Knuckle and bushing assembly

A technology of joint members and joints, applied in the field of integrated sleeves, can solve problems such as difficulty in achieving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

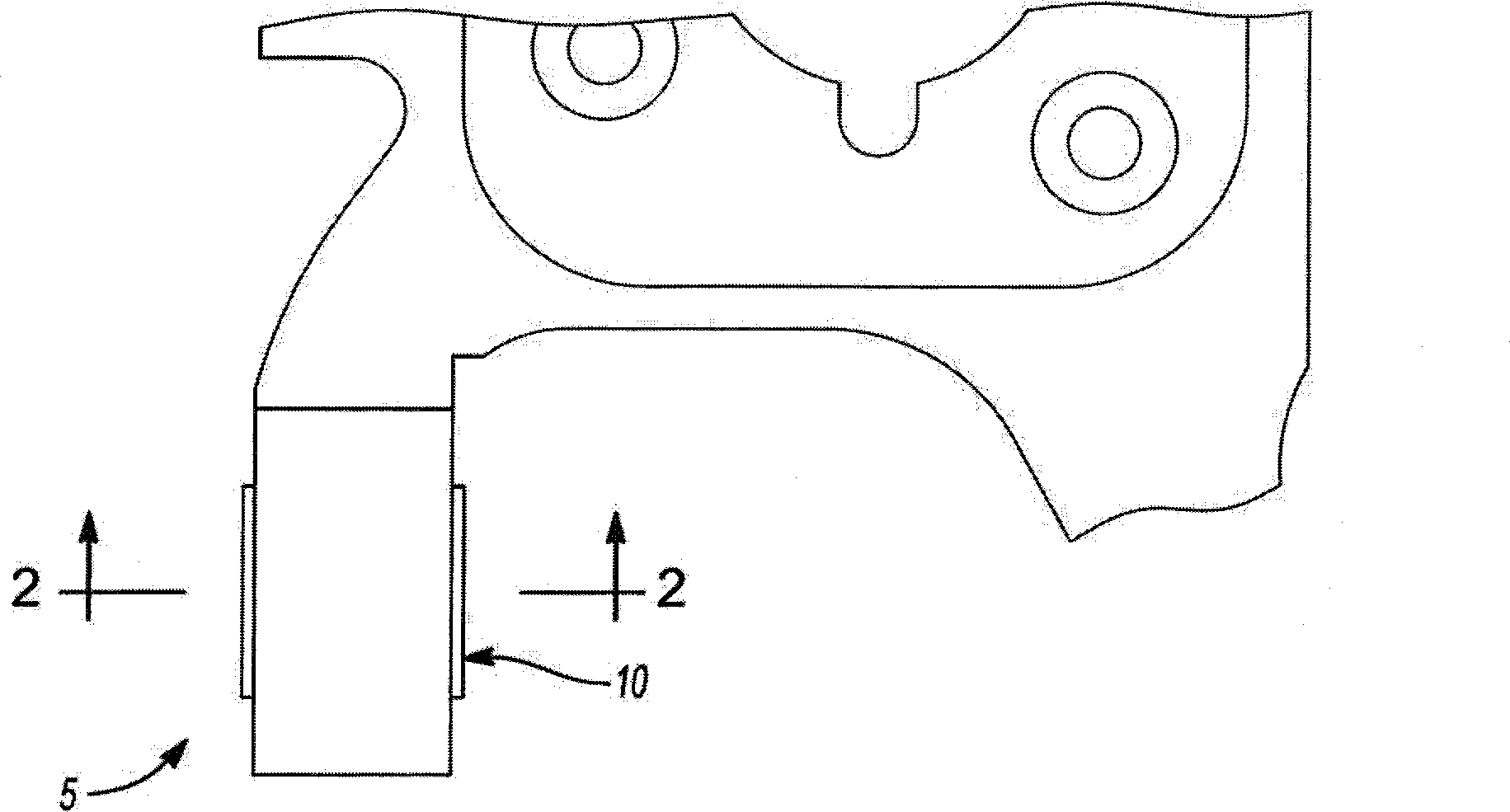

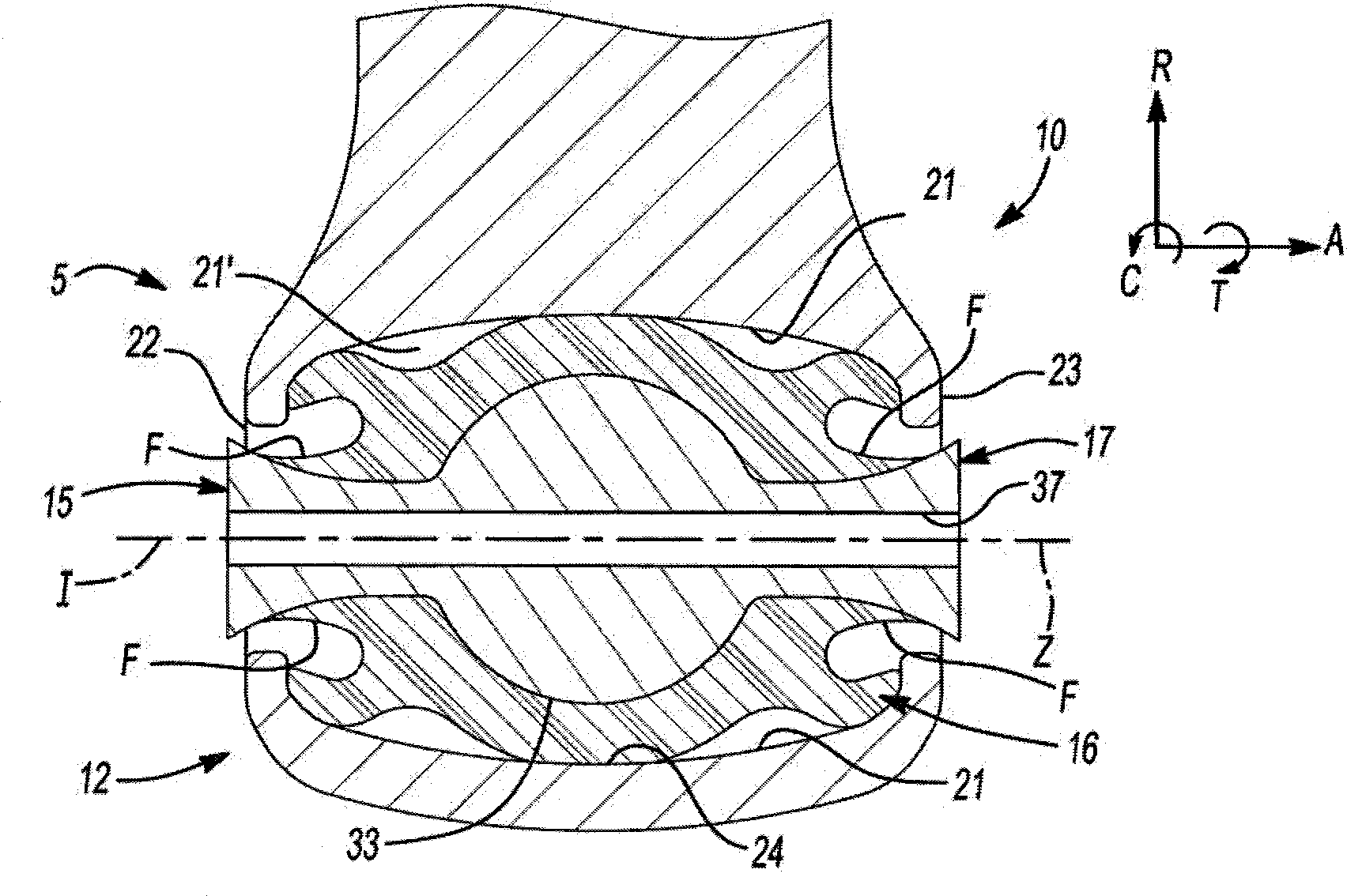

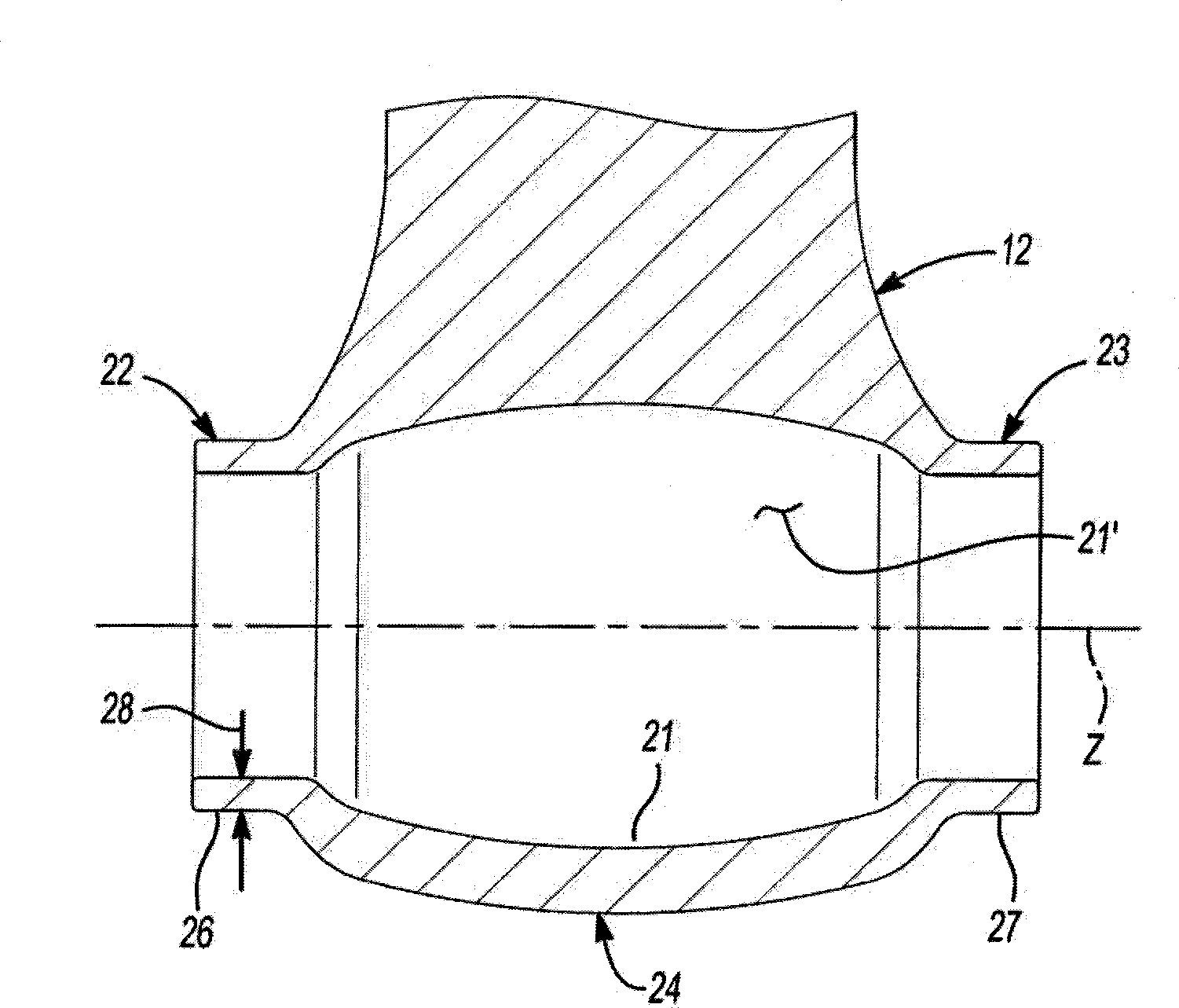

[0020] Suspension systems may be used in vehicles to provide a level ride for the vehicle by dampening or managing acceleration and deceleration of suspension components to manage pitch, roll, and yaw of the vehicle during varying operating conditions. Suspension systems typically include a number of suspension components such as control arms, pins, kingpins, struts, springs, dampers, steering components, wheel assembly components, mounting hardware, and / or other known suspension devices. The suspension components may be coupled together using any known or suitable coupling means. In one particular type of coupling, a hitch and hitch pin may be used to couple one suspension component to another suspension component. In one exemplary embodiment, one suspension component may include a hook and the other suspension component may include an articulation member that may use a hole located in each end of each arm or branch of the hook A hitch pin is coupled to the hitch. The hitch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com