improving the high-temperature damping performance and mechanical properties, the mechanical properties of high-damping alloys need to be improved, and the relaxation strength of high-dimensional defects. and other problems, to achieve the effect of large composition application range, excellent mechanical properties and high temperature damping properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

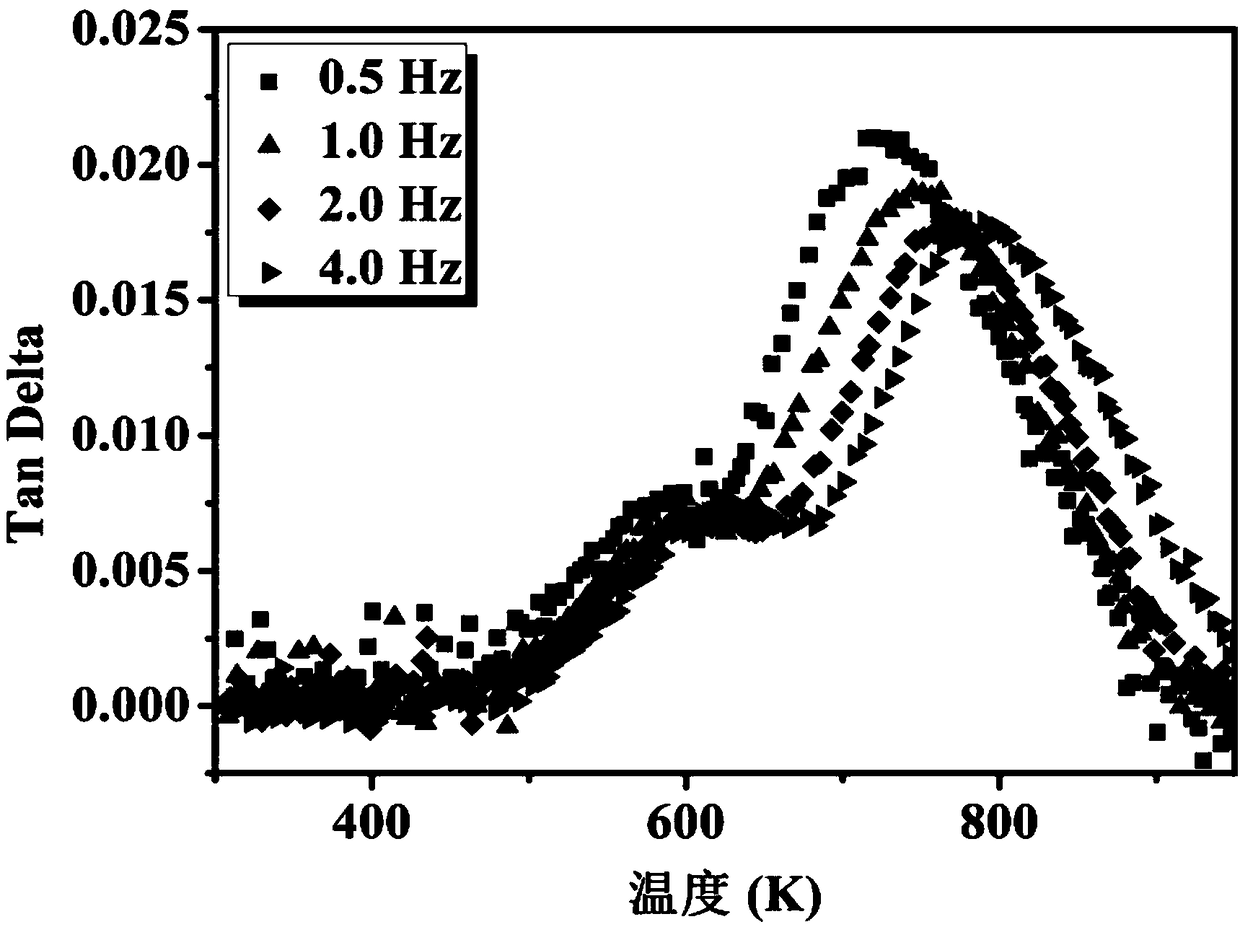

[0042] A kind of high temperature high damping high entropy alloy, its composition (atomic ratio) is: Ta 12.25 Nb 12.25 f 24.5 Zr 24.5 Ti 24.5 o 2 ,Such as figure 1 As shown, the alloy is a high damping alloy (tanδ max ≥0.01), and its damping relaxation peak temperature is greater than 700K, indicating that the alloy can be used in the field of high temperature shock absorption.

Embodiment 2

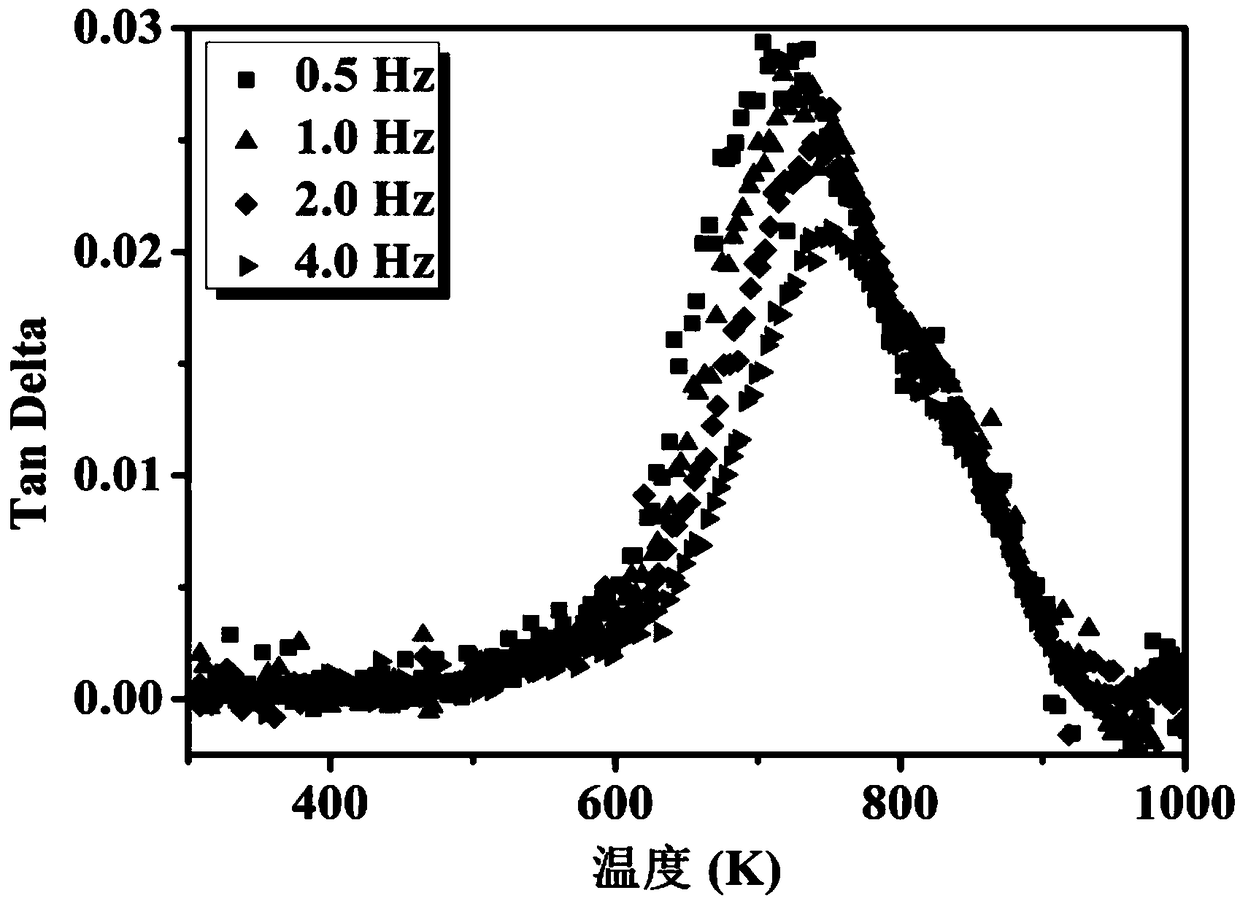

[0044] A kind of high temperature high damping high entropy alloy, its composition (atomic ratio) is: Ta 12.25 Nb 12.25 f 24.5 Zr 24.5 Ti 24.5 N 2 ,Such as figure 2 As shown, its tanδ max ≥0.01, it is a high-damping alloy, and its damping relaxation peak temperature is greater than 700K, indicating that the alloy can be used in the field of high-temperature shock absorption.

Embodiment 3

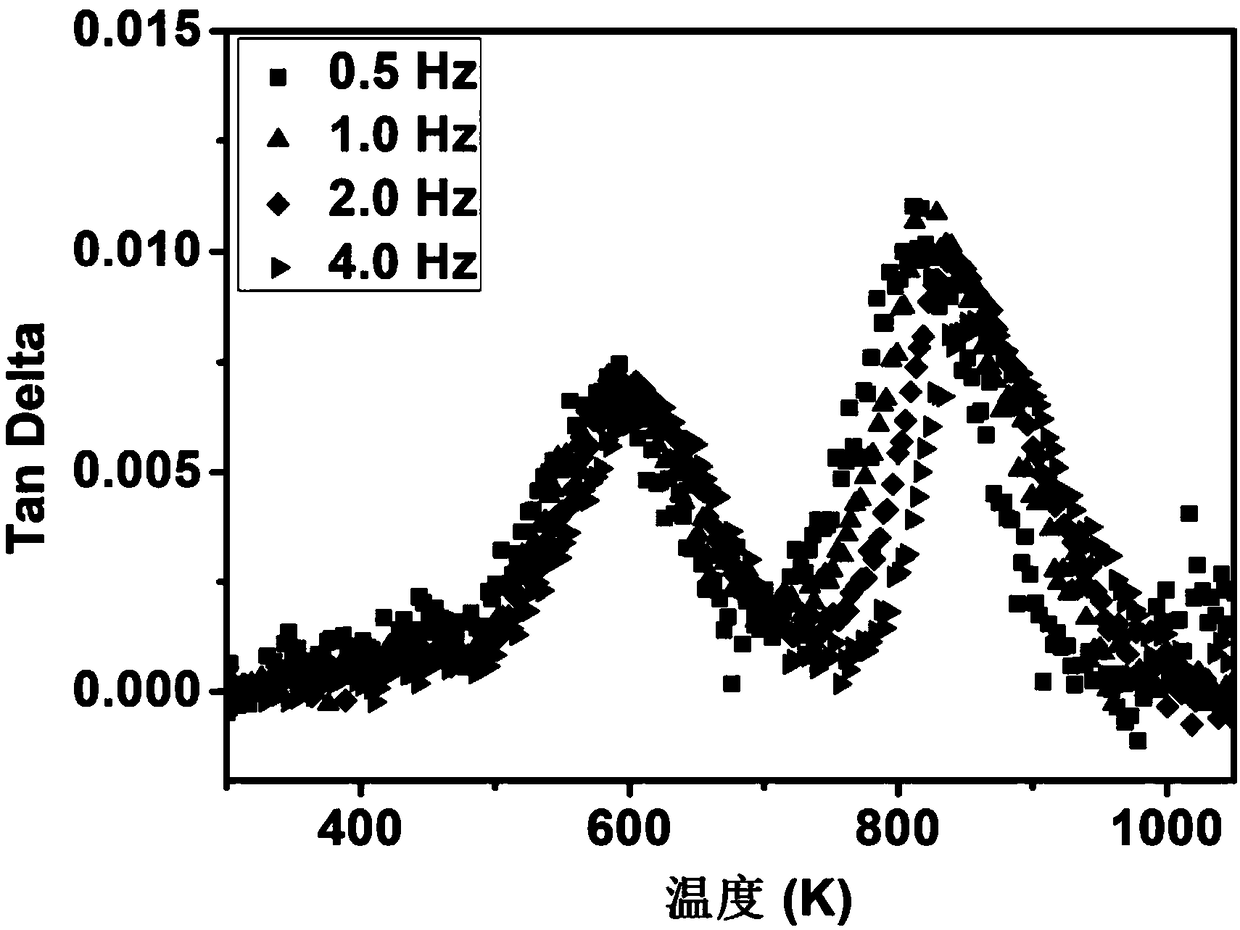

[0046] A kind of high temperature high damping high entropy alloy, its composition (atomic ratio) is: Ti 32.67 f 32.67 Nb 16.33 Ta 16.33 o 2 ,Such as image 3 As shown, its tanδ max ≥0.01, it is a high-damping alloy, and its damping relaxation peak temperature is greater than 700K, indicating that the alloy can also be used for high-temperature shock absorption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com