Preparation method of high-biocompatibility alpha-tricalcium phosphate nano-powder for 3D printing

A tricalcium phosphate nano, biocompatible technology, applied in prosthesis, medical science, additive processing, etc., can solve the problems of enhancing adhesion, increasing cell space, and the biocompatibility needs to be further improved. Achieve the effect of mild production conditions and low energy consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

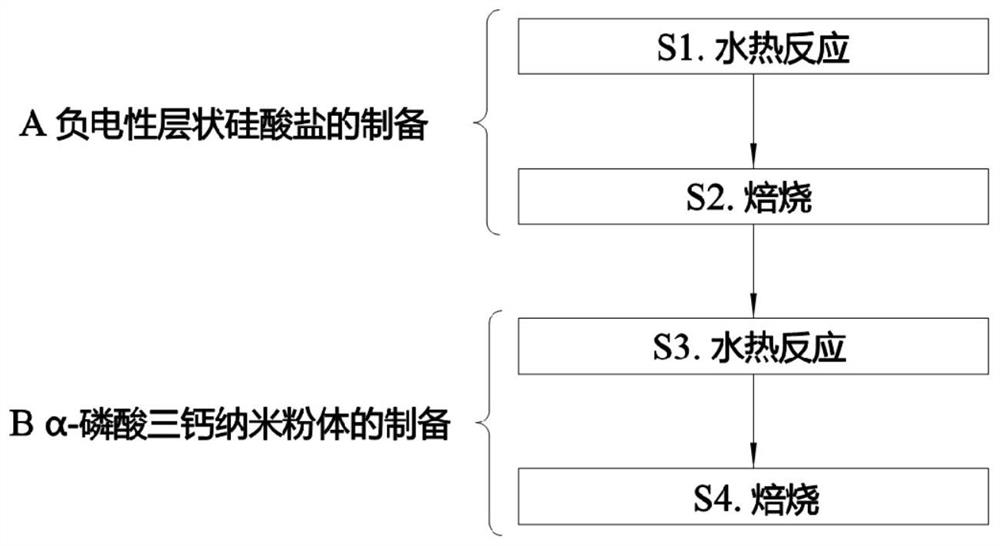

Method used

Image

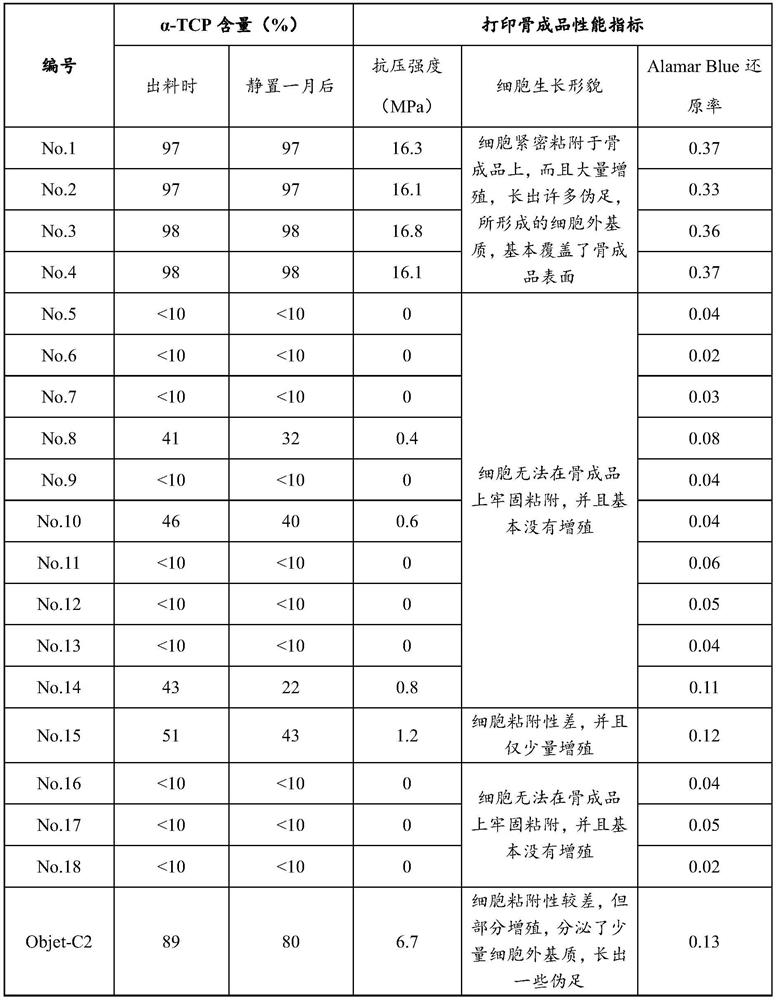

Examples

Embodiment 1

[0051] The preparation method of the highly biocompatible α-tricalcium phosphate nanopowder for 3D printing described in Example 1 is prepared according to the following steps from the following raw material components in parts by mass:

[0052] (1) First, 0.1 part of Ce(NO 3 ) 3 , 30 parts of tetraisopropyl titanate, 5 parts of sodium chloride and 500 parts of pure water are added to the hydrothermal reaction kettle and fully stirred evenly, and then 20 parts of Ca(NO 3 ) 2 And fully stir evenly, then airtightly raise the temperature to 120°C and keep it warm for 30 minutes; then stop the reaction and cool down to room temperature to discharge, first filter the reaction solution and wash it with alcohol, and then roast the collected filter cake at 120°C for 10 minutes, that is Negatively charged phyllosilicate 1# was obtained.

[0053] (2) Next, add 0.1 part of negatively charged phyllosilicate 1# prepared in the above step (1), 300 parts of calcium carbonate and 1000 part...

Embodiment 2

[0055] The preparation method of the highly biocompatible α-tricalcium phosphate nanopowder for 3D printing described in Example 2 is prepared according to the following steps from the following raw material components in parts by mass:

[0056] (1) First, 0.25 parts of Ce 2 (SO 4 ) 3 , 0.25 parts Dy(NO 3 ) 3 , 30 parts of tetrabutyl titanate, 30 parts of tetrabutyl titanate, 5 parts of sodium chloride and 500 parts of pure water are added to the hydrothermal reaction kettle and fully stirred evenly, and then 25 parts of Ca(NO 3 ) 2 and 25 parts CaCl 2 And fully stir evenly, then airtightly raise the temperature to 150°C and keep it warm for 60 minutes; then stop the reaction and cool down to room temperature to discharge, first filter the reaction solution and wash it with alcohol, and then roast the collected filter cake at 150°C for 30 minutes, that is Negatively charged phyllosilicate 2# was obtained.

[0057] (2) Next, add 0.5 parts of negatively charged phyllosili...

Embodiment 3

[0059] The preparation method of the highly biocompatible α-tricalcium phosphate nanopowder for 3D printing described in Example 3 is prepared according to the following steps from the following raw material components in parts by mass:

[0060] (1) First, 0.07 parts of CeCl 3 , 0.15 copies of Dy 2 (SO 4 ) 3 , 0.09 parts of DyCl 3 , 13 parts of tetrabutyl titanate, 26 parts of tetraisopropyl titanate, 5 parts of sodium chloride and 500 parts of pure water are added to the hydrothermal reaction kettle and fully stirred evenly, and then 11 parts of Ca(NO 3 ) 2 and 20 parts CaCl 2 And fully stir evenly, then airtightly raise the temperature to 130°C and keep it warm for 40 minutes; then stop the reaction and cool down to room temperature to discharge, first filter the reaction solution and wash it with alcohol, and then roast the collected filter cake at 130°C for 15 minutes, that is Negatively charged phyllosilicate 3# was prepared.

[0061] (2) Next, add 0.3 parts of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com