High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

A nano-precipitate, high-entropy alloy technology, applied in the field of high-entropy alloys, can solve problems such as the inability to obtain higher strength, and achieve the effects of excellent room temperature and high temperature tensile properties, wide preparation conditions, and large composition range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

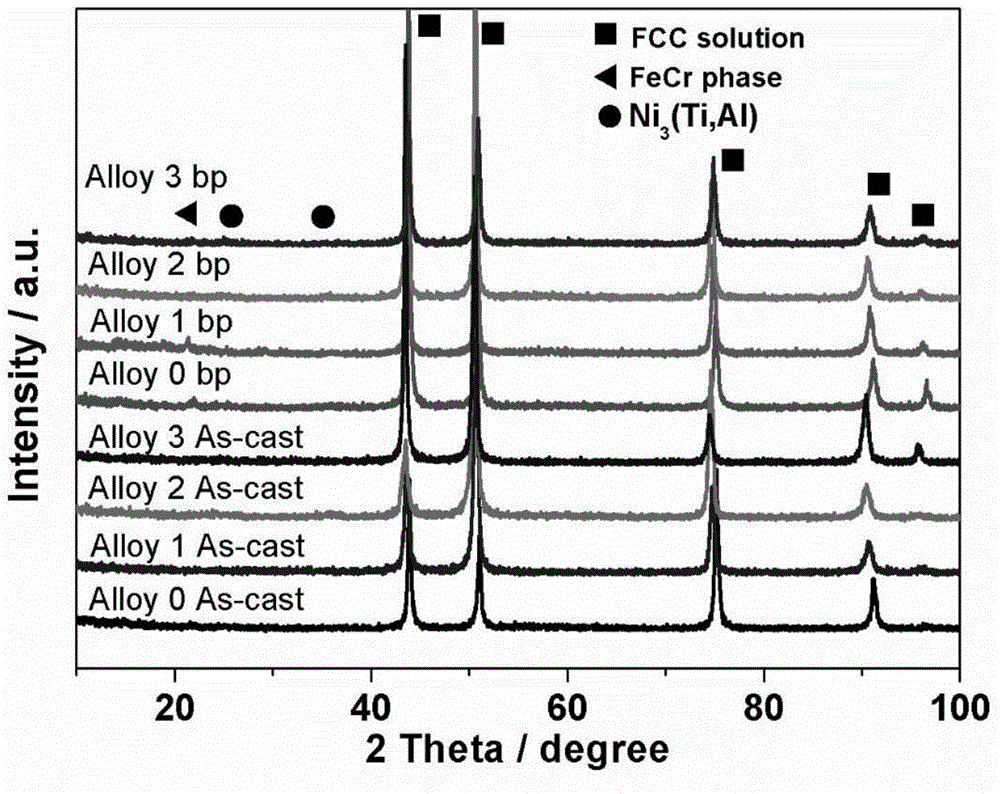

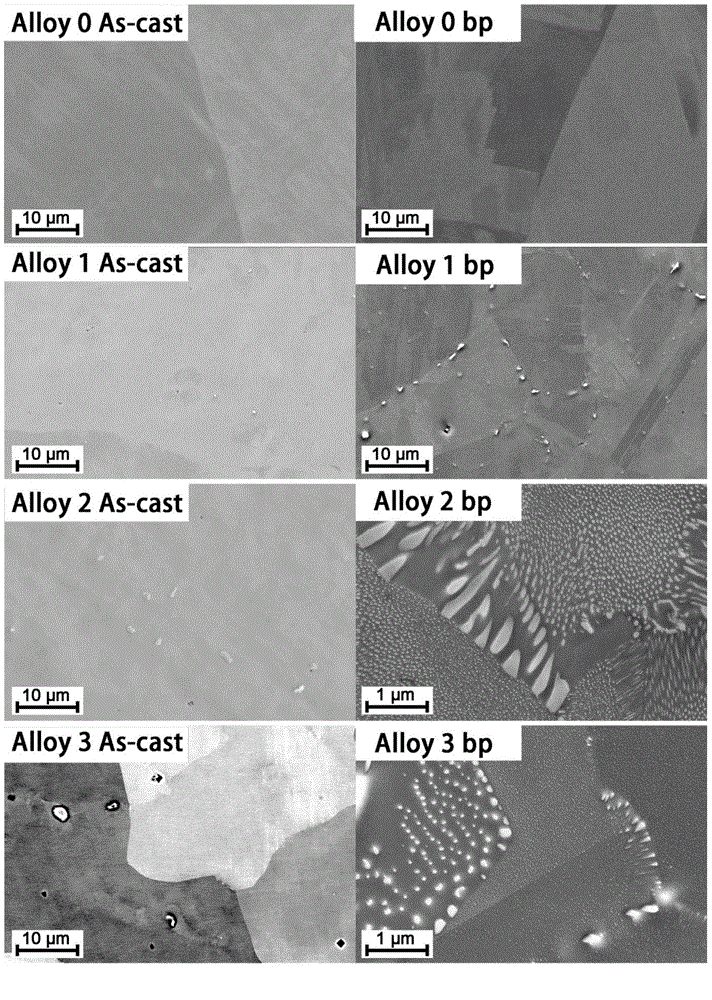

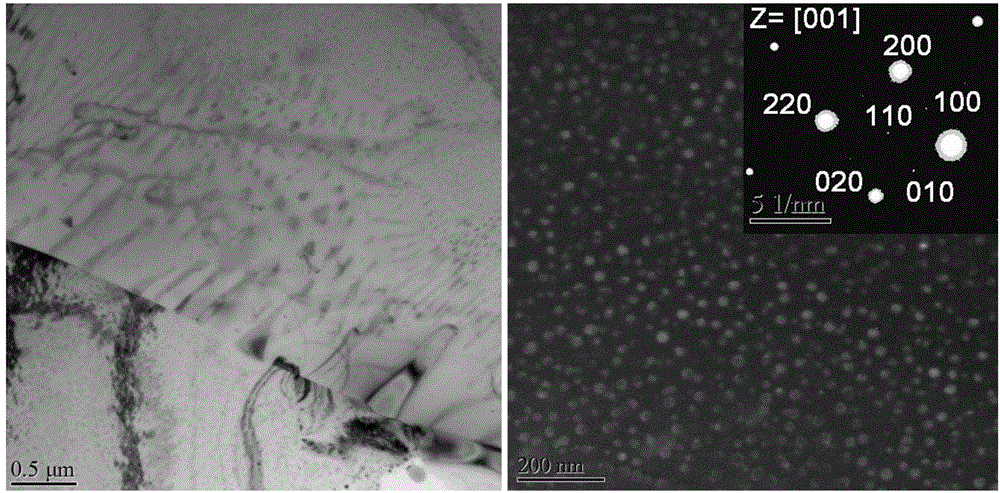

[0025] Example 1: Fe a co b Ni c Cr d Ti p Al q Preparation and Microstructure of High Entropy Alloys

[0026] Adopt commercially available pure metals Fe, Co, Ni, Cr, Ti, Al with a purity higher than 99.9% (mass percentage), according to the composition formula Fe a co b Ni c Cr d Ti p Al q(Atomic molar ratio, 0≤a≤35, 0≤b≤35, 0≤c≤35, 0≤d≤35, 0≤p≤10, 0≤q≤10) for batching, repeated arc melting 4 times Afterwards, it is leak-cast into a water-cooled copper mold of 10mm x 10mm to obtain an initial cast state high-entropy alloy ingot. Subsequent wire cutting into alloy sheets of suitable thickness, and cold rolling deformation of 30% reduction, heat preservation at 1000°C for 2 hours, quenching; heat preservation at 800°C for 18 hours, quenching, and finally obtain the dispersible alloy of the present invention. High-entropy alloys strengthened by nano-precipitates. figure 1 with figure 2 Alloys with different ratios of Ti and Al are shown respectively (a, b, c, d, ...

Embodiment 2

[0027] Example 2: Fe a co b Ni c Cr d Ti p Al q Mechanical Properties of High Entropy Alloys at Room Temperature

[0028] Common pure metals Fe, Co, Ni, Cr, Ti, Al that are commercially available with a purity higher than 99.9% (mass percentage) are used according to the composition formula Fe a co b Ni c Cr d Ti p Al q (Atomic molar ratio, 0≤a≤35, 0≤b≤35, 0≤c≤35, 0≤d≤35, 0≤p≤10, 0≤q≤10) for batching, repeated arc melting 4 times Afterwards, it is leak-cast into a water-cooled copper mold of 10mm x 10mm to obtain an initial cast state high-entropy alloy ingot. Then wire cutting into alloy sheets of suitable thickness, and 50% reduction of cold rolling deformation, 1.5 hours of heat preservation at 1050 ° C, quenching; 10 hours of heat preservation at 700 ° C, quenching, and finally the present invention has the dispersion High-entropy alloys strengthened by nano-precipitates. Finally, the high-entropy alloy with dispersed nano-phase precipitation strengthening des...

Embodiment 3

[0033] Example 3: Fe a co b Ni c Cr d Ti p Al q Nb e Preparation and High Temperature Mechanical Properties of High Entropy Alloys

[0034] Common pure metals Fe, Co, Ni, Cr, Ti, Al, Nb with a commercially available purity higher than 99.9% (mass percentage) are used according to the composition formula Fe a co b Ni c Cr d Ti p Al q Nb e (Atomic molar ratio, 0≤a≤35, 0≤b≤35, 0≤c≤35, 0≤d≤35, 0≤p≤10, 0≤q≤10, 0≤e≤35) for batching, After repeated arc melting for 4 times, it was leak-cast into a 10mm x 10mm water-cooled copper mold to obtain an initial cast high-entropy alloy ingot. Subsequent wire cutting into alloy sheets of appropriate thickness, and 20% cold rolling deformation, heat preservation at 950°C for 0.5 hours, quenching; heat preservation at 750°C for 6 hours, quenching, and finally obtain the dispersible alloy of the present invention. High-entropy alloys strengthened by nano-precipitates. Finally, the high-entropy alloy with dispersed nano-precipitatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com