Pivot bearing with plastic outer ring and method for its manufacture

一种关节轴承、外圈的技术,应用在轴承、轴承元件、轴和轴承等方向,能够解决限制轴承耐用性、昂贵、轴承没有足够精度等问题,达到良好机械加工的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

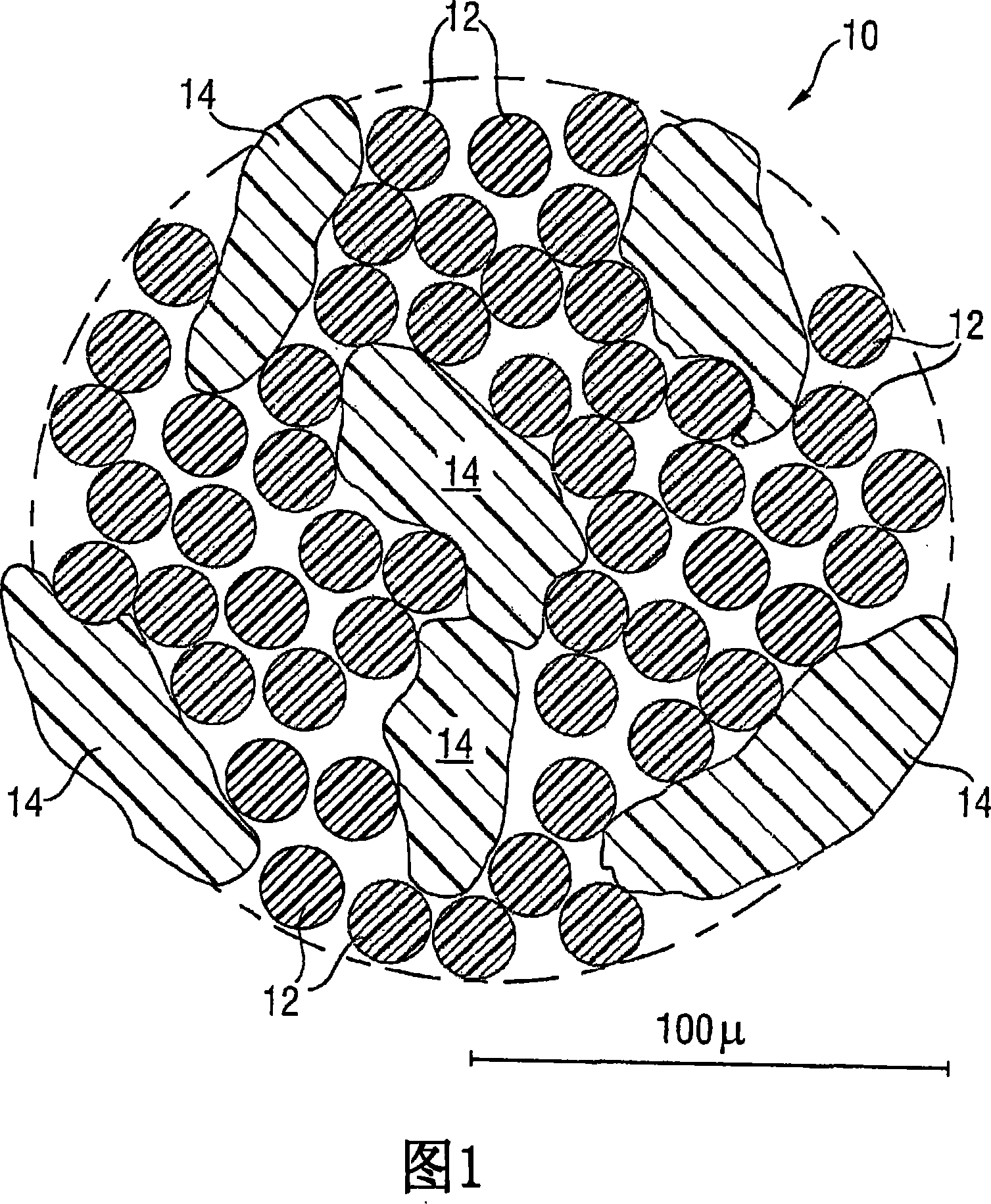

[0043] FIG. 1 shows a plastic filament 10 according to the invention as reinforcement for the outer ring sliding layer in an enlarged sectional view. The plastic filament consists of polyester filaments 12 oriented along the filaments and comprises as a second component PTFE particles 14 , which are woven into the polyester filaments 12 in a random arrangement. During the manufacturing process, there are numerous possibilities for changing the properties of the filament. For example, the number of polyester filaments 12 per filament 10 can vary depending on the application. In this connection, however, a sufficient form connection to the bonded PTFE particles 14 should be taken into account.

[0044] The weight ratio between polyester filaments 12 and PTFE particles 14 can likewise vary. However, it is particularly preferred that it proves beneficial, taking into account the adhesion, friction and sliding properties, if the percentage by weight of PTFE particles 14 in the pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com